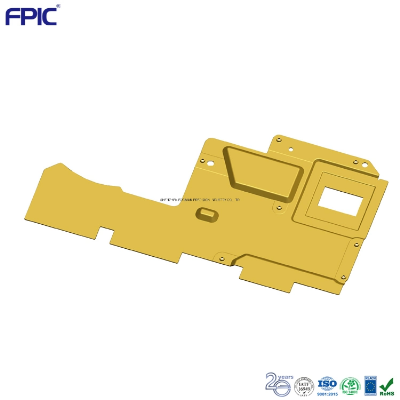

Sheet metal fabrication copper parts OEM stamping metal

accessories Forman is committed to optimize

factory strength, improve quality control systems, and enrich

R&D capacity to face greater challenges and meet different

requirements. By now, our products are widely applicable for

consumer electronics, the automotive industry, testing instruments,

and so on. Product DescriptionSpecificationOur CapacityFull-Auto

Production Line for plastic injection, metal stamping, and assembly

services, also the CCD inspection,Our Max. Stamping Machine

Tons.200 Tons.Our Max Injection Machine Tons300 TonsOur Production

Cycles21 working days for the new mold and within 7 working days

for exiting model(Depends on the QTY)Our

CertificateISO9001:2015;ISO14001:2015;IATF16949:2016Quality

Assurance100% CCD inspection and QC spot check per 2 hours.Stamping

Copper PartsForman offers precision metal stamping services for the

various electronic terminal, auto spare parts, and so on, its

possible for us to handle the material such as copper alloy,

aluminum alloy, stainless steel, etc.We have been specialized in

metal stamping since founded in 1999, we offer one-stop fabrication

services from mold design, mass production, surface treatment to

delivery. Now, there are 24 sets of high-speed automatic punch from

35 Ton to 110 Ton which includes Kyori Matte 4, Yamada. With over

20 years of strong development, our products are applied for

electronic connectors, automotive components, and other industries

that are mainly made of phosphorous bronze, brass, stainless steel,

Iron, and so on. Production Area Nowadays,

Forman has its own mold-making, plastic injection, metal stamping,

and components assembly workshops. Here we can design and make the

tooling for auto-injection and progressive stamping. Meanwhile,

develop and produce custom plastic injection parts, metal stamping

parts, different auto components, and connectors. In order to make

higher precision and quality products, we have imported various

precise equipment like Seibu and Sodick slow-feeding wire-cutting

equipment, Fanuc and Nissei injection facilities, Kyori and Yamada

punch. And the machines in our assembly workshop were designed and

installed by our team, which can automatically finish the assembly,

inspection, and package for stable quality and high

productivity.

Tooling Making Department

Metal Stamping Department

Plastic Injection Department

Auto-Assembly Department Quality Management

We clearly understand the quality importance for a company,

therefore, every aspect from product designing, producing, to

inspecting has been paid attention to. We verify the material

reliability in the designing stage, then control every process will

strictly comply with all quality systems for best quality in

production. Now, we can finish dimension measuring, hardness

testing, tensile strength testing, coat thickness measuring,

contact resistance testing, flame retardant testing, and various

environment testing in our own laboratory with many excellent brand

instruments, like Keyence, Nikon, Fischer, and so on.Quality

AssuranceCompany ProfileShenzhen Forman Precision Industry Co., Ltd

has become the global leading supplier in electronic components

since found in 1999, as our innovative design, strong production

competence, and strict quality management.Until 2018, Forman's

total investment has been over RMB50 Million, completely achieved

scientific automatic manufacture in plastic injection, metal

stamping, and assembly, and past ISO9001, ISO14001, and IATF16949

certification. Meanwhile, we are constantly introducing foreign

advanced equipment, technology, and company management experience,

insisting on developing and attracting multi-skill technology

talented people to establish a high efficiency, high-quality

production team.Forman is committed to optimize factory strength,

improve quality control systems, and enrich R&D capacity to

face greater challenges and meet different requirements. By now,

our products are widely applicable for consumer electronics, the

automotive industry, testing instruments, and so on. Quality

System CertificationCertifications By the

philosophy of "Focus on Customer, Contributor Based, and Always

Going All Out", Forman has established a long-term cooperation

relationship with many world-famous companies. There is no doubt

that the capability of quality controlling, super flexible

delivery, and continuous cost optimization can lead a long-term

development, we look forward to working together with you for

mutual development and benefits./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Sheet Metal Fabrication Copper Parts OEM Stamping Metal Accessories

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup