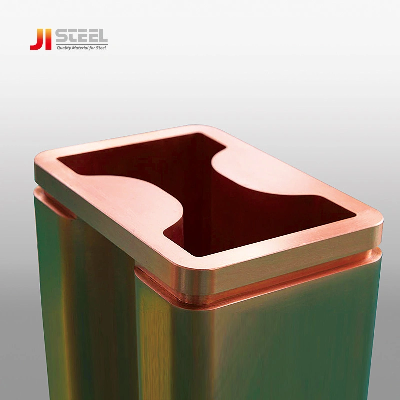

Product DescriptionBeam Blank Copper Mould Tube for

Continuous Casting Line to Produce Steel Billet Copper Mould

Tubes are the most essential part of a Continuous Casting Machine.

These help in solidifying Liquid Metal in Continuous Casting

Machine for producing Steel Billets. Copper

Mould Tube are situated in the heart of continuous

casting machine. Mould requires extreme high thermal-conductivity

and high strength. The molten steel will be formed into a certain

shaped steel billets immediately after it passes through the copper

tube. Copper Mould Tube Material:At present, Deoxidized phosphorus

copper (TP2), Silver-bearing copper (CuAg0.1) and Cu-Cr-Zr are

normally selected as the material to produce copper mould

tubes.TP2/Cu-DHP This kind of material is selected by most of the

steel plants. It shows excellent heat-proof and anti-fatigue

property under high temperature and it has good processing

propertyCuAgAdding 0.08%-0.12% silver during copper ingots

melting will increase the re-crystallization

temperature of copper by 100 ºC, which will increase the heat

stress and anti-abrasive property of copper mould tube interior

surface, showing better heat- resistant property than

Tp2.Cu-Cr-ZrCu-Cr-Zr is a kind of copper alloys which can be

normalized by time. It has excellent mechanical property under

both room temperature and high temperature. It has high heat

conductivity, melting point, anti-fatigue and anti-heat stress

properties. These outstanding features make it difffferent from

the previous copper alloys. It combines all good properties

together. But compared with other copper alloys, Cu-Cr-Zr is

difficult to be formed with higher products costs.Mould

CoatingsThe chrome plating thickness recommended by CCM will be

controlled in the best range. As for the coating of copper mould

plates, based on our 20 years of experience, we

can provide professional Chrome coating, Ni-Cr coating, Ni-Fe

coating and Ni-Co coating to meet the demand of various customers

both at home and abroadDetailed PhotosProduct ParametersCopper

Mould Tube

MaterialItemTemp.UnitMaterial CuDHPCuAg0.1CuCrZrChemical

Composition

P0.015-0.040Ag0.08-0.12Cr0.30-1.20 P0.04-0.012Zr0.03-0.30Physical

PropertiesElectrical conductivity20%IACS839580Thermal

conductivity20W/(m.k)340372330Coefficient of thermal

expansion20-30010'-6/K17.117.117.2Recrystallisation

temperature ºC345360690 Modulus of

elasticity2010'3MPa120123126Melting point

ºC108310831078Specific gravity g/cm38.98.98.9Mechanical

Properties Ultimate tensile strength

20Mpa240-310240-310375-445Ultimate tensile

strength100Mpa190-270230-270365-425Ultimate tensile

strength200Mpa140-190205-240365-410Ultimate tensile

strength300Mpa 175-210335-375Ultimate tensile

strength400Mpa 145-160315-3500.2Yield point

strength(Rp0.2)20Mpa190-250200-225280-3550.2Yield point

strength(Rp0.2)100Mpa185-260195-240270-3450.2Yield point

strength(Rp0.2)200Mpa 180-225260-3300.2 Yield point

strength(Rp0.2)300Mpa 165-215250-3200.2Yield point

strength(Rp0.2)400Mpa 130-145240-290Elongation(A5)20%25_1016_1020-13Hardness20HB80-95110-125115-130Our

Advantages1. The technical team of more than 20 people provides

customers with professional and cost-effective design solutions.2.

Each process has a special quality supervisor to strictly control

the quality.3. Perfect and timely after-sales service system,

24-hour response to customer needs, worry-free after-sales.Company

ProfileFounded in 2004, JI Steel has 20 years of professional

experience in the metallurgical industry and is committed to the

design, production, research and development of materials in the

metallurgical and steel industry, and provides a series of

high-quality, innovative and cost-effective products and solutions

for steel mills. The main products include copper mould tubes,

graphite electrodes, refractories for steel-melting and continuous

casting.JI Steel has 3 factories, nearly 10,000 employees, and an

independent scientific research and technical team of 50

people with rich experience in the metallurgical and

steel-making industries. It can provide customers with

customization, design, construction, installation, maintenance,

replacement, and technical consultation. and other services. JI

Steel has advanced CNC machining center, advanced production

technology, advanced water treatment system, and strictly controls

zero discharge in accordance with environmental protection

requirements to build a green and environmentally friendly

enterprise.Our products are recognized by SGS, OMIC, IKA, ISQI,

COTECNA and other well-known international inspection agencies, and

our products are exported to Europe, Asia, Africa, South America,

the Middle East and other countries, enjoying a good

reputation. Packaging & Shipping /* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Beam Blank Copper Mould Tube for Continuous Casting to Produce Steel Billet

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup