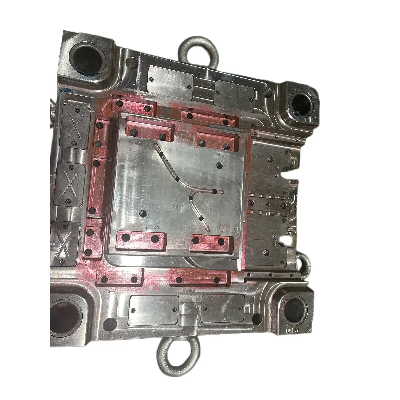

Product DescriptionAbout the use of plastic moulds for

automotive light guide bars and tips:1. The mold should be cleaned

before use to ensure that the surface of the mold is clean and free

of oil and impurities.2. During the mold processing, excessive

extrusion and vibration should be avoided to avoid affecting the

mold life and product quality.3. During mold processing, mold

parameters, such as temperature, pressure, speed, etc., should be

reasonably adjusted according to the specific material

characteristics and molding requirements to ensure product molding

quality.4. In the process of mold use, maintenance and repair

should be carried out regularly, such as cleaning, lubrication,

replacement of wearing parts, etc., in order to prolong the life of

the mold and ensure product quality.5. When storing the moulds,

avoid direct sunlight, humidity and high temperature environment to

avoid affecting the quality and life of the moulds.6. When using

the plastic mold for auto light guide bar, attention should be paid

to safety and correct operation to avoid accidents. At the same

time, the management and protection of the moulds should be

strengthened to ensure the quality and safety of the

moulds. The quality control and management of auto light guide

bar plastic mould manufacturing mainly includes the following

aspects:1. material control: select suitable plastic raw materials,

and inspect and test the raw materials to ensure that they meet the

relevant standards and requirements.2. Design control: Develop a

reasonable mold design plan, design according to customer

requirements and product characteristics, and conduct design review

and confirmation.3. Manufacturing control: Strictly implement the

manufacturing process and procedures to ensure the accuracy and

quality of the mold.4. Inspection control: Conduct comprehensive

inspection and testing of the molds, including dimensions,

appearance, durability, etc., to ensure that the molds meet the

relevant standards and requirements.5. Maintenance control: Regular

maintenance and upkeep of the moulds, timely repair and replacement

of damaged or aging parts to ensure long-term stable operation of

the moulds.In the process of manufacturing plastic molds for

automotive light guide bars, it is necessary to strictly control

the quality of each link to ensure the stability and reliability of

the products. At the same time, it is also necessary to establish a

perfect quality management system to trace and record each batch of

products to find and solve problems in time.The precision of the

light guide bar produced by the plastic mold of auto light guide

bar is high, which can meet the high requirements of the automobile

industry. Made of high-strength materials, they can withstand

long-term use and high-load production. Adopting advanced

production process and equipment, it can realize high efficiency

production and fast delivery. The materials used in the auto light

guide bar plastic mold meet the environmental protection standard,

and the products meet the national standard and industry standard,

which can ensure safe and reliable use. The materials used in the

auto light guide bar plastic moulds are low cost and the production

cost is also relatively low, which can provide customers with

cost-effective products.The plastic mold of auto light guide strip

is an indispensable part of auto interior, and with the continuous

development of auto industry, the demand of auto light guide strip

is also increasing. At the same time, with the transformation and

upgrading of the automobile industry, the trend of high-end,

intelligent and lightweight is also strengthening, which provides a

great opportunity for the development of plastic moulds for auto

light guide strip.In the future, the market prospect of auto light

guide bar plastic mold will continue to maintain stable growth. As

consumers' requirements for the quality of automobile interior

continue to improve, the design and manufacture of automobile light

guide strip will also be more refined and personalized. Therefore,

the auto light guide bar plastic mold manufacturing enterprises

need to continuously improve the technical level and product

quality to meet the market demand. At the same time, enterprises

also need to focus on innovation and research and development, to

develop new products more in line with market demand, in order to

maintain a competitive advantage.Dongguan Hongsheng Precision Mould

Manufacturing Factory is a professional enterprise engaged in mould

manufacturing. With advanced equipment and technology, we are

committed to providing customers with high quality mold

products.Our factory has an experienced R&D team, who are able

to design and manufacture various types of molds according to

customers' needs and requirements. Whether it is plastic molds,

metal molds or complex injection molds, we are able to provide

professional solutions. Dongguan Hongsheng Precision Mould

Manufacturing Factory also has

Related products about Auto Light Guide Strip Plastic Mould

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup