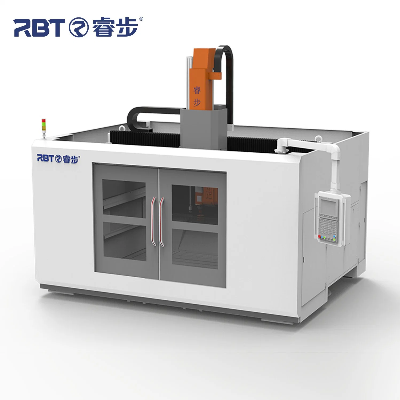

Truss Type 5 axis cnc machining center Technical

ParameterMachine Function1. Non-metal five-axis machining center,

when working, five coordinate axes drive the tool to move around

the workpiece, and can realize five-axis linkage three-dimensional

movement, which can meet the processing of pentahedron and

arbitrary curved surface.2. The system adopts SYNTEC five-axis

linkage CNC system. The machine combines power, speed and precision

and can be equipped with multiple functions such as dust

collection, automatic tool change and RTCP. It can cut

difficult-to-process materials in the shortest time to obtain very

high-precision contours and profiles. The multi-face processing of

the entire product can be completed in one clamping.3.Processing

the thermoformed plastic or composite material products for

three-dimensional or multidimensional special-shaped cutting,

drilling, trimming etc. 4. RBT five-axis machining center

spindle is imported spindle, fast speed, high precision.5.Drilling,

especially side drilling, need spindle swing Angle, five axis

machine tool is imported double swing head spindle, can achieve

360° swing Angle, drilling processing.6.The machine is truss type

and has a solid structure, good precision and reliability, high

safety, meets the requirements of environmental protection work,

and is suitable for milling, window opening, contour processing,

finishing, drilling and 3D machining for any non-metal

material.Machine Features of Truss Type 1. The truss-type

structure with protection room, fixed worktable, and semi-enclosed

protection design meet the safety protection and debris prevention

during production and processing. 2. The truss double Y, X, Z,

C, B six axes form a double swing head type five-axis machining

body.3. During processing, the work table does not move, and the

five coordinate axes drive the tool to move around the workpiece.

It can realize five-axis linkage three-dimensional movement, which

can meet the processing of pentahedron and arbitrary curved

surface.4.Integral floor drain dust collection device cooperates

with high-performance dust collector to collect processing

debris.Machine Applicable to punching, cutting and trimming:

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass

fiber, carbon/carbon, etc.;Plastics: ABS, PVC, PC, PP, PS, PE, PET,

HDPE, PETG, Acrylic etc.;Other non-metal material: high-density

sponge, Styrofoam foam, wood, substitute wood, stone, plaster

etcMachine Widely used in:Mold manufacturing, composite material

processing, and thick sheet thermoforming processing in industries

such as aerospace, rail transit, automotive interior and exterior,

sporting goods, medical beauty, white goods, handicrafts, and

sanitary ware.Successful Cases: CE Certificate: Position

measurement and calibrition by laser

interferometerWORKSHOP PACKING & DELIVERY1.Plastic film

packaging and put in plywood wooden cases or according to

customer's requirements.2.Shipping : Container

transport.Representative CustomerFAQQ1. Where is your factory

located ? How can I visit it ?A : Our factory is located in

Quanzhou city,Fujian province,China. You can fly to Jinjiang or

Xiamen air port, we will pick you up.Q2. Are you produce the

machine according to the customer requirement or samples?A: Yes,we

have a strong and professional R& D team, the machine can be

customized based on your products, samples or technical

drawings. Q3. What is your sample service?A: We can

supply the sample testing based on your technical drawing and

samples to test the machine performance. Q4. What is your MOQ

of your machine?A: Normally our MOQ is 1 set.Q5. Do you test all

your machine before delivery?A: Yes, we have 100% test before

delivery.Q6: How is your development ability? A: We have a

strong and professional engineer team to support the drawing,

technology proposal, test and certification; OEM or customized

machines are welcomed. Q7: How about your after sales

service? A:For online services, the supplier will support

WeChat/WhatsApp/email or communication software that used by the

buyer, including video guidance, video conferencing, etc.

If need technology support on site, the

supplier will send technician to the buyer's factory for

installation, training and after-sales service. The service period

is 7 days. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Five-Axis CNC Machining Center

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup