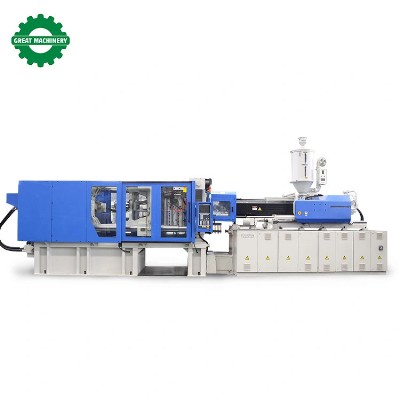

Great Price Fully Automatic plastic PP,PE,ABS Injection molding

machine Our Servo injection molding machine is energy-saving

machine. It was driven by servo motor, fit for production of

precise products. We will equiped transformer for change different

electricity power, such as 440V&220V Our energy saving

injection molding machines have some advantages make the choice! 1)

Energy Saving The pressure and flow differ in each stage of plastic

injection. The RPM of the traditional oil pump motor is invariable,

so the redundant oil just overflows into the oil and o lot of

energy wasted. Servo motor injection molding machine is able to

control the RPM by computer, thus the hydraulic pressure matches

the power needed in run, ensuring the quality of products with

lower energy consumption. Also, high sensitive pressure feedback

system helps achieving fast response close loop control. Energy

saving effect reaches to 30%~70%, especially more for products

needing long cycle time. 2) High efficiency The efficiency of the

traditional electromotor is very low, and the power factor will

contribute to the loss of power. However, the servomotor doesn't

have this problem and will improve the efficiency by 10% than that

of the traditional one. 3) Low Noise The noise is much lower than

that of standard injection molding machine. It operates with low

noise. Product Parameters UnitD400SITEMSABCINECTION

UNITScrew Diametermm65 70 75 Screw L/D RatioL/D23.7 22.0 20.5

Shot Size(Theoretical)cm31161 1347 1546 Injection Weightg1057 1226

1407 Injection PressureMPa221.8 191.3 166.6 Injection Rate into Air

cm3/s269.8 307.3 312.9 356.4 359.2409.1 Injection

Strokemm350 Injection Speedcm/s8.1/9.3Screw Speedrpm166

/189CLAMPING UNITClamping ForceKN4000 Clamping Strokemm750

Space Between Tie Barmm730*730Max. Mold Heightmm750 Min. Mold

Heightmm280 Eject Strokemm200Eject ForceKN124No. Of Ejector

Pinspiece13 OTHERSMax. Pump PressureMPa17.5 Pump Motor PowerKW33.5

37.0 Heater PowerKW24.2Hopper CapacityKg50 Oil Tank

CapacityL800 WeightT14.4Component PartsOur servo system was the

energy saving device that can save Min.50% electricity power for

larger models of injection molding machine Sample photoOur

AdvantagesLarge cutting and processing equipment, strictly

controlling the size,quality and processing quality for each

component part & mold platen!Packaging & Shipping /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Great Price Fully Automatic Plastic PP, PE, ABS Injection Molding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup