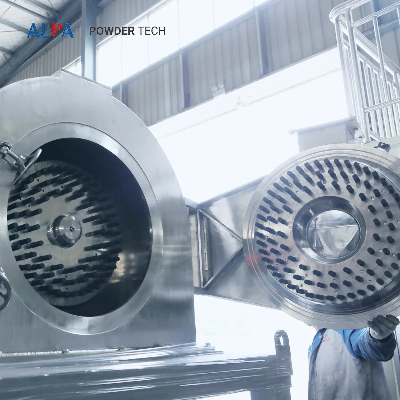

CUM-P Pin MillSingle Rotor / Multiple RotorWidely used in chemical,

inorganic salt, medicine, food, pigments, dyes, pesticides, battery

materials, minerals, refractory materials and other

industries.Features and Advantages* Available D50:10-45μm.* No

sieve, smooth discharge, high capacity and low operation cost.*

High line speed, finer particle size.* Compact structure and small

occupation. easy to disassemble and clean* Lower installation

power, wide application, high cost-performance.* Different

installation combinations, applicable to different process

requirements* Grinding is in closed system, low dust and noise,

clean and environmentally friendly production process.* PLC control

system, easy operation.* Single or double drive, if upgraded to

dual power, reaching 200m/s or more line speed, to obtain the

maximum grinding force* The motor can be connected with a belt to

increase the speed and break through the problem of high-speed

motors without the well-known motor brand.* Can be used in series

with multi-stage classifiers to produce products with multiple

sizes at one time.* Optional explosion-proof design, meet the

ultra-fine grinding processing requirements of flammable and

explosive oxidematerials* High-temperature, low-temperature,

normal-temperature, airtight cycle, Inert gas cycle designs are

available, for differentgrinding requirements of different

materials. Working PrincipleA pin mill(pin mill grinding,micro

pin mill,fine pin mill,pin mill grinding, pin mill Crush, pin mill

pulverizer,pin grindingequipment) is a mill machine that comminutes

materials by the action of pins that repeatedly move past each

other.Much like a kitchen blender, it breaks up substances through

repeated impact.The mill is a type of vertical shaft impactor mill

and consists of two rotating discs with pins embedded on one

face.The discs are arrayed parallel to each other so that the pins

of one disk face those of the other. The substance to be

homogenized is fed into the space between the disks and either one

or both disks are rotated at high speeds.Pin mills can be used on

both dry substances and liquid suspensions.Pin mills are commonly

use in the manufacture ofpharmaceuticals, as they can achieve

particle sizes as low as a few micrometers.The material is evenly

fed into the grinding chamber by the feeding system, strongly

impacted by the high-speed rotating disc.At the same time, it is

subjected to various comprehensive forces such as friction,

shearing and collision between the static disc and the ring gear to

grind material.The moving disc and static disc can be combined in

different structural forms according to nature of material to meet

the grinding requirements of different materials.ALPA is China's

largest pin mill manufacturer and supplier. We have an advanced

factory that offers unique processes and designs. Technical

ParametersParameter / Model1602603605006308001000Diameter of coarse

grinding disc (mm)1802703805806407501000Rotating speed of coarse

grinding disc (r/min)9000600046802480230021501800Linear speed of

coarse grinding disc (m/s)84.884.893.175.377.184.494.2Ground power

(kW)47.52237455575Dual power

(kW) 22+30 2x55 Diameter of micronized

grinding disc (mm)1602603605206307301000Micro powder type speed

(r/min)12000750055503850320028002050Linear speed of micro-powder

grinding disc (m/s)100.5102.1104.6104.8105.6107.0107.3Micro powder

type power (kW)47.52237557590Air volume

(m³/h)(max)3601000240032005700750010000Note: The production

capacity is closely related to the particle size, specific gravity,

hardness, moisture and other indicators of the raw materials. The

above is only for selection reference.Related Engineering

Cases Shandong ALPA Powder Technology Co.,

Ltd.(abbreviation: ALPA / Equity Code: 171033) THE WORLD'S

LEADING SUPPLIER OFULTRA-FINE POWDER SOLUTIONS ALPA is a

world-renowned supplier of powder processing systems, committed to

traditional powder industry development. For 20 years, focused on

the research and development of dry grinding, classification,

powder shaping, surface modification and provided systematic

solutions. We provide customized and international certified

products: Jet Mill, Air Classifying Mill, Classifier, Ball Mill and

Classifying production line, powder surface modification production

line, etc. WHO CHOOSE US 37 world top 500 companies, 89

Chinese top 500 companies, 169 national key laboratories and

engineering technology research centers have selected ALPA.More

than 3,000 customers have chosen us

Certification AuthorityALPA is one of the earliest

companies in the industry that passed the ISO9001 quality

management system authority certification. At the same time, ALPA

has free import and export rights, and has obtained CE

certification for export to the European Union and GOST

certification for export to Russia. The machine design used in the

medical industry fully meets the requirements of GMP c

Related products about Particle Size D50: 10-45um Impact Pin Mill for Chemical/Medicine/Battery Material

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup