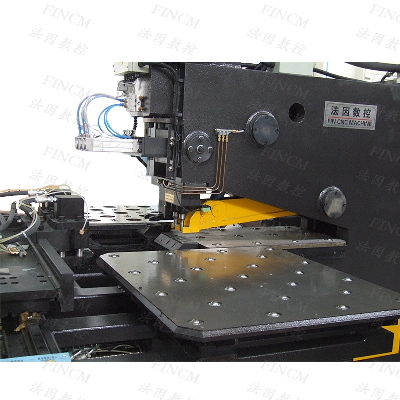

PPD103B FINCM Transmission Line Steel Plates CNC Punching Drilling

And Marking Machine 1500mm*775mmProduct Description Three

die-stations which can punch holes with three different

diameters.Or as an option,using two punches and one char-

acter-box,thus the machine can mark simultaneously while

punchingMain Technical Specifications:Max. Punching Force1000kNMax.

Size of Workpiece775×1500mmThickness of Workpiece5 ~ 25mmMax.

Punching Diameterφ25.5mmNo. of Die Station3Min. Distance Between

Hole and Plate Edge25mmMax. Punching Force800kNNo. of

Character Dimension 10Drilling Diameterφ16 ~

φ50mm Rotation Speed of Drilling

Spindle120~560r/min, 5.5kWMax.Stroke of Drilling

Spindle180mmFeeding Speed20~200mm/minMotor Power of Hydraulic

Pump15kWThe Servo Motor Power of X and Y axes2×2kWThe Compressed

Air Force × Discharging Quantity0.5MPa×0.1m3/minOverall

Dimension (length × width ×height)3100×2988×2720mmNet

WeightApprox.6500kgThe motor of X and Y axes are world famous brand

AC servo motor. The main electric controlling components (PLC and

CNC orientation system, encoder and switch without touching),

hydraulic components, pneumatic valve (electromagnetic valve,

overflow valve, and unloading valve) and cylinder are all world

famous brand.Working environment:

Working temperature: 0ºC ~ 40ºC

Power: Three phase four wire system

AC Voltage: 380V

Fluctuation of voltage: ±10%

Frequency: 50 HzList of the Key Outsourced

Components:No.NameSpecificationQuantityBrandCountry1Linear

guideMSA304PMITaiwan China2Oil

pumpT6CCW-017-0061DenisonAmerica3Solenoid relief

valveAGAM-10/21/350/2101AtosItaly4Solenoid unloading

valveAGIU-20/10/1001Atos/YukenItaly/Taiwan

China5SolenoidValve(Dg6)SDHE-1631/21Atos/YukenItaly/Taiwan

China6Solenoid Valve(Dg6)SDHE-07141Atos/YukenItaly/Taiwan

China7Solenoid Valve(Dg6)SDHE-07131Atos/YukenItaly/Taiwan

China8One-way throttle valveHQ-0121AtosItaly9Throttle Valve of

PTVP-021JUSTMARKTaiwan China10One-way valve of

PCVP-02-B1JUSTMARKTaiwan China11Check valvePCVA-02-B1JUSTMARKTaiwan

China12Air valveSY5120-5DD-013SMCJapan13Confluence

plateSS5Y5-20-031SMCJapan14CylinderCP95SDB40-1003SMCJapan15Filter-Regulator-Lubricator

combined unitsG1/41SMCJapan16AC servo motor2kW2S

chneiderFrance17Program

ControllerFX1N-60MT1setMitsubishiJapan18TransducerMMX440(5.5kW)1SiemensGermany Note:

The above is our fixed supplier. If the supplier can not supply the

components in case of any special matter, we will adopt the

components with the same level, but the quality is no worse than

the above.Relateed ProductsCompany Profile Shandong

FIN CNC MACHINE CO., LTD. is always focusing on our ultimate goal -

to secure and increase our customer's productivity - has made us

the leader in China market in the manufacture of machines for

processing angle bar, beam channel profiles, steel plates,

tubesheet and flanges, mainly serving for fabricating iron towers,

steel structure, heat exchangers, boilers, bridges, and

trucks.Strong R & D center with 30 engineers team, 24 years of

experience from year 1997, 280 staff, plant area about 270,000

sqm., very harsh quality control of every component and the whole

machine, about 40 million US dollars sales turnover per

year. FIN CNC machines' market share in

China is around 70% and exported to 50+ countries across globe

market. All top ranked tower manufacturers, steel structure

fabricators and power station makers, bridge/railway manufacturers,

truck makers are our clients. Main products: CNC

Angle Line, CNC Beam Drilling Sawing Machine, CNC Plate Drilling

Machine, CNC Rail Processing Machine, CNC Tubesheet Flange Drilling

Machine, Truck beam plate punching machine, etc..One measure of the

outstanding quality of our machines is their longevity: many FIN

machines have been in operation for more than 17 years! Many

clients are continually placing repeated orders which verified well

our machines' perfect quality and reliable

performance. The company drafted many China

national standards for CNC angle line machine and CNC beam drilling

sawing machine and CNC plate drilling machine.Cooperatine

SupplierProduct Process ControlCustomer Praise Sales

NetworkOur Service FAQ: 1. When can you arrange

shipment? For machines available in stock,

the shipment can be arranged within 15 days after getting advance

payment or L/C; For machines non available

in stock, the shipment can be arranged with 60 days after getting

advance payment or L/C.2. What can you do if my machines have

problems? 1) We can send you free components if

machines are in warranty period; 2) 24 hours

service on line; 3) We can assign our engineers

to serve you if you want.3. Do you provide machine operation

training? Yes. We can send professional engineers

to the working site for machine's installation, commissioning and

operation training.4. Which machine model shall I choose when I

purchase from you? Please share us your material

size and your processing request, then

Related products about High Voltage Tower Plate Punching Machine FINCM CNC Hydraulic Hole Steel Plate Punching Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup