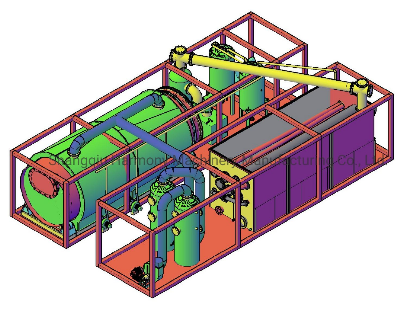

1.Tyre Recycling Pyrolysis Equiment Working Process1.Feed raw

materials:The raw material can be waste tire/waste plastic/waste

rubber. Always feed by the auto feeder. 2.Pyrolysis:Include a

reactor and catalyst room. Heat the reactor by

coal/wood/oil/natural gas.This part will produce high temperature

oil gas, the oil gas then flow into the next system.3.

Condensing:Oil gas come out from the reactor and catalyst chamber

then cooling down in this part.Condensing system include condenser

pipe, oil water separator, horizontal condenserand waste gas

condenser. This will make the oil yield to the maximum.4.Waste gas

recovery:This part mainly deal with the gas that cannot be

condensed. The whole process is verysteady and high efficiency.5.

Discharge:After finished oil produce, the temperature of reactor

can be cooled down, When thetemperature falls down to 40 degree

then carbon black can be discharged automaticallyby the way of

anticlockwise rotate the reactor. The carbon black will drop into

slag pooland then use screw conveyor to clean the slag pool. After

discharging the carbon black,we can discharge the steel wire. There

is steel wire hook in the auto-feeder, we only needput the steel

wire hook into the reactor, and start the motor, the steel wire can

be pulled outeasily, there is no need for workers to contact the

reactor, it is very convenient.2.About oil rate for different

material Oil yied/dayWaste tire/ rubberBig

tyres45%--50%Car tyres40%Bicycles and motorcycles

tyres30%--35%Waste plasticFishing net45%--50%Safety net ,

farm-oriented filmConwenient bags , weave bags40%Off cut of

recycled paper mill20%--30%3.Major partsloading plastic into

reactor heating reactor after heating , solid plastic converted to

oil gas oil gas go into oil-gas separator ,heavy oil deposit and go

to heavy oil tank, light oil gas go to cooling system after cooling

,light oil gas change to liquid oil and go into light oil tank

non-liquid oil gas will to water sealing tank, then back to

combustor burning to heat reactor as fuel smoke produced by heating

reactor will go to dedust system, after dedust system treatment ,

smoke change to white clean waster steam ,then go to sky through

chimney. 4.Technical ParameterNO.NameParameter1The raw

materials:waste tyres, plastic and oil sludge,rubber2Total

capacity:10t/day3The size of reactor2800*6000mm,4Average oil

productivity:tyre:40%-50%, plastic:60%-80%5Average carbon

productivity:30%-35%6Average steel productivity:10%-15%7Average

waste-gas productivity:5-8%8pyrolysis time8hours9Discharge

time3hours10Feeding time3hour11Cooling time3hours12.Delivery15

days13.Payment term30% Advance payment, balance paid before plant

loading14.Oversea

usersLebanon,Korea,Poland,Turkey,Mauritius,Brazil,Malaysia,

Indonesia,Vietnam,Philippine,Thailand,Pakistan,India15.InstallationEngineer

guiding installation for free,buyers offer round-ticketsand

accommodation16.Warranty period2 years warranty, lifetime

maintenance5. About usShangqiu Harmony Machinery

Manufacturing Co.,LTd. is a professional manufacturer engaged in

the research, development, production, sale and service of

Environmental machines, waste tire/rubber/plastic pyrolysis

equipment, waste oil distillation machines, etc. We have rich

experience(5 years experience) in making and installation. Dayi is

the top 10 enterprise in disposing waste rubber and plastic and has

been cooperated with one South Korea company to dispose waste

plastic . The company has gained rich experience and achievement in

processing waste solid. This project in dealing with city living

waste has been approved by South Korea government and the

continuous equipment has been under testing in Korea. The

production line of processing level 2 waste tyre with automatic

control has been under testing in Hong Kong. Our company is about

133400 square meter ,and the workshop is 58000 squremeter ,we have

lathes ,milling machines,grinding machines and planders , broaching

machines ,pucnhing machines,NC lathes,CNC miling machies,digital

control drill and other testing device.We have more than 100

workers including 3 high-class engineers,10 professors ,and 40

technicists.Our Machine have been sold to India, Malaysia,

Pakistan, Bangladesh, Lebanon, Mexico, Europe ETC. 6.About payment

and delivery30% TT advance payment ,balance paid by sight LC We

will delivery plant within 20days after getting deposit payment We

offer workers to customer site for guilding installtion and

training workers for free Reactor warranty is 5 years, whole set

plant warrant y is one year 7.Specification

choices:SpecificationCapacityRaw materialHeating materialWorking

time (hrs)Shipped byXHZT-2200-60005TonWaste

tyresCablesPlasticsRubberOil sludgeWood,coal ,oil,gas122*40HQXHZT

-2600-60008Ton151*40HQ+1*40FRXHZT

-2600-660010Ton181*40HQ+1*40FRXHZT

-2800-600010Ton181*40HQ+1*40FRXHZT

-2800-660012Ton201*40HQ+1*40FRXHZT -2800-660015tonMedical

waste 221*40HQ+1*40FRContiuous plant20TonOther

waste 243*40HQContiuous plant60Ton 245*40

Related products about 100% Installation Finished Befor Ex-Work 10 Tpd Tyre Recycling Pyrolysis System

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup