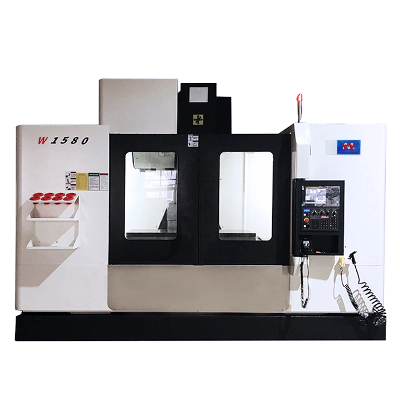

Product Description: Products Details

:

Description · Convincing

arguments: quality, efficiency and price · Imported high

rigidity screw, guide rail, coupling and other moving parts, good

stability and high precision. · High-inertia and high-torque

feed servo and processing capacity are superior to other

manufacturers' products of the same level.· Heavy duty roller screw

guides on three axis featured with both heavy cutting hard guide

and high speed & precision linear guide, low friction and long

service life· Components with CE certification.· The bus-type

system makes the electrical system more stable.· German technical

basic machine body, good rigidity and high precision.· Equipped

with 1ooooRPM high speed servo spindle as

standard, no noise.· The Z-axis of the machine tool has no

counterweights and no vibration during machining.· Conform to

European Safety

Standards(suitable for export) Appliation This VMC is

suitable for mechanical processing and mold making .And it can

asapt to the processing requirement from rough machining to finish

machining .It can also finish many working procedures like milling

,drilling ,tapping ,boring ,etc. Product

Parameters SpecificationW1580X/Y/Z-Axis

Travelmm1500/800/700Distance From Spindle Nose To

Tablemm150-850Distance From Spindle Center To Column

Guidewaymm855Spindle Motor Powerkw15/18.5Spindle

Speedrpm6000Spindle Taper BT50Positioning

Accuracymm/300mm±0.003Repeatability Accuracymm/300mm±0.0015Working

Table Sizemm1600×800Max. Working Table Load Capacitykg1000T-Slot

Qty-Width-Distancemm7-22-110X/Y/Z-Axis Rapid Feed

Speedm/min24/24/24Feed Speedmm/min1-10000Dia. Of X/Y/Z-Axis Ball

ScrewmmΦ50X/Y/Z-Axis Servo Motor Powerkw3.0/3.0/4.5Linear Guideway

Width And Type/Qty/Block QtyX-Axis55 Roller/2/6 Y-Axis45

Roller/4/8 Z-Axis55

Roller/2/6Controller FANUC,Siemens,Mitsubishi, GSK

OptionalMax. Power Consumptionkva50Net Weightton13Overal

Dimensions 4000*2900*3300Standard accessories Main

spindlebelt type8000rpmAutomatic tool change system ATCdisc tool

bank Oil water separation structure Coolant

systemstandard nozzle type spindle ring

spray automatic blowing nozzle typeoil

hazenozzle typeChip treatment front

chip Control system Mitsubishi

M80B Crystal operation

panel Handwheel Full cover protective

sheet metal Heat exchanger 3-color

warning light Water gun&air gun for

chleaning Gas storage

tank Optional accessories Min

spindle Belt type 10000rpmDirect connection12000rpmSpinle

cooling oil coolerAutomatic tool change system ATCBamboo hat

library Chip treatment Back

chip Control system FANUC OI MF Siemens

828D Guangshu , Xindai , Kaiendi Electric cabinet air

conditioner Automatic door Oil haze

recover device Safety door

lock Workshop picture Packaging &

Shipping FAQ 1:How can I choose the most

suitable machines ?A: Please tell me your specifications

,we can choose the best model for you , or you can choose

the exact model .You can also send us the products drawing ,we will

choose the most suitable machines for you . 2: What's your

main products of your company?A: We specialized in all kinds

of machines ,such as CNC Lathe Machine ,CNC Milling

Machine ,Vertical Machining Center ,Lathe Machines ,Drilling

Machine ,Radial Drilling Machine

,Sawing Machine ,Shaper machine and so on . 3: Where

is our factory located? How can I visit there?A : Our

factory is located in Yangzhou City ,Jiangzhou Province,

China. You are warmly welcomed to visit

us. 4. What is your trade terms?A : FOB,

CFR and CIF all acceptable. 5: What's the Payment

Terms ?A : T/T ,30% initial payment when order ,70%

balance payment before shipment ;Irrevocable LC at

sight . 5: What's the MOQ?A: 1 set .(Only some low cost

machines will be more than 1 set )

Related products about Vertical CNC Milling Machine Center /Cutting Machine /CNC Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup