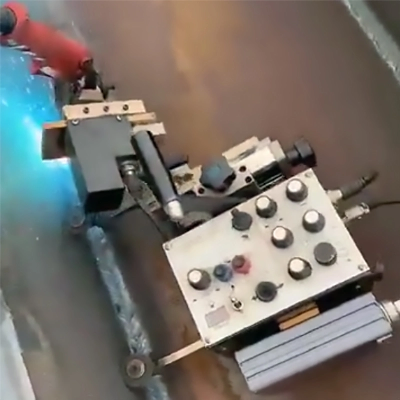

Portable Beam Welding MachineProduct DescriptionWJ-III swing

beam welding machine is widely used in ships, bridges, locomotives,

steel structure, petrochemical industry and other industries,

suitable for a variety of welding structures, such as:

reinforcement plate, rib plate, cross parts of the welding, box

beam welding, etc.. Product features1, WJ-III is swing automatic

welding device, one welding can get a wider weld.2, Swing speed,

swing range, center position and left and right residence time can

be adjusted, suitable for variousspecifications of the weld.3,

Equipped with magnetic handle, easy installation and center

alignment.4, An induction stop switch is installed, which can

automatically stop working when welded to the end of the workpiece,

so that one person can operate multiple devices.5, Small size,

light weight, easy to install and move, unskilled workers can also

carry out welding.6, Permanent magnet is installed to avoid welding

line disconnection during welding.7, The control device can be

disassembled and used as a remote control. It has magnetic

properties and can be placed on various workpieces. It is very

convenient to use.Product ParametersItemsParameterNoteTractor Power

supply AC 220V Size 240×330×310 mm W×L×H Weight 12 Kg Including

swinger Moving mode Four-wheel drive Rubber-wheel Walking speed

0∼880mm/min Control Swing motor DC24V 18RPM Adjustable range of

welding gun Up and down Before and after 85mm Operating Angle

adjustment range 360° Carry out Angle adjustment range 0° Operating

function Swing mode Swing speed 0-10RPM(Show with scale)

Swing scope 0-±10°(Show with scale) Left and right residence time

adjustment 0-2S(Show with scale) Central range of movement 0-±8°

Inching wire feeding Walking starts/stops Welding current/voltage

control Choice of walking direction Walking speed regulation

0∼1000mm/min(Show with scale) Welding/non-welding options Major

ComponentsComponents: welding gun swing device, slider, welding gun

handle, control box, control panel and other accessories: 1, Swing

device: used to drive the welding gun for pendulum swing welding2.

Driving part: the driving device of the trolley is composed of four

magnetic wheels, helical gears, chains and sprockets 3,

Slider part: used to adjust the position of the welding gun, you

can fine-tune the position before and after when welding. 4,

welding gun fixture: welding gun clamping device, it can adjust the

Angle of the welding gun. 5, Guide wheel: device that guides

the trolley along the welding line 6, Magnetic handle: For

easy movement and installation, magnetic handle is installed

7, control box: All movements of the tractor can be adjusted. For

details, refer to the operation method of the control panel.

8, Stop switch: When welded to the end of the workpiece can produce

induction to stop the carriage workControl Panel Introduction 1,

Knob for adjusting current and voltage: Turn the knob clockwise to

increase the value (The tractor has two power plugs of 3P and 8P,

when using 3P plug, the current and voltage adjustment knob is

invalid, and then the current and voltage of the wire feeder must

be adjusted; Current and voltage control knob is effective when

using 8P plug) 2, Selection knob for welding/non-welding:

the knob must be in the welding position to weld 3, Point

feed: manual wire feed device 4, Walking switch: control the

car walking and stopping, if the "welding/non-welding" switch is

placed in the "non-welding" position, open the walking switch, the

tractor only walking without welding 5, Walking speed

adjustment: the adjusting knob of tractor walking speed. It is

recommended to adjust the tractor walking speed after turning on

the walking switch 6, Choice of walking direction: choose to

walk left or right 7, Power switch and indicator light: the

indicator light is on after the power is energized 8, Swing

control part: it can adjust swing speed, swing range, left and

right stay time, center position and swing modeDetailed

Photos Company Profile Wincoo Engineering Co., Ltd (WINCOO) is

engaged in bringing the most suitable solutions/equipments for

client, fabricators, EPC/C companies on pipe fabrication, tank

construction, pipeline construction,industrial production lines,

clean energy project and other industrial field. Our Services &

Strength We have ability of providing workable solutions to support

clients to be awarded with shorter project execution time, fewer

man-hour cost and higher efficiency construction/fabrication method

and better quality during phase of project bidding. Based

client's facility/site space availability, we are able to

study/design and present matched configurations on project

schedule, quality, cost and productivity to guarantee production

pace is accordance with project requirement. To support

project execution, we are always ready to work as fireman to give

prompt supply on project materials from different consumab

Related products about Portable Beam Welding Machine for Steel Structure Production Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup