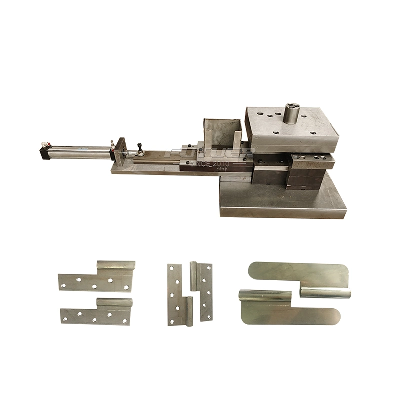

-- STAMPING MOULD --

-- PRODUCT SIZES --Detailed parameters

of the mould Mould Performance and Features1) Equipment: We

own Stamping machines, Hydraulic press machines, Auto-Turning

machines, CNC-Turning machines, Milling machines,Precision

wire cutting machines, more than 160 sets in total;2) Material:

iron, carbon steel, stainless steel, brass, copper, alloy steel,

aluminum, cold rolled steel with various plating;3) Surface

treatment: kinds of plating (Zinc, Nikel, Chrome, Tin, Ag);

Painting, Powder, Anodizing, E-coating, Silkscreen,

Heat treatment, Black oxid;4) Standard/ specification: OEM

service as per customers' requests, within-house tooling design &

fabricating;5) RoHS compliance for export;6) Quality assurance in

accordance with ISO9001:2008;7) Concurrent engineering capability

on product design;8) Just-in-time manufacturing capability to meet

customer's requirement;9) Tailor-made packaging method according to

customer's requirement. Brand NameOEMProduct NameMetal

Stamping Die/MouldTolerance±0.002mmMaterialSKD11, SKD 61, Cr12MOV,

D2, SKH-9, RM56, ASP23 etc.Design SoftwareAutoCAD, Solid works,

PRO/E, UGStandardISO9001Mould TypeCompound Stamping Die, Single

Stamping Die, Progressive die or according to Customer's

requirementsFirst Trial15-25 days after mold drawing confirmedMould

LifeDepends on customer's production capacityQuality confirmCan

send strip layout of die, testing video, inspection certificate and

sample of productPackagePE bags and carton for products, wooden

case for Die/mold, or as customer's requirements --

EQUIPMENT DETAILS --Detailed display of the

mould-- INSTALLATION COMMISSIONING

--Ships three or four times a week on average--

FUTUER TEAM --About Guangdong Futuer

Machinery Co., Ltd. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Punching Die Press Mould Progressive Stamping

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup