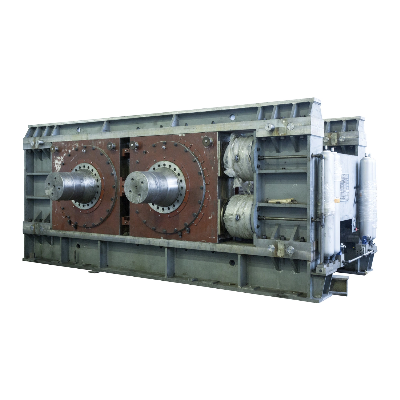

PFG120-50 High Efficiency Roller PressTechnical parameter for

φ1200×500 roller press Equipment name PFG120-50

roller press One Basic parameter of

equipment 1.1,roller

press Specification PFG120-50 Dimeter

of rollermmΦ1200 Length of rollermm500 Through

output≥t/h120-160 Rotor speedr/min23.56 Linear velocity

of rollerm/s1.48 Rance of working cleaning between

rollersmm15~30 Feeding sizemm≤45mm(≥95%) Discharging

sizemm≤2mm/0.09mm(65%/20%) Material

moisture%≤1% WeightKg68000Two Main part 2.1

Roller press 2.1.1Main

motor(2nos) Model Y355-8 PowerkW2×250 VoltageV6000 Rated

speedr/min750 Level of protection IP23 Weight

kg3500 Manufacturer Shanghai Motor 2.1.2Main

reducer(2nos) Model XGF38-31.5 Allowed

maximum transmission powerkW315 Nominal speed

ratio 31.5 Weight kg3500 Manufacturer Hubei

Jujin transmission 2.1.2.1 Oil station

Cooling water consumptionm3/h6 Power

kW4 Heater power KW2 Voltage V220(380) Manufacturer

Together with roller press 2.1.3Main

bearing(4nos) Model Bearing

23296CAK/W33 Weight kg835 Manufacturer Wa

Fangdian 2.1.5 bearing temperature measurement thermal

resistance (4nos) Model

WEPM-201 Index PT100 Temperature measurement

ºC0~100 External connection lengthmm1000 2.1.5Grease

centralized lubricating system Model of oil

pump PFDN-45Multi point lubrication pump Power

kW0.25 VoltageV380 Nominal pressureMPa20 Number of

lubricating points 14 Oil volume of each

spoutml0.16 2.1.7 Hydraulic system Motor

model Y160L-4 Power kW7.5 Voltage V380 Diameter

of main oil cylindermm¢320 Number of main oil

cylinder 4 Normal working pressureMPa12 Max working

pressureMPa16 Route of oil cylindermm70 Model of energy

accumulator /Volume/manufacturer NXQ-40/ 32L

/Zhejiang 2.1.8 Rollers(2nos) Parent

material 35 forging steel Structure:solid forging or

separated bushing solid forging or separated

bushing Weight kg8200 Hard facing thickness of roller

surface mm20 Hard facing hardness of roller surface

HRC50 Hard facing shape of roller surface Straight

stripe Lifetime of hard facing layer of roller

h≥8000 2.1.9 Bearing housing (4nos) Material

ZG270-500 Weight kg2800 2.1.10Mill

stand Material Q235-A Weight

kg12850 2.1.11 Feeding device Adjusting

valve Manual operation screw adjusting valve Material of

liner Wear resistant

material Lifetime 3000h 2.1.12 Electrical control

system Supplied with roller press 2.2 Weigh

bin Fabricate by buyer at site based on drawing provided by

seller. Model and number of sensors Supplied by

buyer Capacity t35 Weight kg6650 Scope of supply:

include complete set of roller press(include electrical control

system.)Company informationHere in Jiangsu Pengfei Group Co., Ltd,

we have a wide range of product lines for customers, and we provide

overall contracting services for cement production enterprises,

including technological design, equipment supply, and assembly and

debugging of equipment. And we undertake international biding

projects as well. Moreover, we also provide equipment and technical

service for grinding, calcining, crushing, dust collecting and

transporting in enterprises like metallurgy, chemical industry,

mining, electricity, and environment protection, etc.1. Cement

plant: for this line, we provide various services including

engineering design, civil construction, equipment, assembly and

debugging, technology services, and general contracting service.2.

Cement grinding plant: our cement grinding plant has advantages of

simpler processing flow, easier operation, less investment,

electricity saving, and environmental protection, and it can be

mixed with admixture.3. Industrial kiln and furnace: our industrial

kiln and furnace is widely used in fields like metallurgy, chemical

industry, building refractories, environmental protection sector,

and that.4. Grinding equipment: it is typically designed for

grinding various ores and grindable materials for industrial and

mining enterprises, and it can also be used for open-circuit

grinding as well as circulatory closed-circuit grinding in

conjunction with the powder classifier.5. Crushing equipment: our

crushers are typically designed for coarse and medium crushing of

ores and other materials.6. Dust collector: this kind of equipment

is typically used in fields like metallurgy, electricity, chemical

industry, building material, and many other sectors.7. Cooling

equipment: our monocular cooler has features of compact, rational

and simple structure, high thermal efficiency, low maintenance

costs, less equipment investment and high-efficiency operation. And

all of our coolers have the advantages of high efficiency and low

operation costs.8. Drying machine: our rotary dryer is mainly used

for drying slag, clay, limestone and more in fields of cement,

chemical engineering, metallurgy, building material, etc.9.

Compound fertilizer equipment: this kind of machine features easy

technology, low investment and convenient operaPictures of overseas

projects

Related products about Pfg 120-50 Roller Press/Rolling Machine Used in Cement Grinding System

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup