PLASMA CUTTING CONSUMABLES: WHAT, WHY, AND HOW LONG DO THEY

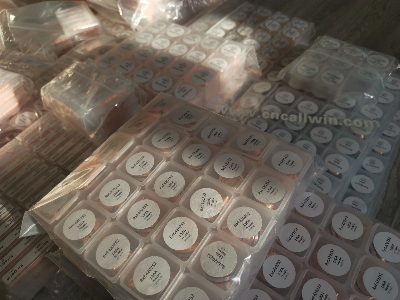

LAST? LARGE STOCK QTY;QUALITY GURANTEE;ONE-STOP

SERVICESUPPLYING ALL KINDS OF PLASMA CONSUMABLES AT FAST DELIVERY

TIMEPlasma cutters contain a number of consumable parts ,

which is unsurprising when you consider the very high temperatures

involved in producing and focussing an arc of plasma. Keeping on

top of the condition of these consumables is very important as it

will help to ensure a consistent high-quality cut, and reduce the

time involved in processing and refining your finished parts.WHAT

ARE PLASMA CUTTER CONSUMABLES?Plasma cutter consumables are a set

of components in your plasma cutter that gradually wear over time

until they need to be replaced: they have a life cycle. The

consumables are all found in the cutting torch itself, which is

where most of the energy is focussed, and keeping track of wear and

tear is a key part of maintaining an efficient machine that cuts

well and lasts a long time. Plasma cutting torch consumables

include: a swirl ring, electrode, nozzle, retaining cap, and shield

cap.NOZZLEThe nozzle focuses the plasma arc and the gas that

surrounds it to make a clean and precise cut. A nozzle with a

larger opening is used for gouging, while a nozzle with a smaller

opening is better able to direct the gas and so is used for fine,

detailed work.ELECTRODEThe electrode is a narrow piece of copper

containing hafnium (which is an excellent conductor of

electricity). Its job is to receive the electrical current from a

cathode block inside the torch to which it is connected, and to

focus the charge through its tip, which causes it to arc onto the

workpiece.RETAINING CAPThe retaining cap essentially holds all of

the consumable parts of the torch together. As temperatures at this

end of the machine are extremely high, it's not just the parts

creating and focussing the arc that are worn down; the component

holding them together also degrades over time.SHIELD CAPThe shield

is there to protect the torch and its other components from the

sparks and molten metal that result from the plasma cutting

process. It takes the brunt of the fallout so that wear to other

components is minimised as much as possible. NO.NAMEPart

NO.MODEL1nozzle220671powermax452shield cap2206733nozzle retaining

cap2207134electrode2206695swirl ring220670NO.NAMEPart

NO.MODEL1nozzle220671powermax45(handheld)2shield cap2206743nozzle

retaining cap2207134electrode2206695swirl ring220670NO.NAMEPart

NO.MODEL1nozzle220941powermax45xp2shield cap2208173outer retaining

cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220941powermax45xp(handheld)2shield cap2208183outer

retaining cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220819powermax652shield cap2208173nozzle retaining

cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220819powermax65(handheld)2shield cap2208183nozzle

retaining cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220816powermax852shield cap2208173nozzle retaining

cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220816powermax85(handheld)2shield cap2208183nozzle

retaining cap2208544electrode2208425swirl ring220857NO.NAMEPart

NO.MODEL1nozzle220990powermax1052shield cap2209933nozzle retaining

cap2208544electrode2208425swirl ring220994NO.NAMEPart

NO.MODEL1nozzle220990powermax105(handheld)2shield cap2209923nozzle

retaining cap2208544electrode2208425swirl ring220994NO.NAMEPart

NO.MODEL1nozzle220975powermax1252shield cap2209763nozzle retaining

cap2209774electrode2209715swirl ring220997NO.NAMEPart

NO.MODEL1nozzle220975powermax125(handheld)2shield cap4200003nozzle

retaining cap2209774electrode2209715swirl ring220997NO.NAMEPart

NO.MODEL1nozzle420044Maxpro2002shield cap4200453nozzle retaining

cap2209364electrode2209375swirl ring220488HOW LONG DO PLASMA CUTTER

CONSUMABLES LAST?Now that we've looked at the role each of these

consumable parts play, we'll move on to discuss how long these

elements last. The nozzle and the electrode will wear out more

quickly than other components, as they are most directly involved

with the creation and focussing of the cutting arc. You'll notice

nozzle wear primarily in the quality of the cut you are achieving.

As the nozzle wears, the hole in the tip gets larger, which makes

the plasma arc thicker and produces a wider cut (kerf) in your

workpiece. You will be able to see with a simple visual inspection

when the hole in the nozzle becomes too large and needs

replacing.CHECK WHICH PLASMA CONSUMABLES YOU NEEDIf you are looking

for plasma consumables, torches or torch assembly options it's

very important you order the correct parts based on your system,

material or amperage.Therefore we will provide you with an overview

of all current and legacy Hypertherm plasma cutting systems, so you

could see which option fits best your needs./* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a

Related products about Plasma Torch Accessories/Spare Parts Nozzles Electrodes Kaliburn Hypertherm Lincoln

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup