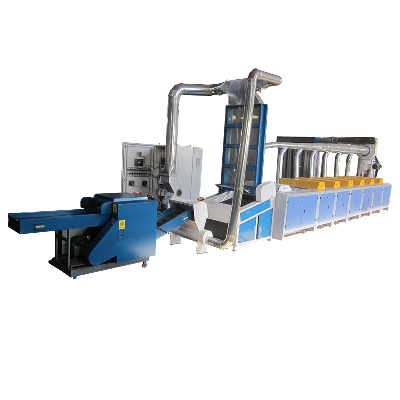

Textile waste recycling machine line Usage

and Features:The machine abolish the traditional processing

technology,use double roller opening design,realize the continuous

high-speed production,production of high and low adjustable

frequency conversion control.Any car automatically stop

feeding.Product design advanced,economical,low maintenance

cost.Products can be quickly opening various waste rags,waste

cotton yarn,old clothes,cotton,chemical fiber,linen,non-woven

fabrics and other scraps.Greatly improved the yield and quality of

the machine,it is equipment with dust filter to purify the

environment of the workshop,and improve the workers operating

environment.NOITEMDESCRIPTION1ModelRecycling

lineGM600N+6*GM250N2Installation dimensions

15110mm*2010mm*3050mm3Weight 7550KG4Total power 75KW5Working

widthR1040mm/ Unadjustable6 Main roller Openerφ600mm/Teeth

wireCleaning machineφ250mm/Teeth wire7Capacity150-220KG/H for

spinning productDepending on the raw material and product requirements(length

of fiber), also the correct operate8ProtectionRMain motor overload

protection Open phase protectionRPhotoelectric sensor induction

protection9Dust removal systemBy fans to out of workshop10Way of

controlConstant power & All Inverter control &PLC11Bearing

KOYO/Or according to the customer's requirements 12Electrical

components The key contactors by SIEMENS or according to the

customer's requirements13Inverter MAIFU 16months guarantee and

in guarantee send by DHL free PLCMITSUBISHI14Print

ColorAccording to the customer's requirements15The control cabinet

and panelDigital display instrument, and equipped with knob

regulator, professional electric schematic diagramProduct

Features:1-Output fiber with high quality,good fiber length.2-Adapt

to various raw materials.3-The motor and the reducer are equipped

with inverters,different procedures can be set according to the raw

material.4-Humanized human-machine interface,Production status

visualization.5-Adding metal removal system (magnet chamber and

magnet roller) and material humidification system to improve fiber

quality and protect the machineOur Sercive:1.We have After-sale

department,every client can get a timely feedback when they have

any trouble about our machine. 2.We have installation team,if you

need,we will provide installation service. 3.Our equipment warranty

period is 1 years,within this time,we will provide free

maintenance. 4.If you have any other question or demand,please feel

free to contact our businessmen,they will reply you within 8 hours.

Installation and Training Once we finalize

the production and delivery,we will assign 1-3 professional

engineers both in mechanical and electrical parts to the buyer's

factory for installation and samples test . And the engineers will

also train some skilled workers for buyer. The seller will explain,

operate and analyse in theory on the spot until the customer can

operate the equipment himself. The customer can consult with the

seller at any moment if they don't understand.We warmly welcome the

customer to come our factory to inspect the production line

before delivery . The machines only be delivered when the you

accept the quality of the machines and the product.Insist on

quality first the production standard, every machine before leave

the factory we test it ensure the quality is good. /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Rd Factory High Output Ce Non Woven Textile Waste Opening Recycling Machine for Tearig Yarn/Clothes /Cotton /Denim /Garment /Jute/Jeans /T-Shirt /Hosiery/ Fiber

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup