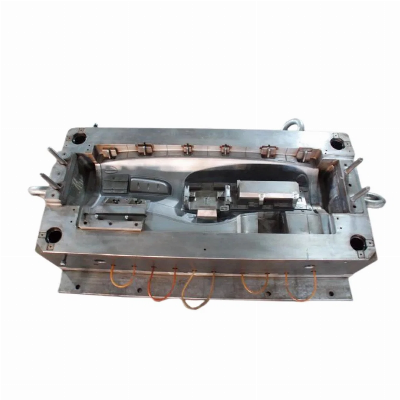

Product DescriptionThe design and manufacturing of plastic moulds

for automotive dashboard is a complex process that needs to go

through several stages, including from design to manufacturing,

mold trial, commissioning and final production process. The

following are the general steps of the design and manufacturing of

plastic moulds for automotive dashboard:1. Design stage: In the

design stage, the size and structure of the mold need to be

developed according to the model and the size of the instrument

panel, including the mold cavity, mold core, cooling water channel,

etc. The designer also needs to use CAD software to complete the 3D

model design of the mold, and conduct simulation analysis and

optimization to ensure the feasibility and production efficiency of

the mold.2. Manufacturing stage: In the manufacturing stage, each

part of the mold needs to be made according to the design drawings,

including mold frame, template, mold core, mold seat and so on. The

manufacturing process requires the use of advanced CNC machining

equipment and high-precision measuring equipment to ensure the

accuracy and quality of the mold.3. Mold trial stage: After the

mold manufacturing is completed, mold trial is needed to ensure the

quality and performance of the mold. In the process of mold trial,

all parts of the mold need to be adjusted, including mold opening

and closing force, injection pressure, temperature control, etc.,

to achieve the best production effect.4. Debugging stage: The

debugging stage is carried out after the mold trial stage, mainly

for fine adjustment and optimization of the mold so that efficient

and stable production efficiency can be maintained during the

production process.5. Production stage: After the completion of

mold trial and debugging, it can be officially put into production.

During the production process, regular maintenance and servicing of

the mold is needed to ensure the service life and production

efficiency of the mold. At the same time, it is also necessary to

make continuous optimization and improvement according to the

production situation in order to improve the production efficiency

and reduce the cost.In conclusion, the design and manufacturing of

plastic molds for automotive dashboards is a complex process that

requires professional design teams and advanced manufacturing

equipment. Only in the continuous optimization and improvement can

we achieve the best production effect and quality.Dongguan

Hongsheng Precision Mould Manufacturing Factory is a professional

enterprise engaged in mould manufacturing. With advanced equipment

and technology, we are committed to providing customers with high

quality mold products.Our factory has an experienced R&D team,

who are able to design and manufacture various types of molds

according to customers' needs and requirements. Whether it is

plastic molds, metal molds or complex injection molds, we are able

to provide professional solutions. Dongguan Hongsheng

Precision Mould Manufacturing Factory also has a plastic injection

molding workshop can achieve integrated production, from mold

design to injection molding one-stop service, improve production

efficiency and effectiveness. At the same time, the mold

manufacturing plant can be customized according to customer demand,

to provide customers with more personalized injection molding

products solutions.We focus on quality control and adopt strict

production processes and testing standards to ensure that each mold

meets high quality requirements. We have advanced processing

equipment and precise measuring tools to ensure the accuracy and

life of the molds.Our mold products are widely used in automobile

manufacturing, home appliance manufacturing, electronic product

manufacturing and other industries. Our customers are all over the

world, and they highly appraise our product quality and

service.Dongguan Hongsheng Precision Mould Manufacturing Factory

has a die-casting molding workshop which can realize the integrated

production of mold design, manufacturing and die-casting molding,

and improve the production efficiency and product quality. At the

same time, die-casting molding workshop is equipped with advanced

die-casting equipment and technology, can meet a variety of complex

shapes and high-precision requirements of product production. The

advantage of mold manufacturing factory with die-casting molding

workshop is to be able to provide customers with a full range of

mold manufacturing and die-casting molding services, to provide

high-quality product solutions.As a professional mold manufacturing

factory, we always take customers' needs as our guide and provide

the best solutions for them. We are committed to establishing

long-term relationships with our customers for mutual development

and progress.Please feel free to contact us if you have any demand

for mold manufacturing. We will be happy to provide you with high

quality products and services. Thanks!/* March 10, 2023 17:59:20

*/!function()

Related products about Auto Dashboard Plastic Mould Custom Production Plastic Injection Mould

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup