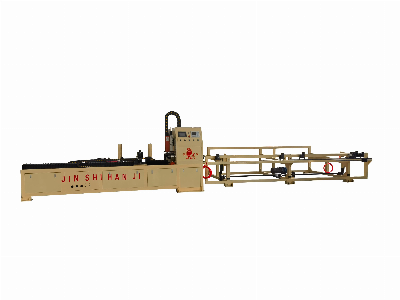

The equipment is mainly suitable for cutting Q345 steel pipe, the

equipment cut both ends of the steel pipe saw smooth, no burr,

reduce artificial grinding. Automatic production can be realized,

including automatic feeding, cutting, unloading, feeding, cutting

speed can be adjusted, reduce the work intensity, improve the work

efficiency, save costs.Product detailsScope of application: raw

material length: 5-7 meters. Tube diameter: Φ48 tube wall

thickness: 2.5-3.5MM.The cutting length is 500-3000 mm. (Can be

customized according to customer requirements)Equipment features:1.

Fast cutting speed, small cutting, save raw materials.2, adopt PLC+

industrial touch screen mode, man-machine interface; One-key

operation, simple operation, convenient, stable and reliable

performance.3. Automatic feeding and unloading. Reduce the

intensity of work.4, servo motor size adjustment, convenient and

fast, more accurate size.5. The cutting gun automatic follow up

system is added to make the cutting more smooth. Input power

supply Three-phase four-wire

380V±5%Compressed air (1.4 to 1.6Mpa) must be dry Spindle

speed 0-100/rpm (adjustable) servo control Spindle

rotation mode Servo drive Adjust the size positioning

mode Servo motor + gear and rack Clamping

mode Pneumatic chuck (0.4--08Mpa) Cutting head cooling

mode Water cooling Host size: length * width *

heigh 4200 * 1200 * 1600 Feeding modLeather wheel driven

by servo motor (speed adjustable) Feed drive motor 750W

servo motor + reducer Feeding platform size (L x W x

H) 5000*2000*1150 (welding of square pipe and steel

plate) Main configuration Main structure Box:

square pipe, steel plate Q235ACasting: HT250Pneumatic

system Cylinder, solenoid valve Electrical control

system Circuit breaker, contactor, key switch PLC, touch

screenlaser 3000W Cutting head 3000WServo

motor/driver 1500W/750Wchiller 3000WFrequently Asked

QuestionsQ1:What kind of machine I should choose?-Very easy to

choose. Just tell us what you want to do by using a laser cutting

machine, then let us give you perfect solutions and

suggestions. Different materials and different models apply to

the different machines. Please tell us what material you want to

cutting or engrave. And what's the MAX size of carved material? We

will recommend the most suitable model and the best price for

you.Q2:What can it cut? How thick can it cut at most?-Laser cutting

machines for metal usually deal with carbon steel, stainless

steel, aluminum, brass, and alloy. The maximum thickness is

different between different models and materials. Please check the

product introduction page.Q2:What can it cut? How thick can it cut

at most?-Laser cutting machines for metal usually deal

with carbon steel, stainless steel, aluminum, brass, and

alloy. The maximum thickness is different between different

models and materials. Please check the product introduction page.If

I have some problems, what should I do?-You can contact

our salesman directly, our engineer will check the problem. We

Provide proofing service before sale and free technical training,

online technical guidance, video guidanceQ5:How long is the

warranty?-We offer a 1-year warranty(except for the consumable

parts like Lens). The supplier will provide detailed information as

soon as possible. Product characteristics Faster cutting

speed, and higher efficiency, can save laborThe high degree of

automation, and low requirements for the operator.With a slag

pumping function, no burr in the incision, no slag hanging, and no

angle burning.The power consumption is less, and it's easy to

maintain. Packaging&Shipping1. Cleaning

machine.2. Wrap all the machine and parts with bubble film and

plastic film.3. Forklift the packed machine to the

container.4. Choose the optimal routes and transportation

modes according to the distance. Company honors and

qualifications: Company locationCompany introductionRenqiu

Jinshi Welding Manufacturing Co., LTD., located in Renqiu Economic

Development Zone, Hebei Province, covers an area of 100 mu, with a

total construction area of about 66,000 square meters. Founded in

1996, is currently the world's leading professional, scale,

complete types, strong scaffold equipment manufacturers, the

company set research and development, design, production, sales in

one. Has applied for the approval of the government research and

development institute, there are 1000 square meters of exclusive

research and development site. The company has more than 100

employees, including more than 20 core technology R&D personnel

and more than 30 on-site technical instructors. In addition, there

are 8-10 outsourcing processing plants that have been trained for

many years, with an annual output of 600-800 production lines.

Golden Lion has more than 20 invention patents and independent

intellectual property rights, and has been awarded the honorary

titles of "above the standard Enterprise", "High-tech Enterprise"

and "Key Protection Enterprise".With high quality products and

excelle

Related products about Metal Laser Cutter Machine CNC Fiber Laser Cutter Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup