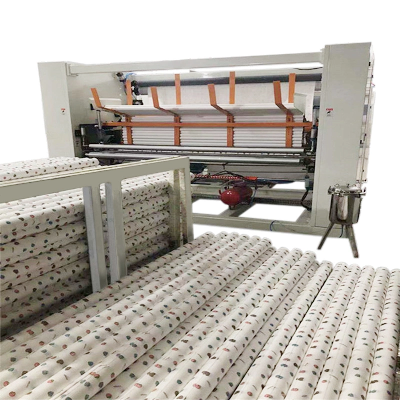

Equipment Introduction1. Adopt PLC programmable controller,

separate motor drive, tension control adjustment is adjusted on the

operating screen.2. Man-machine conversation, easy operation with

high production efficiency. Machine stop when raw paper

broke.3. Equipment production process: Two jumbo roll stands

(Pneumatic lifting raw paper)---One group of Embossing and

glue lamination unit ---one set of steel to steel embossed( for

produce lazy rag with embossing heating)----pressing and

conveying device----perforating unit ----rewinding unit

---Tail trimming and gluing(including auto discharge)Main technical

parameter production speed:Stable production speed for

producing glue lamination : 150-200m/min (depends on the

rewinding diameter)Stable production speed for producing lazy rag:

60-80 m/min Finished roll diameter: 100-130 mmPerforation distance:

100-240 mmJumbo roll paper width:2170 mm (According to customer

requirements,from 1500-2850 mm)Jumbo roll paper diameter: 1200

mmRaw paper weight (gsm): 13 g/m2-40 g/m2Machine weight: about

8.2 tonsMachine power : about 27.1 kw +heating 16 kw

(380V 50HZ)Machine Overall size(L*W*H) :7000*3580*2150

(mm)About UsQuanzhou Huaxun Machinery Making Co., Ltd.,

established in 2009, is a manufacturer of household paper

processing equipment and integrating design, R&D,

manufacturing and sales. The products are mainly including

kitchen towel toilet roll rewinding series, facial tissue

making machine series, napkin processing machine series,

slitting machine series, core winding machine series,

Non-wevens processing machine series, and other relating auxiliary

equipment. The products have passed the international ISO:

9001-2000 quality system certification and CE certification, and

provide good services for the design and production of equipment

suitable for the product market for global household paper

enterprises. FAQ1.How to start an order with us

?1. Inquiry -Email Wechat/whatapp replying within 12

hours.2. Solution offer - Best quotation based on

your product, production capacity ,invest plan ,budget

ect.3. Customized -Customized according

your practical requirement.4. Preparation before placing

order -Share the machine space ,air ,power ,electric with

you to ensure fit with your factory space.5. Confirm the

order -With the advanced payment for starting machine

production .2.How to check the quality of the machine you ordered

and the guarantee ?-Each part is marked with the source code of the

supplier1. Quality control -Each part is marked with the

source code of the supplier.12 months Warranty,We would express the

free replacement parts during the warranty date.(exclude wearing

parts). The express cost of parts should be paid by the buyer.

After one year, our company will carry on the tracking of

technology and quality.2. Delivery- Packing according to

international shipping FOB.3.How about the Installation and

training when the machine arrive your factory

?1. Installation -Engineer Schedule confirmed 7 days

before machinery arrival ,7-10days for installation depend on the

machine operation difficulty .2. Training The seller will

send technicians to the buyer's factory to install and adjust the

machine. The seller is responsible for the round-trip air ticket

wages, and the buyer pays the technicians' accommodation (board and

lodging) and transportation (bus fare, etc.). (If the technician is

required to go there for the second time, the cost shall be borne

by the buyer). The buyer should prepare electricity, gas source,

raw materials, etc. before the arrival of the

technician.3. Cost of Installation & Training :You should

cover round-trip air ticket wages, and the buyer pays the

technicians' accommodation (board and lodging) and transportation

(bus fare, etc.). You should prepare electricity, gas source,

raw materials, etc. before the arrival of the technician..4.How to

build a long-term partnership between us ?Feedback - Your

sincere feedback is the most effective reference for the continuous

improvement of our service.Packing and shippingWooden pallet/

Plastic film/ ContainerShipping /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Double Used Lazy Lag and Toilet Paper Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup