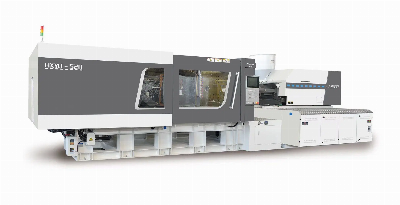

HXYD hybrid series of injection molding machineis a

new solution for high-end packing industry, high-end household

wares and medical suppliers industry, which was reserching and

developing on base of fully-electric (injection speed:500mm/s

,start producing since 2009) and highspeed series(start to

producing since 2012), combined with the clamping unit of

high-speed series and injection unit of fullly

-electric series , considerated with both of energy saving and

environment protection . it satisfies the needs of stronger

clamping force and higher performace of injection unit , provide

more energy saving and higher efficience (simulaneously mold

opening and charging).Product introduction 1 Modular injection

Unit with Excellent Acceleration Performance 2 High-stiffness

Clamping Unit for High-speed machine 3 Hydraulic System with

High Response and low Noise 4 Optimized Control syestem

Excellent in Response and Accuration for Hybrid Machine 1.The

injection unit uses ball screw and injection pressure sensor that

are imported from Japan,which can precisely control various actions

such as charging,injection,pressure maintaining and back pressure.

It has the advantages of low noise, high response, high repeat

precision and high service life. The repetition accuracy of

injection position can reach 0.01mm. 2.The platen optimized by

finite element analysis has the characteristics of high rigidity

and high strength.And the feet slipstructure of movable platen is

new designed oblique-wedge.It increases the support area and makes

the point forward.Whileloading the mod. it can effectively keep the

parallel precision of the mold-plate. 3.Adopt digital

communication non-contact displacement sensor for mold

open/clamp,which has feature of more fast and stable, higher

accuracy of position measurement and higher precision of

repetition. 4.It adopts the scecial control system of

electricity and oil hybnd machine and realizes tne dlosed-loop

control and data sharing of thecomputer controller, servo driver

and servo motor by Ether CAT bus communication, The control system

supports real-time energyconsumpticn monitonng and single product

energy consumption measurement, providing customers with accurate

cost calculation.

/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Plastic Injection Moulding Machine Hxyd520

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup