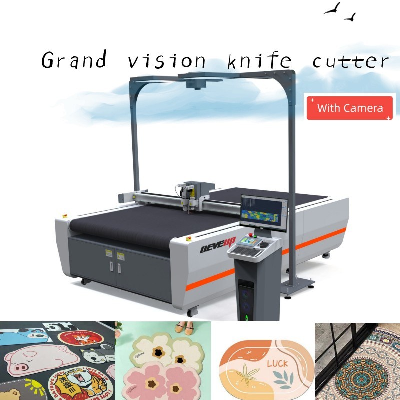

Automatic Printed Carpet CNC Knife Cutting Machine for car Mat

leather seat Upholstery Fiberglass Carbon Fabric Door Floor Blanket

Cushion Fur Curtain ClothIntroductions:It is equipped with

automatic feeding system, CCD camera image recognition system and

projection positioning system, which realizes automatic extraction

of image outline, automatic positioning and cutting, and solves the

difficult problem of printing fabric cutting and irregular material

cutting.Quickly cut a variety of printed fabrics, striped textiles,

and genuine leather with oscillating knives or drive-wheel knives.

Our digital oscillating knife cutting machine has a maximum cutting

speed of 7200mm/min, a maximum cutting thickness of 50mm, and a

repeatability of 0.02mm.Parameters:ModelDO1625FB/2030FB/1650FB

( Support customization )Working

area1600X2500mm/2000X3000mm/1600X5000mmMaximum cutting

speed1500mm/s(according to different cutting

materials)Precision±0.01mmCutting thickness50mm ( Support

customization )Material managementAutomatic feedingFixed material

methodVacuum + zone adsorptionVarious tool combinationsMilling

cutter+Pneumatic cutter+Marking penMilling cutter + round

cutter/oscillating cutter + indentation/bevellingRound

knife/oscillating knife + punching + markingOscillating Knife +

Round Knife + Chamfering/Creasing/Kissing/Drag KnifeCutting

materialsAll kinds of flexible materials,Sponge composite

leather,fabric,PVC,glass fiber,silicon,rubber,carbon

fiber,cardboard,KT board, PE,carpet,gasket,ABS and so

onTransmission systemDrive mode of Mitsubishi servo motor +

precision reducer; rack drive; Taiwan HIWIN guide

railVoltage220V/380V ±10%, 50Hz/60HzSupported file

formats PLT, DXF, DWG, AI, etc.Advantages:1. It can get

equipped with automatic feeding work platform and super discharge

system, which saves time for manual typesetting, improves work

efficiency, and saves 10% of materials;2. The traditional manual

cutting efficiency and precision can no longer meet the needs of

the market. The cutting accuracy and efficiency of the carbon fiber

cloth automatic cutting machine can meet the needs of different

industries;3.It adopts the advanced vibration knife cutting machine

technology, the edge of the cut will not appear yellow and

scorched, there is no odor at the processing site, and the cutting

edge is smooth;4. High degree of intelligence, combining automatic

feeding, automatic nesting and automatic cutting system, which

reduces production costs and improves production efficiency.Various

cutter heads can meet different material cutting requirements:Our

cnc digital knife cutting machines are mainly for

cutting various flexible materials such as carbon fiber,

fiberglass, carbon fiber, leather, cloth, EVA foam, soft glass,

prepreg, carbon felt, rubber, graphite sheet, silica gel, sound

insulation, carton box, paper, honeycomb profiles, etc. With a

variety of tools and pens to meet the cutting needs of different

materials, and provide a variety of personalized cutting

services.Machine Details: Colorful & touch control operation

panel, with more intuitive operation interface, which can directly

input processing data, set processing speed and knife depth,

support screen automatic protection, and protect processing

data,feature-rich and user-friendly operation A variety

of tool combinations, equipped with intelligent prop interchange

system, can cut different materials to achieve different tasks, and

multiple tool heads can work individually or in concert. Powerful

function, fast running speed, high processing accuracy, truly

multi-purpose machine. We insist on using 6mm thick, 60mm

diameter steel pipes, and adding load-bearing brackets in the X and

Y axis directions every 80-100mm span. We use 60mm thick cast iron

in the frame and guide rail mounting position and use CNC gantry

machining center for planing and milling. Our bed has the

characteristics of heavy weight, good load-bearing capacity and

high hardness, which ensures the accuracy and stability of the

oscillating knife cutting machine at high speed. We guarantee

that the machine will not be deformed in 10 years. The beam

adopts the extrusion process of aviation aluminum alloy die,

which ensures the stability and high precision of machine

operation at high speed, especially suitable for some industries

that require high precision, such as sealing gasketsImported famous

brand helical gear rack, quenching and hardening treatment. High

precision, strong load-bearing capacity, smooth running at high

speed and less noise.Taiwan PMI 20mm high precision linear guide,

high positioning accuracy, high repeatability. Low friction

resistance, high rigidity four-way load design, high speed and long

time operation to maintain high precisionSafety protection device.

Highly sensitive collision avoidance system and red light brake

system. When the machine is cutting at high speed, it can

effectively protect safety of the operator. The worktable is

a high precision and strength aluminum h

Related products about Automatic Printed Carpet CNC Knife Cutting Machine for Car Mat Leather Seat Upholstery Fiberglass Carbon Fabric Door Floor Blanket Cushion Fur Curtain Cloth

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup