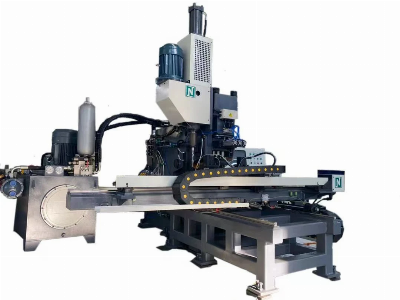

Product parameters1. Technical Specification of PPD103B1.Max.

punching force:1000kN2.Max. size of workpiece:775×1500mm3.Thickness

of workpiece: 5 ~ 25mm4.Max. punching diameter :

φ25.5mm(16Mn,20mm thickness Q235, 25mm thickness)(we only provide

the die of 16mm thickness for test run. If you want the die

of 20mm,25mm thickness for test run, you must provide

the female die yourself) 5.No. of die station: 3(one of

them can be equipped with stamping die)6.Min. distance between hole

and plate edge

Punching:

25mmDrilling: the distance depends on the hole diameter

7.Max. marking force:800kN8.No. and size of character: 10

(14×10mm)9.Drilling diameter (high-speed steel twist drill): φ16 ~

φ50mm10.Rotation speed of drilling spindle (stepless speed

variation):120~560r/min, 5.5kW11.Max. stroke of drilling

spindle:180mm12.Feeding speed (hydraulic stepless adjustment)

20~200mm/min13.The processing precision:It can fit the stipulations

of first-rate products in < The Classifying Standard of Steel

Tower of the Transmit Electricity Line >. The specific numerical

value:The space between arbitrary holes on the joint plate:

longitudinal: ±0.5mm transverse : ±0.5mmNode

plate: space between any two group holes : ±1.0mm, the

space of the hole to the side of the steel plate: ±1.0mm1. The

vertical degree, "t" is the thickness of plate ≤ 0.03t and ≤

2mm2.Motor power of hydraulic pump:15kW3.Power of servo motor (X

and Y axes):2×2kW4.The compressed air force ×discharging quantity:

0.5MPa×0.1m3/min5.Overall dimension (length

× width ×height): 3100×2988×2720mm6 weight :

Approx.6500kg7.The motor of X and Y axes are world famous brand AC

servo motor. The main electric controlling components (PLC and CNC

orientation system, encoder and switch without touching), hydraulic

components, pneumatic valve (electromagnetic valve, overflow valve,

and unloading valve) and cylinder are all world famous

brand.8.Working environment:Working temperature: 0ºC~ 40ºCPower:

Three phase four wire systemAC Voltage: 380VFluctuation of voltage:

±10%Frequency: 50 HzOther productsProduct accessories displayClient

feedbackCompany informationOur company is specialized in different

kinds of products. We stick to the principle of quality first,

service first, continuous improvement and innovation to meet the

customers for the management and zero defect, zero complaints as

the quality objective. To perfect our service, we make our products

with good quality at the reasonable price. The main products are

high-speed railing molding equipment, U-shaped column forming

equipment, iron tower processing equipment, steel structure

processing equipment, sheet processing equipment, flange forming

equipment, flame cutting machine, plasma cutting machine, laser

cutting machine, hollow glass aluminum spacer Production line,

hollow glass warm edge strip production line, furniture production

line, CNC engraving machine, hollow aluminum strip, hollow sealant,

etc. Its products are widely used in road and bridge construction,

construction steel structure, electric power tower, automobile

manufacturing, furniture manufacturing, decoration and decoration

industries.Product Packing & DeliveryFAQ01.Is the product packaged

in a wooden box or a cardboard box? Wooden box packaging

or bare02. Product production cycle?Each product is different,

generally 15-45 days03.A small number of products? To what

extent?Different products are different, some are 3-14 days or 7-30

days04.What is the production cycle of 04 customized products?The

delivery cycle of the product is different for each product.

Generally speaking, it is 20-45 days.05. What is the core

market?Indonesia, Malaysia, India, Vietnam, Thailand, Bangladesh,

Pakistan, Russia, Brazil and more than 40 countries and regions

around the world.06. What are our strengths?Shandong Zhongzixing

Intelligent Equipment Co., Ltd. is located in the high-tech zone of

Jinan City, China. It is mainly engaged in the development, sales,

installation, maintenance and import and export of smart equipment

and related accessories. The customer base is spread over more than

40 countries and regions around the world. The company has

experienced sales staff, technical support and after-sales team to

provide customers with quality, accurate products and professional,

efficient services.07. The main products?The main products are

high-speed railing molding equipment, U-shaped column forming

equipment, iron tower processing equipment, steel structure

processing equipment, sheet processing equipment, flange forming

equipment, flame cutting machine, plasma cutting machine, laser

cutting machine, hollow glass aluminum spacer Production line,

hollow glass warm edge strip production line, furniture production

line, CNC engraving machine, hollow aluminum strip, hollow sealant,

etc. Its products are widely used in road and bridge construction,

construction steel structure, electric power tower, automobile

manufacturing, furniture manufacturing, decoratio

Related products about CNC Plate Punching Drilling Machine Plate Steel Structure Plate Punching Line Steel Tower

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup