Best Selling Turret Busbar Punching Bending Shearing MachineProduct

Description ZTMX Turret Busbar Machine1. The

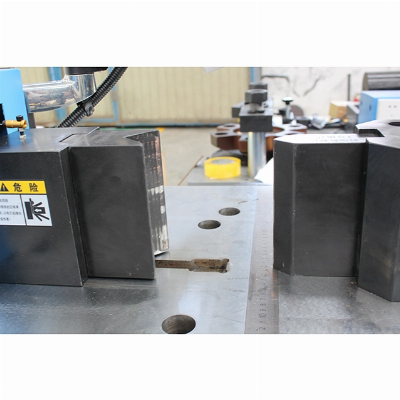

shearing unit adopts the double column double knife shearing

structure, the upper and lower knives are installed vertically and

parallel to ensure a smooth cut, and no burr, no waste

generation.2.The punching unit adopts six die positions of integral

turntable, (the turntable is an integrated processing parts, mold

mounting holes for CNC machining center, high precision, mold and

turntable with a clearance of 0.00-0.05mm), improve the

concentricity of the mold, prolong the service life , in addition

to the use of frequent replacement , improve efficiency. 3.The

bending unit adopts closed bending, and the output point and the

stress point are connected by a 50mm thick cross beam, which

greatly enhances the mechanical strength compared with open

bending. 4.The three working stations of the machine can work

simultaneously, which greatly improves the working efficiency.5.The

hydraulic oil tank is welded with thick steel plate and phosphate

treatment, so that the hydraulic oil will not deteriorate in

long-term use. 6.The three processing units of punching, shearing

and bending are all controlled by a double foot pedal,In the case

of automatic control mode, even if the upper and lower limits of

each station are disconnected, it will never affect the user's

production use, thus reducing the failure rate of the equipment and

eliminating the safety hazards such as the rupture of the oil pipe

of the pump that occurred in the past when the limit switch of the

equipment failed. In the case of manual control mode, the operation

of each station is simple and convenient, thus improving production

efficiency. 7.This type of machine is divided into two models,

ordinary type and CNC type, and the CNC system is a Taiwan product.

8.The equipment is equipped with a jacking and leveling device,

easy to install. Detailed Photos

Workpiece: Product Parameters

Model ZTMX-301 ZTMX-303 ZTMX-501

ZTMX-503 Max.punching force 350 350

500 500 Hole punching diameter Φ4.3-φ35

Φ4.3-φ35 Φ4.3-φ36 Φ4.3-φ36 Max.punching

thickness 12 12 18 18 Max.

shearing thickness 12 12 18 18

Max.shearing width 160 160 260 260

Max. bending force 350 350 550

550 Max. bending width 160 160 260

260 Max.bending thickness into flat bend16

16 20 20 Max.processing size of

vertical bend125*12 125*12 125*12 125*12

Main motor power4 4(3 pcs) 5.5 5.5(3

pcs) Machine weight approx.1.2 1.4 1.8

2.2 Dimension1800*1400*1300 1800*1400*1400

2000*1500*1400 2000*1500*1500 1 level worktable size

1770*1240 1770*1240 1840*1450 1840*1450

2 level worktable size / 890*500 /

1000*500 Shearing,punching and bending work

simultaneously / yes / yes

Packaging & Shipping Company Profile Shandong Raintech

SANS Technology Co., Ltd is a professional manufacture for CNC

machines with more than 13 years' experience. The factory

established in the year of 2008, has been devote to the research

and production of the advanced CNC machines which can save the

production cost and time in steel industry applicationWe answer our

nation call of "Made in China 2025"plan, adopts intelligent

information technology to improve the machinery industry , our

machines widely used in Uhv power transmission and transformation

steel tower, electrical iron fittings, wind power machines, traffic

railway construction , steel structure construction, three

-dimensional parking system, central air conditioner system, sea

water desalination, Petroleum and petrochemical , construction

machinery, project machinery and port machinery , Modern granary,

shipbuilding etc.Our brand reputation in advanced leading position

in the field domestic, also becoming an important role on

international market, the products have been exported to more than

20 countries and area in the world. The company pay great

attention on the technique research and quality, have own many

patents on many products depends on our plenty experience in

research and management of manufacturing. Our patent of "combined

production line for flat bar, angle steel and channel steel,CNC

integrated line for flat bar and clamp making,redefined the

processing technology of electrical iron fittings.Our machines

realize the multifunction and multi-process automatic continuously

production, through fully automatic functions including detection,

infeed and outfeed, processing, stacking, data control etc. and

additionally data collection and organization. We have been

developed to be an digitized, intelligent, BNR , integrated and

high efficiency green manufacture. Our Main Products

Including :CNC machines for tower &steel structure : Turret

Busbar machine,CNC angle steel punching , shearing, marking line,

CNC flat bar punching, shearing and marking line, CNC high speed

planar drilling machi

Related products about Best Selling Turret Busbar Punching Bending Shearing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup