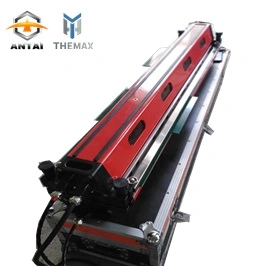

600mm Portable PVC/PU Belt Air Cooling Press

VulcaniserACP1200 Air cooled press has all componets

integrated into the tool,allowing a user to plug it simply into

electricity and it's ready for use.Fast and Portable Splicing,can

be bring to anywhere easily.Specifications:•ANTAI ACP series

air cooled press,have different models from 300mm to 2100mm.•Used

for PVC/PU/PVK Belt and thermoplastic belt materials etc.•Portable

splice press,light weight and with flight case as standard

packing,easily removed to anywhere for on-site joint work.•Fast

Splicing:Heating and cooling time:no more than 12mins.•All-in-one

design:Integrated air cooling system and also air compressor

inside.To ensure that belt is quickly cooled down and auto press

on,without water pump or additional air compressor.The air

compressor made in Germany.•Reliable and automatic temperature

control with time controlling(in one meter,also you can sent by

yourself).High quality Euro thermistor.The temperature controller

from Eurothern,made in UK.•Air pressure controller (set the air

pressure and display the current pressure),High quality SMC

Controller.Specification list• 300 mm effective (12") • 600 mm

effective (24") • 900 mm effective (36") • 1200 mm

effective (48") • 1500 mm effective (60") presses

function on different voltagesSpecification

listModel30060090012001500Effective length305mm / 12″610mm /

24″914mm / 36″1219 mm / 48″1524 mm / 60″Effective width120mm /

4.7″120mm / 4.7″120mm / 4.7″120 mm / 4.7″120 mm / 4.7″Weight lower

part11.5 kg18kg23kg28.5 kg32 kgWeight upper part12kg13kg18kg25.5

kg30 kgTotal weight21kg30kg38kg54 kg62 kgOverall

height220mm225mm225mm225mm225mmMax. pressure2 Bar / 28 PSI2 Bar /

28 PSI2 Bar / 28 PSI2 Bar / 28 PSI2 Bar / 28 PSIMax. temperature200

ºC/390 ºF200 ºC/ 390 ºF200 ºC/ 390 ºF200 ºC/

390 ºF200 ºC/ 390 ºFPackaging list(L x W x

H)790x430x420mm1090x430x420mm1390x430x420mm1720*450*430mm2030*470*410mmGross

weight50 kg72 kg85kg104 kg127 kg Packaging & ShippingCompany

ProfileANTAI is the leading manufacturer of conveyor belt

vulcanizing equipment. ANTAI has been offering unique Sectional

Vulcanizing Systems that provide strong, long-lasting splices, for

over 27 years in china.The Unique and Innovative belt splicing

system designed to be portable and offer maximum versatility in

splicing all types and sizes of conveyor belting. It's intelligent,

modular design and vast array of unique operating features, can

handle all types of belt designs in every conveyor application.The

ZLJ series belt vulcanizing machine (hereinafter referred to as

vulcanizer) is an electrothermal type vulcanizing device used

for on-site splicing of conveyor belts. With the advantages of

advanced technology, compact structure and convenient usage, it's

used for the vulcanized jointing of the belts mixed with

canvas, nylon, steel cord, etc., and it's also suitable for the

flame retarded, corrosion proof and other special belts. The

application area of this kind of vulcanizer is very wide, it

can be used in metallurgy, mining, power plant, port and

wharf, building material factory, chemical factory and so

on.The Sectional vulcanizer offers equipment, which is portable and

easy to set-up and remove from the site. It has accurate control

and indication uniform temperature due to the unique element design

and uniform pressure over the entire splice area. Components in

this model are lightweight and easy to assemble.FAQ 1. What

does your factory do regarding quality control?We pay much more

importance to quality control from the very beginning to the end of

production. Every machine will be fully assembled and carefully

tested before shipment. 2. What's the machine quality

guarantee?Quality guarantee time is one year.We choose world famous

brand components to keep our machine in perfect working

condition. 3. Are you able to give installation and

commissioning overseas?How long time will it take?Yes, we can

supply overseas service and technical support but customer needs to

pay for the cost of the installation. Small machine usually takes

within 2~3 days. Big production line usually takes about 30

days. 4. How can I trust you to deliver the right machine as I

ordered?We will absolutely deliver a good quality machine as we

discussed and confirmed in the order. The core of our company

culture is innovation,quality,integrity and efficiency. Also we

have had many good cooperation with world famous rubber production

manufacturers. If you come to our factory, we can show the

user around us. 5. How can we go to your side? We are

located in Qingdao City, Shandong province, China. The name of

airport is Qingdao liuting airport. We will pick up you at the

airport. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 600mm Portable PVC/PU Belt Air Cooling Press Vulcaniser

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup