Clear PET corrugated wave roofing tile sheet manufacturing machine1

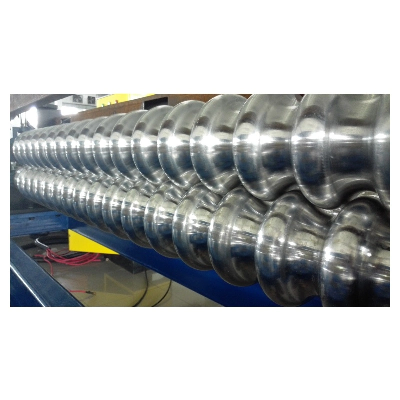

This line consists of single screw extruder, hanger-style flat die,

size forming mould, high--efficiency, vacuum pump, hauling--off

unit, pneumatic cutter and other auxiliary equipments.2 The

corrugated sheet extrusion line consists of single screw extruder,

corrugation forming machine, drawing machine, cutting machine and

so on. Such as is mainly used for producing colorful, weather able

and fire--resistant corrugated sheet which is used in architecture,

if changing some components, the line can also produce hollow

section sheet. Stable plasticizing, compact structure, highly

integrated automatic system, easily operation are the main

characteristic of the line, it is really the ideal machinery for

corrugated sheet production.3 Unique features: Bright colors, easy

to cut, handy, fire proofing and anti-corrosion4 Advantage;

1 excellent corrosion resistance 2. Weather resistance 3. High

effective 4. Durable in use5 Application: Workshop, storage,

garage, terminal market, gallery, clapboard, canopy and on.1)

Construction of sunroof in building, halls, shopping centers,

stadiums, public palces, etc2)Entertainment and public

facilities.3)Rain shield of bus stations, garages, pergolas,

corridors.4)Transparent shields for security forces in nursery

schools, airport, factories.5)Skylight of mordern agriculture and

aquacultures, indoorpools.6)Sign board for ads, light box and

exhibition services.7)Ceilings partition walls and exhibition

stands partition in office and residence.PET clear corrugated wave

roofing sheet extrusion machine other features:PET corrugated

roofing sheet is instead of tranditional PVC corrugated roofing

sheet. Machine is parallel twin screw extruder, raw material is PET

bottle flakes, no need crystallization system. It has more features

than PVC.1.High transparent, good for sun light.2.No bad smell,

fresh air condition3. Raw material cheaper than PVC4. Sheet

production is very simple, no dust pollution5. Sheet production

output is 1.5 times more than PVC6. PET machine no need to do screw

regular cleaning.(PVC need.)Right now many foreign countries have

a lot of waste PET bottles, people can not find a good

way to recycle them. Based on many years PET sheet extrusion and PP

PC PVC corrugated roofing sheet extrusion experience, we made PET

corrugated roofing sheet extrusion machine successfully.Our machine

feed with PET bottle flakes which is very cheap in the market.This

is a good project for customer.PET corrugated roofing sheet

parameters:Sheet width: 800-1000mm (or customized)Thickness:

0.5-2mm (or customized)Output capacity: 200-400kgs/hrIf you want to

know more details, pls contact me.Other machines:PET flat clear

sheet machinePP PVC PC flat sheet machinePP PVC PC corrugated

roofing sheet machinePET corrugated roofing sheet machine

details:PET corrugated roofing sheet application:Machine

shipment:YAOAN company plant view:Packaging and

shipping PACKAGINGplastic film + stretch film

+ wooden case + drying agent.DELIVERYAbout 120 days (all

new parts)SHIPPINGWe place and fix the machines well into container

and check carefully before closing the container so as to ensure

everything is ok for the shipment. (Use steel wire to fix machine

and drying agent).We care each and every point so that our clients

could receive the machines in perfect situation.What is our service

system?PRE-SALEa. Detailed machine introduction;b. Suggest suitable

turnkey solution as per clients requirements; c. Provide test

production for reference; IN PRODUCTIONa. Supply layout

drawing to clients for preparation; b. Suggest suitable

building project for pipelines, electric wiring, air pipes, cooling

cycle water etc; c. Keep the clients be informed of the

production status;AFTER SALEa. Send engineers to overseas for

installation ,commissioning and training;b. Supply extruding

products' material formula, recommend excellent supplier of the raw

material per clients' requests; c. Offer help if any need from

clients like spare parts need etc; d. Supply necessary

technical support at request;Why choose YAOAN MACHINERY? 1.

Profession: YAOAN only make plastic extruder since 1980s, extensive

experience and professional team ensure our leading position in

plastic extruder industry.2. Quality: The quality of products is

footstone of enterprise's constant development, always endeavoring

to do still better, quality comes first, developing

& innovative is our responsibilities;3. Delivery: We

optimize factory management, and improve production flow so as to

shorten production period for you in biggest extent;4. Cost

control: We do best to lower down production cost by our inner

management improvement, so as to ensure that our products are

competitive enough in market, and to realize higher

performance-price ratio of our products. FAQQ1: What is the

guarantee of the machine? A1: The guarantee period of our

machine is 12 months after the machine is installed well in bu

Related products about Clear Pet Corrugated Wave Roofing Tile Sheet Manufacturing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup