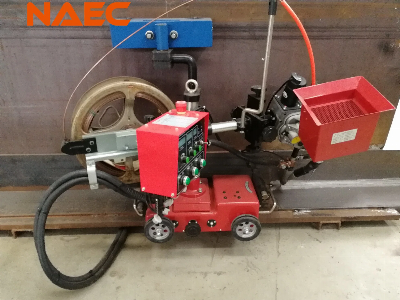

Automatic Butt/Corner Seam Welding Machine Features:1.

Applicable to inside and outside corner seam welding, suitable for

outside corner seam welding when the min. Distance from outer edge

of the bottom to the shell is 90mm2. Applicable to butt seam

welding of bottom plates3. With magnetic idler system4. Adopting

sub-arc welding technology5. Suitable for both Top-to-Bottom and

Bottom-to-Top Tank Construction Method6. More than 99% Qualified

first X-ray test.AUTO Automatic Butt/Corner Seam Welding Machine

can be applied to operate effective and efficient welding of

but-joint corner seam, lap-joint butt/corner seam, T type corner

seam and other different types. It mainly consists of four-wheel

drive welding trolley, welding controller, welding power source,

wire feeder, trolley travelling control system, welding flux

system, welding seam guiding mechanism, welding torch regulating

mechanism, cable and so on.When welding butt seam or lap-joint

seam, trolley travels on the rail for welding. When welding the

inside & outside corner seam and stiffener ring of vertical tank,

because of adopting special magnetic adsorption device, it can also

realize automatic welding without using rail. Automatic

Butt/Corner Seam Welding Machine has characteristics of advanced

structure, full functions, flexible control, easy operation, which

is a high efficient automatic welding equipment to improve welding

quality.Also, AUTO has specially designed Automatic Butt/Corner

Seam Welding Machine for LNG tanks, which can be used in double

shells for bottom plate seam welding. Tank Construction

Machines 1Girth Seam Welding Machine>Applicable to both

bottom-to-top and top-to-bottom tank erection>Adopting Sub Arc

Welding technology>Standard machine suitable for shell plate

width: 1.3M-2.8M>Max. Efficiency of AGW could be 30 times as

manual welding2Vertical Seam Welding Machine>Suitable for

tank plate wall thickness is from 10mm to 50mm>Motor frequency

inverter drive system>Weatherproof control box with digital

display for welding speed>Travel speed: 0~2200mm/min>Beveled

gear drive reducer, good locking ability in both

directions3Butt/Corner Seam Welding Machine>Applicable to

butt seam welding of bottom plates>With magnetic idler

system>More than 99% Qualified first X-ray test.>Suitable for

both Top-to-Bottom and Bottom-to-Top Tank Construction MethodFor

more information, pls contact us, thank you! /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Butt /Fillet Welding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup