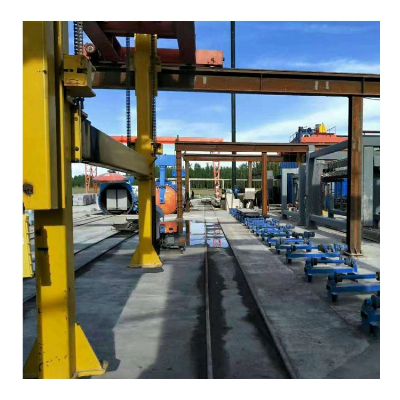

Product DescriptionAAC Production LineMain raw materials of AAC are

siliceous material (sand, fly ash and Silicon tailings) and Calcium

materials (lime and cement) mixed with foaming agent (aluminum

powder). It is the product of light porous silicate through the

following processes: batching, mixing, pouring, hardening, cutting,

autoclaving and curing etc. Because of large amount of

well-distributed tiny pores after foaming, it is named autoclaved

aerated concrete.Main Features1. Light weight, can reduce the

building's own weight and cost, and help improve the earthquake

resistance of buildings2. Good thermal insulation performance and

low thermal conductivity3. It has processability. It has the

same processability as wood. It can be sawed, planed, drilled and

nailed, which is conducive to construction and can be

operated on site.4. Strong pressure resistance5. Resistant to high

temperature, and the compressive strength of the aerated concrete

is slightly increased when the temperature is below

600 °C. When the temperature is around 600 °C, the compressive

strength is close to the compressive strength at

normal temperature, so The fire performance of aerated concrete for

building materials meets national first-class fire

protection standards. What machine

produce Gas block? as following:Main Process Flow of Gas

Block Production Line:1. Dose and match measured raw materials;2.

After distributing, feed raw material into pouring mixer to make

slurry.3. Through thoroughly mixing, the slurry is poured to mould;

,4. After pre-curing under a certain temperature and time, the

block would reach a certain hardness and prepare for cutting;5.

Tilting hoister would turn over 90 degrees of mould;6. Then open

the mould and separate it from block. And take the block with side

plate to the cutting cart;7. The horizontal cutting machine

cuts blocks from both sides.8. Then the vertical cutting;9.

After cutting, the block is hanged to curing carts with side plate

by semi-finished product hoister;10. Grouping the carts and put

them into autoclaves;11. Curing the blocks under certain

temperature and pressure;12. Carry the finished product out of

autoclave by the winch.13. The finished product hoister take the

finished product to finished blocks area;14. The side plate return

back through side plate roller;15. Side plate would be organized

with open mould for the next circle. Nine reason for

choice1.Famous band in shangdong.2.Famous trademark of

China.3.National key high-tech enterprise.4.National enterprise

abiding by contract and keeping good faith.5.Top ten influential

brand of China brick and the tile industry.6.First place in

productionand sales of brick machine and the tile making machine in

China.7.After-sale services throughout the country.8.ISO quality

system certificate enterprise.9.Supporting institution of Shandong

machinery institute. Product ParametersAAC block

introduction 1. Gas Ball Mill: grinding sand to

slurry

TypeDiameterLengthProductivityFeeeding

sizePower(KW)Φ1200x4500mm1200mm4500mm3-4t/h≤20mm55KWΦ1500x5700mm1200mm5700mm6-8t/h≤20mm130KWΦ1830x7000mm1830mm7000mm8-17t/h≤20mm245KWΦ2200x9000mm2200mm9000mm12-70t/h≤20mm380KW2. Gas Slurry

Pouring Mixer: To mix the standard sand ,slurry,lime,cement

and aluminium paste into balance after measuring Mixer

typeMotor powerMixer drum volumeBlade diameterBlade speedDiversion

drum type30kwV=3.6m3Φ560mm560r/minDiversion drum

type37kwV=4.5m3Φ630mm560r/min 3. Gas

block Mould: storage sand slurry to curingSize of

(mm)Size of body(Peeling-off size)Maximum overall

sizeLength(mm)Width(mm)Heigth(mm)Length(mm)Width(mm)Heigth(mm)4200x1200x600420012006004720173510784800x1200x600480012006005320173510786000x1200x60060001200600655017501085

4. Cutting machinea: Horizatal cutting machineSizeMin spacing

of wiresRange of swing(mm)Diameter of cutting wire(mm)Overall

sizeLength(mm)Width(mm)Height(mm)4.2x1.2x0.6m10mm7.5Φ0.6-Φ1.05200320035604.8x1.2x0.6m10mm7.5Φ0.6-Φ1.05900320035606.0x1.2x0.6m10mm7.5Φ0.6-Φ1.0720032003560

b: Vertical cutting machineSizeMin spacing of wiresDiameter of

cutting wires(mm)Overall size(mm)diameter of wires(mm)For side

trimming(mm)Length(mm)Width(mm)Height(mm)4.2x1.2x0.6m5mmΦ0.6-Φ0.8Φ0.85500286025004.8x1.2x0.6m5mmΦ0.6-Φ0.8Φ0.85500286025006.0x1.2x0.6m5mmΦ0.6-Φ0.8Φ0.8650028602500

5. Gas block Hoist: hoist block mould and

groupingsizeLifting capacity(T)Moving speed(m/min)Lifting

stoke(mm)Overal

sizeLength(mm)Width(mm)Height(mm)4.2x1.2m10t10-40m/min1350-17007700270028504.8x1.2m10t10-40m/min1350-17008300270028506.0x1.2m15t10-40m/min1350-17001050027002850

6. Gas block AutoclaveAutoclave Size(m)Autoclave

Volume(m3)Mould size(m)Mould volume(m3)Mould QTY /

AutoclaveΦ2.0x3197.34.2x1.2x0.63.02414Φ2.0x26.583.24.2x1.2x0.63.02412Φ2.68x31174.84.8x1.5x0.64.3218Φ2.68x32180.46.0x1.2x0.64.3215Φ2.85x32204.16.0x1.5x0.65.415Manufacturing

ProcessRaw material dealingPut the fly ash or sand into the ball

mill to mill via the conveyor belt, after milling, put the slur

Related products about AAC Block Machine Plant Production Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup