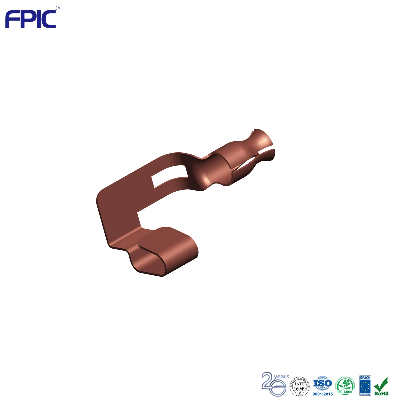

Precision Auto Bending Stamping

Parts Stainless Steel Stamping Parts

In Forman,you can find

various exiting connectors and also we can offer you the customized

products,not only the plastic injection services but also the metal

stamping(sheet metal) services.According to your requirement,our

team will offer you the most competitive solution and offer the

best performance.Product DescriptionWe have tooling workshop and

metal stamping workshop to ensure controling the product quality

in all the process . Metal stamping parts is one of our main

business, especially for automotive metal stamping

parts. Product Name Precision Auto Bending Stamping Parts

Stainless Steel Stamping PartsRaw MaterialCopper,Stainless Steel,

Phosphorous bronze,Aluminum Alloy....

CustomizedApplicationAutomotive Connector,Electrical

ConnectorColorWhite ,Black, Gray, CustomizedR&D Ability14

menbers weathy experience R&D team ,Design structure and Open

New moulds according to your requirementPackagePE bag/ Tray /tape&

Reel with lable in export standard CartonOur CapacityFull-Auto

Production Line for plastic injection,metal stamping and assembly

services,also the CCD inspection,Our Max. Stamping Machine Tons.200

Tons.Our Max Injection Machine Tons300 TonsOur Production Cycels21

working days for the new mould and within 7 working days for

exiting model(Depends on the QTY)Our

CertificateISO9001:2015;ISO14001:2015;IATF16949:2016Quality

Assurance100% CCD inspection and QC spot check per 2 hours.OEM

stamping spare Parts Company ProfileShenzhen Forman Precision

Industry Co.,Ltd has been committing to electronic component

manufacture since 1999 with strong R&D and Full-Auto production

capacity.Forman supply a range of USB connectors,Pin

Header,FPC,Wafer,Automotive Components and custom services.After 20

years development that Forman has passed ISO9001,ISO14000 and TS

16949 and become the member o f USB Associate. And we are proud of

our progress, since our goods are widely used in many international

brands and our quality is approved based on scientific TQM

system.FPIC insists on introducing advantaged facility to improve

our capacity from production and quality assurance,its in order to

add customer value and enhance our competitiveness. We warmly

welcome your enquiry,Forman will be your most suitable and

understand partner.Factory workshopProduction ProcessExiting

Products: Inquiry with your requirement/drawing - Offer you our

most suitable products / Modify the structure based on our exiting

model - Send the free sample - confirm the sample - Place the order

- Deposit - Start Production - Offer documents before shipment -

Arrange the remainder payment - DeliveryNew Products: Inquiry with

your drawing / requirement - Offer you our most competitive cost -

confirm the structure and mould order - Mould deposit - Finish the

sample and test - Sample delivery - Sample confirm - Arrange the

remainder mould cost - Place order - Offer related documents before

shipment - Arrange the remainder cost - DeliveryQuality

Assurance Certifications Honor From CustomerFAQQ: Are

you trading company or manufacturer?A: We are factory, so we can

provide competitive price for you.Q: What kind of products can you

provide?A: Our company (FPIC) can provide OEM/ODM spare parts. We

are an experienced OEM / ODM business, focusing on tooling and mass

production of Stamping parts, Injection-molded plastic parts and

Insert-molding components .Q: What's kinds of information you need

for a quote?A: In order to quote for you earlier, please provide us

the details together with your inquiry.1. 3D drawings (STEP, CAD,

SOLID Works, PROE, DXF and PDF)2. Material requirement (include

contact material and insulation material.)3. Surface treatment4.

Quantity or Consumption (per order/ per month/ annual)5. Any

special demands or requirements, such as packing, labels, delivery,

etc.Q: What shall we do if we do not have drawings?A: Please send

your sample to our factory, then we can copy or provide you better

solutions. Please send us pictures or drafts with dimensions

(Thickness, Length, Height, Width), CAD or 3D file will be made for

you if placed order.Q: What makes you different from others?A.1.

Our know-how R&D team with 14 member who all have rich

professional knowledge and experience about connectors2. Automated

production equipment and matched quality testing equipment.Q: Is it

possible to know how are my products going on without visiting your

company?A: We will offer a detailed production schedule and send

weekly reports with photos or videos which show the machining

progress.Q: Can I have a trial order or samples only for several

pieces?A: As the product is customized and need to be produced, we

will charge sample cost, but if the sample is not more expensive,

wewill refund the sample cost after you placed mass orders.THANKS

FOR YOUR PATIENT READING AND KINDLY CONTACT US FOR TIMELY

SERVICES. /* March 10, 2

Related products about Fpic Aluminum Sheet Metal Stamping Parts Car Accessories Stamped Metal Part

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup