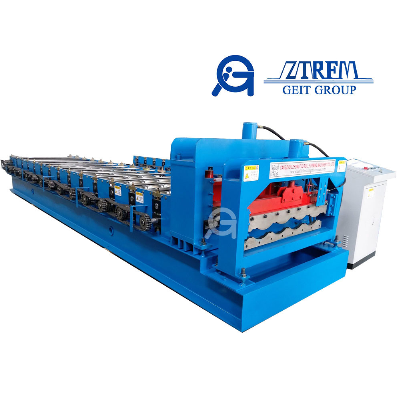

China Factory Lowest Price Steel Glazed Tile Roofing Sheet Roll

Forming MachineProduct Description This is the equipment that

mainly produces glazed tile. It is very common in our daily

life. Such as villa roof and tourist scenic Area

Architecture. Everything has its two sides,of course it

does. Its advantages are more three dimensional and beautiful

. so its disadvantages are hard to installation and high

price.Equipment

List

QTY TYPE Decoiler

system1Manual /hydraulicFeeding Inlet1Has manual broach Main

roll forming system1Integral /split step-formed

system1Electric /hyraulicshearing cut system1Electric /hydraulicPLC

control system1IntelligentReceving table1Simple manual

table/Automatic stackerAll of these systems can be custmized as

customer's request.Detailed

Photos A Decoiler

System Type manual hydraulicLoading

coil

width 1250/1450mm 1250/1450mm Bearing 5t 5t/10t ID

of

coil 450-550mm 450-550mm Note standard configurationwhether

to bring

car B Feeding

Inlet The Main

Parts Function a.two

rows of rubber steel b.two sides of chains c.manual

cut a protect material b.make it smooth c.

save material high efficiency feed Each

section can be customized c

Framework Stucture Guide

pillar/ arch/ Middle plate Be made of rods

roll shaft raking flying lifting

eyes lifting

holes rollers

spacer blocksOur advantages a. Thicker

wall b. more stable

framework Note Gearbox

drive more fluentEach section is

customized D Step-formed

system Before the shearing systemhas a

step-formed system. it can be electrical or

hydraulically. E shearing

Cuting type electric

cut hydraulic cut Drive

mode electric motor hydraulic

station Stucture channel

steel guide pillar channel

steel guide

pillar Apply totoo hot and too

cold areas any areaF receiving

table Type simple

manual

table Automatic stacker Lengthusually

3metres long any length can be

custmized Advantagesave space low

cost high-speed save time

and labour Disadvantage waste time and

labour high cost waste

space FIow Of Products 1 Decoiler 2

Feeding inlet 3 Main roll forming

system 4 pressing device 5 cutting device

6 PLC control system 7 Hydraulic station 8

Receving table Product Parameters Weight of main

part about 10 tons (as actual situation

) Drive mode chain/

gear / gearbox mode Material of

rollers 45#steel / ball bearing

steel Number of rollers 20

rollers or more(as actual situation) Hydraulic motor

power 3 4 5 kw(as actual

situation) Forming

way Integral /split forming

Motor power 9.5kw PLC system touch

screen/intelligent/international brandColour of machineany

colour(as customer's requirment) CertificationsCompany

Profile GENERAL INDUSTRY TECH

Developing Co,Ltd (GEIT GROUP) is a designing,

engineering and manufacturing company, based on many years

experience in metallurgy industry field. We have our own factory

in Botou-Heibei, which is a factory that

committed to designing and manufacturing of different types cold

roll forming machines. GEIT GROUP is a professional

manufacturer and exporter who is concerned with the design,

development and production of cold roll forming

machines. contact us

If you need,please mail me /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about China Factory Lowest Price Steel Glazed Tile Roofing Sheet Roll Forming Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup