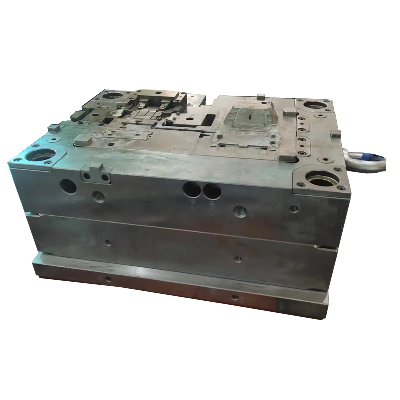

Product DescriptionProduct nameOEM Service Die Casting

Mold For Metal PartsMold shapingDie

Casting Mold baseLKM;HASCO;DME,etcMold materialNAK20,S136,P20.718H,738H,45#,etcMold cavitySingle or Multi Tolerance+/-0.02mmFinish Anodized,Polish,Silk-screen,Painting,etcSprue gateHot/cold runner;pin-point gate,etcDesign softwareUG,PROE,CAD,SOLIDWORK,etcProduct materialABS,PP,PE,POM,PMMA,etcMold life100k-500k shotsLead time25-45 daysTransportationBy sea, by air or by land as you requestPackageStandard or as you requestOEM/ODM AcceptableCertificateISO9001:

2015 Detailed Photos Other ProductsProject Management

Process1, Start from part design analysis. 2, Mold design

drawing and DFM report available so you can see how is the mold

going to be before mold making. 3, If product is complex,

moldflow report will be present as well. 4, In house mold

making shop ensure you mold quality under well control. 5,

Normally it takes 20-40 days to make mold, precise time depends on

part design.industrial, consumer, food processing, aviation,

seals/gaskets, lighting, packaging, filter, health care,

telecommunications, mechanical, water treatment, appliance,

recreation, lawn and garden, educational, oil and gas, government,

construction, plumbing, surveillance, pumps, marine, motors, gears,

RFID tags, electronics, and fasteners.Quality ControlHowe Mould

Quality Control1.Mould Material Q/Ca) mould steel checking

(hardness,flaw detection)b) mould spare parts checking

(hardness,size)2.Mould Making Process Q/Ca) design checking ( part

design,mould design,mould engineering drawing)b) mould size

checking (according to drawing)c) mould testing (check mould

working,sample) Company Profile Howe is a company

specializing in the design and manufacture of

high-quality plastic injection molds and injection molded

parts for the international market and Have been engaged in the

manufacturing sector since our inception.Is an OEM/ODM

factory, customized your products to meet your needs is our

advantage, We are managed by a group of professionals with

many years of experience in mold design, molding technology and

Quality control. We have developed an excellent understanding of

the technical and quality requirements needed. We build tools to

fit your expectations and match your quality standards.Our team of

CAD designers will ensure that your imagination is incorporated

into the actual product! If you want to create prototype or

mass-produce in a very specific project, we can help you

achieve your vision!Our products include :1. Custom Plastic

Injection Parts2. Multi-cavity plastic parts3. High Precision

Molds4. Insert & over molding5. Double Shot Mold(2K

mold)6. Unscrewing Molding7. Gas-assisted Molding8. Die Casting

Molding9. Prototype plastic parts and Low cycle plastic parts

molding10. Gas Assist molding11. Elastomeric molding12. IML

& IMD part production13. Thin wall plastic molding14. High

temperature moldingOur Advantages1. We are a manufacturer

specialized in OEM injection plastic parts from design to rapid

prototype to mold

to mass production for more

than 10 years. 2. Long term cooperation with some

Top Brand Auto Industry, such as Volvo. 3. We can assemble a

complicated products. Providing samples with important dimensions

and customizing inspection report material certification to

customers for validation and verification. 4. Equipment

includes CNC, EDM, grinding machine, injection machine (from 45ton

to 1000ton), we can supply high precision and

complex injection molds and products . 5. We offer unique

solutions to your products at a competitive price and best

service. 6. Strict quality control. The factory has the most

advanced testing equipment to ensure the precision of the

mold. 7. Your products will enter the supermarket, we

can design a package for you.8. Quick mold making and on-time

delivery. 9. We accept small order quantity, look

forward to receiving your inquiry.10. Excellent R&D

teams, Professional technicians and rich experienced

workers 11. Providing good After-sale service, if the products

have any quality problems, we will take charge of

it. Business PartnerWe have more than 12 years

experience in making plastic mold & die casting mold.Our mold have

TUV,SGS & ISO9001 Certification.If you have any demand on our

products, contact me free./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about OEM Service Die Casting Mold for Metal Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup