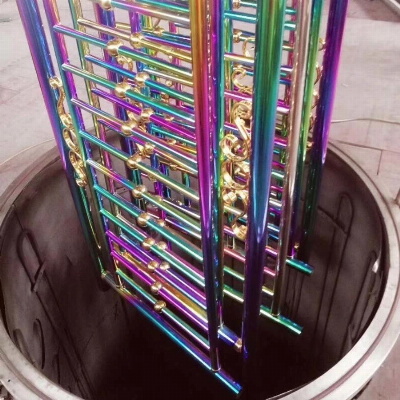

Stainless steel furniture table PVD ion coating machine The

series of equipment is designed for stainless steel sheet and pipe,

stainless steel parts to get a decorative coating by ion

plating technique, the ion plating layer has a real metal

texture, which is much different from chemical coating.We can make

machine Diameter from 800mm until 3500mm, height from 800mm until

7500mm, it suitable for coating all kinds of stainless steel sheet,

stainless steel pipe, and stainless steel parts and furniture

including, chair, table, handrail, display showcase, door handle,

door frame,advertising board, tableware, flatware, utensil

etc.Stainless steel sheets size(2 pieces per cycle,3 pieces per

cycle,4 pieces per cycle,6 Pieces per cycle)size: 4" x 8"

(1219mm x 2438mm) size: 4" x 10" (1219mm

x 3048mm) size: 5" x 10" (1523mm

x 3048mm) size (1500mm*4000mm) or Longer.Stainless

steel tubes:3-6 Meters Long, Diameter upto 127mm.We have installed

this machine in Korea,Thailand,Indonesia, German,Austrialia India

U.A.E.,Malaysia,Turkey,Iran, Egypt and other countries, we can

provide turnkey project for customers,including stainless steel

cutting,slitting,8k mirror,No.4.hairline,etching,PVD and plastic

lamintor line.Middle type:Vertical type:Features:The machine can

get all kinds of colors on stainless steel products, inluding

golden, rose gold, bronze, antique-bronze,coffee, blue, purple,

black etc. With three sets of large power vacuum pumping

systems, high pumping speed, short cycle time; With 34-56 pieces of

round arc targets, they are installed reasonable, at the same time,

equipment is equipped with pulsed bias system, which make the

adhesion of coating strong, color of coating uniform.Touch screen

+ PLC control achieved full automatic of equipment, manual and

auto can be switched any time, which make machine reliable and easy

operation.Color series:Imitation gold series: TiN, ZrN, TiN+Au,

ZrN+AuRose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au,

CuSilver white series: CrN, CrSiN, Zr (micro N)Grey series: Ti,

stainless steel (S.S), (S.S) NCoffee color series: TiCN, TiAlCN,

ZrCBlue series: TiO, CrO, TiALNBlack Series: TiC, TiC+iC, TiCN,

TiAlN, TiAlCN, Ti (C,O) and

DLC Model(customerize)HCCA-1215HCCA-1818HCCA-2236HCCA-2545HCCA-2270DimensionD1250*H1500mmD1800*H1800mmD2200*H3600mmD2500*H4500mmD2200*L7000mmLoading

ability1000*1300mm MAX1500*1500mm MAXSheet:1250*2500mm 4

pieces/BatchSheet:1250*2500mm 6

pieces/BatchSheet:1250*2500mm 10 pieces/BatchMachine

SizeL5*W5*H2ML6*W6*H2.5ML6*W8*H11.5ML8*W8*H12.5ML20*W8*H2.5MPower

sourceElectric-arc power, Filament power, Pulsed bias

power supplyProcess gas controlMass flowmeter + Electromagnetic

ceramic valveVacuum chamberstructure Vertical top opening door

or Horizontal open front door, pump system postposition, double

water cooling Vacuum systemDiffusion pump +Roots pump

+Mechanical pump(5.0*10-4Pa)Workpiece baking temperatureNormal

temperature to 350 centi-degree PID control, radiation

heating.Workpiece motion modePublic rotation Frequency control:

0-20 rotation per minuteMeasure modeNumber display composite vacuum

gauge: from atmosphere to 1.0*10-5PaControl

modeManual/Automatic/PC/PLC + HMI/PC four choice of control

mode RemarkWe can design the dimension of the equipment

according to customer's special technique

requirement.Application:Company Information:Factory

workshop:Certificate:Delivery:Clients:Why Choose HCVAC system?Over

3000 plants installed worldwideQuick cycle timesHigh production

capability with low energy consumptionMore up time due to ease of

loading/unloading and low maintenanceHigh productivity with only a

single operatorSteel process chambers, built to

lastEco-friendlySpace saving designPVD option available on all

plants1 year component warranty and 25 years minimum

guaranteed working lifeComplete global network of consulting,

engineering and renowned after sales service We developed a

complete after-sales system and effective service measures. Company

now owns a professional after-sales service team with more than ten

experienced engineers. HCVAC can help you to enter the

PVD coating easily by our vacuum coating machine and full range

service. We will provide with most suitable technology according to

your requirements. We will make the full set special coating

solution for each customer; combine the full set production

technics to meet your requirements, to ensure high efficiency of

production.ISO 9001 standard to ensure the quality can meet the

customer's requirements. Easy to implement:To many people

unfamiliar with the process, PVD coating technology seems

complicated. However, with the right investments and a good

support, it is easier than expected. HCVAC has developed

a turnkey coating process that makes a PVD coating centre

easy to implement. A complete coating process consists of

several steps: stripping (depending on the part's history);

pre-treatment; quality control; cleaning & drying;

fixturing & visual inspection; PVD coating; quality

control

Related products about Hcvac Stainless Steel Furniture Metal Vacuum PVD Coating Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup