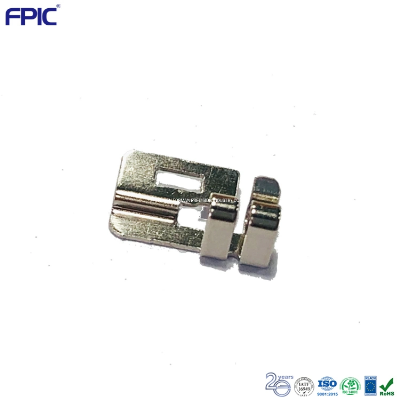

Good tolerance precise stamping electronic spare parts metal

hardware Forman has been specialized in

high-end electronic connectors, and OEM fabrication services for

automotive components, medical equipment parts, and custom

accessories based on injection, stamping, and assembly processes.

With over 20 years of healthy and strong development, Forman has

been the direct and indirect supplier for many world-famous

companies.Product DescriptionSpecificationOur CapacityGood

tolerance precise stamping electronic spare parts metal hardwareOur

Max. Stamping Machine Tons.110 Tons.Our Max Injection Machine

Tons180 TonsOur Production Cycles21 days for the new mold and

within 7 working days for the exiting model(Depends on the QTY)Our

CertificateISO9001:2015;ISO14001:2015;IATF16949:2016Quality

Assurance100% CCD inspection and QC spot check per 2 hours.Major

OEM productsMetal Spare PartsProduction Flow Exiting

Products:Inquiry with your requirement/drawing - Offer you our most

suitable products / Modify the structure based on our exiting model

- Send the free sample - confirm the sample - Place the order -

Deposit - Start Production - Offer documents before shipment -

Arrange the remainder payment - DeliveryNew Products:

Inquiry with your drawing/requirement - Offer you our most

competitive cost - confirm the structure and mold order - Mould

deposit - Finish the sample and test - Sample delivery - Sample

confirm - Arrange the remainder mold cost - Place an order - Offer

related documents before shipment - Arrange the remainder cost -

DeliveryQuality Management Forman clearly understands

the quality importance for a company, therefore, every aspect from

product designing, production, to inspecting has been paid

attention to. We verify the material reliability in the designing

stage, then control every process will strictly comply with all

quality systems for best quality in production. Now, we can finish

dimension measuring, hardness testing, tensile strength testing,

coat thickness measuring, contact resistance testing, flame

retardant testing, and various environment testing in our

laboratory with many excellent brand instruments, like Keyence,

Nikon, Fischer, and so on.Custom sheet metal Process precision

copper terminal Stamping automotive spare partsCustom sheet metal

Process precision copper terminal Stamping automotive spare

partsCompany Profile Shenzhen Forman Precision

Industry Co., Ltd is a well-known new high-tech enterprise in

Shenzhen since 1999, we are mainly engaged in the development,

production, and marketing of OEM automotive components, Custom

Injection Plastic, and stamping metal parts, heat sinks, and

electronic connectors. Until the end of 2020, our total investment

capital is almost USD10 million, covering an area of up to 10

thousand square meters, and employ over 170 staff.

Forman has attained ISO9001, ISO14000, and IATF16949

certifications and achieved fully automatic production in precision

injection, insert molding, stamping, and assembly services from

2006. Our many facilities are introduced aboard such as the Sodick

slow-feeding NC wire-cut machine, Kyori and Yamada Punch, Fanuc

injection machines, and so on to offer high precision products and

high productivity. Meanwhile, we regard the high

technical capabilities then employ experienced technical and

management personnel for sophisticated technology and superior

quality. Besides, Forman has built up an independent testing

laboratory at home that can quickly finish the testing of

environmental, electric, mechanical, salt spray, and others.

Through the strong equipment base and experienced

technical support, Forman establishes a long-term cooperation

relationship with many world-famous companies and becomes their

Tier 1 supplier. Forman always insists on offering high-quality

automotive components, injection and stamping parts, and electronic

connectors, look forward to working together with you for mutual

development and benefits in the coming future.Cooperation

PartnerAwards&CertificationsCertifications & AwardsProduction

Area Forman has its mold-making, plastic injection,

metal stamping, and components assembly workshops. Here we can

design and make the tooling for auto-injection and progressive

stamping. Meanwhile, develop and produce custom plastic injection

parts, metal stamping parts, different auto components, and

connectors. And the machines in our assembly workshop were

designed and installed by our team, which can automatically finish

the assembly, inspection, and package for stable quality and high

productivity.Production Capacity Factory DisplayFAQFAQ:1:Q:

What kinds of metal material can you handle?A: Most of our products

are made of stainless steel, copper, SPCC, Aluminum alloy, and

carbon steel, we think most of the materials are available for us

and kindly forward your requirement and drawing for evaluation.2:

Q: How long can you offer us the sample?A: For the rapid sample

that it will only take 5~7

Related products about Good Tolerance Precise Stamping Electronic Spare Parts Metal Hardware

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup