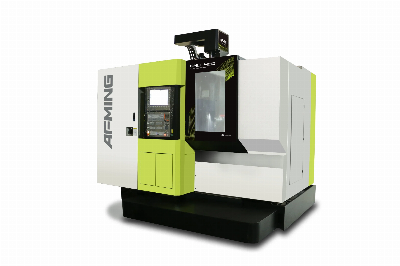

GMU400 CNC Vertical Machining Center Supply 5axis Milling

MachineIntroductionAchieve high-accuracy five-axis simultaneous

machining.Featuring a high-rigidity fixed beam gantry structure,

the GMU-400 Fearless series can realize high machining performance

and contour accuracy under highly dynamic conditions with high

accuracy, performance, and efficiency. More importantly, the

GMU-400 is equipped with the outstanding GTRT gear transmission

cradle technology as well to present an A-axis torque of 1056N.m

and a C-axis torque of 432N.m. From any difficult-to-cut material

to the highest surface quality required by mold manufacturing and

even the nearly exacting contour accuracy, the GMU-400 Fearless

series can deal with them perfectly.Finite element analysis

combined with dynamics optimization to ensure high rigidity, high

accuracy, and high stability. 1. High-rigidity fixed-beam gantry

structure is adopted to achieve excellent rigidity, thermal

symmetric stability, and high-efficiency vibration suppression. 2.

An integral cross beam with a closed section to eliminate redundant

mass and achieve high rigidity. 3. Moving parts optimized in terms

of weight to achieve perfect dynamic performance. 4. Z-axis

optimized in terms of mechanics and dynamics to gain 30% more

rigidity and dynamics than similar models. 5. Extra-large

area of vertical column base to provide stronger rigidity and

stability. 6. Finite element analysis, calculation and optimization

of whole-machine structure and moving parts to achieve high milling

efficiency, high machining performance, and extreme accuracy. 7.

First-order natural frequency of the whole machine up to

67HZ, which has greatly improved the anti-seismic performance and

the static and dynamic rigidity of the machine tools. 8.

Three-axis acceleration up to 1.2G. GTRT Gear Transmission Rotary

Table Technology.The GMU-400 has adopted the GTRT gear transmission

rotary table technology for the first time in its class. Compared

to the conventional rotary table drive ones, it can present greater

torque output, higher rigidity, higher stability and better

rotation precision. GTRT gear transmission rotary table A-axis:

Servo motor + DIN5 grade grinding gear (two-stage anti-backlash

patented technology) C-axis: Servo motor + DIN5 grade

grinding gear (two-stage anti-backlash patented technology)

Travel (A/C): ±120°/360° Maximum RPM (A/C): 20/30rpm Maximum torque

(A/C): 1056 /432 N.m Accuracy (A/C): 8"/4" Bearing capacity: 120kg

Easy operationBased on ergonomic design, it has achieved

extraordinary processing proximity and visibility as well as

unrivalled ease of operation experience.Detail ImagesApplication

FieldsIt is widely used in the processing of 3C products, aluminum

alloy products, die-casting products, auto parts and so on.It's

applicable for high-speed drilling and tapping processing.Technical

SpecificationsNameUnitGMU-400X/Y/Z-axis travelmm450/500/350A/C-aixs

travel °±120/360Spindle nose to table (when A axis is at 0

degree)mm150-500Table sizemm0400Maximum load

bearingkg120SpindleSpindle (standard)Maximum spindle speed/taper

shankrpm30000/HSK-E40Spindle power (S1/ S6 - 40%)KW10/13Torque (S1/

S6 - 40%)N.m5.5/7.1Spindle (optional 1)Spindle (optional 1)Spindle

(optional 1)Maximum spindle speed/taper

shankrpm40000/HSK-E32Spindle power (S1/ S6 - 40%)KW6.3/7.6Torque

(S1/ S6 - 40%)N.m4/4.8Spindle (optional 2)Spindle (optional

2)Spindle (optional 2)Maximum spindle speed/taper

shankrpm24000/HSK-A63Spindle power (rated)KW15.7/18.8Torque

(rated)N.m25/30Feed systemX/Y/Z-axis rapid feedm/min30/30/20Maximum

cutting feed ratem/min10Accelerationm/s25Maximum cutting feed

rateRPM/min20/30Positioning accuracy / Repeated positioning

accuracy VDIDGQ3441/iso

230-2X/Y/Zmm0.006/0.003A/CARCSEC8/4Automatic tool changing

systemNumber of tool positionsPCS16TTool change time

(tool-to-tool)sec4.5SMaximum tool lengthmm200Maximum tool diameter

/adjacent no toolmm060/0100Maximum tool weightkg3Machine

sizeOverall machine heightmm3100Floor area (Length ×

Width)mm^23100x2400Net weightkg8000Power demandkw25Configuration

ListNO.Standard ItemsOptional Items1Siemens 840D SystemHeidenhain

TNC640 system2Uncapped full enclosure machine body sheet metal

(including water tank)HSKE32-40000RPM electric

spindle33HSKE40-30000 RPM electric spindleHSKA63-24000RPM electric

spindle4A/C cradle-type rotary tableCapped full-enclosure

programmable top guard5Spindle cooling systemLaser-type tool

setting gage6A/C-axis optical scaleSafety gate switch7Five-axis

calibration kitOil collector8Three-axis linear optical scaleOn-line

measurement9Z-axis balance systemFive-axis anti-collision

function10Electric cabinet constant temperature systemPower-off

retraction system 11Pneumatic systemCoolant through spindle

(CTS)12Automatic lubrication systemScraper type chip

conveyor13Machine cleaning water gun 14Machine cleaning air

gun 15Working light 16Warning light 17Tool box and

foundation bolts 1816T horizontal umbrella-type tool

magazine 19Drawer

Related products about Gmu400 High Precision CNC Milling Machine Lathe for Metal Hardware

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup