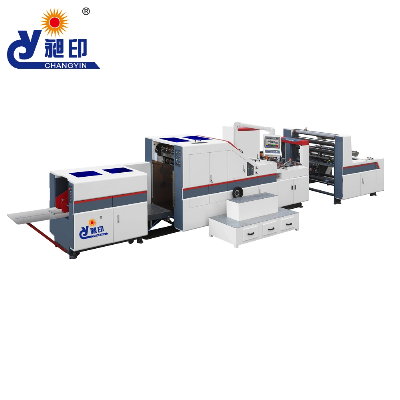

IntroductionAdjustable roll-to-square bottom paper bag making

machine has the advantages of high speed, high production

efficiency, and wide adjustment range. It is designed to

manufacture square bottom paper bags from paper rolls in blank or

printed and can complete side gluing, tube forming, cutting, bottom

impressing, bottom gluing, bottom forming, and final product output

within one time. Controlled by a PLC system, equipped with a touch

screen and servo motor for bag length control, this machine can

produce a variety of specifications paper bags. It is a piece of

ideal equipment for making paper bags for foodstuff or shopping

bags.Characteristic1. Use hydraulic lifting for material handling

and an automatic tension control system for unwinding.2. Side

gluing uses Italy ZATOR.3. Automatic error correction uses Italy

SELECTRA.4. Paper tube forming device with thumb-cut function.5.

Automatic stop for having no material.6. Center clip, drum wheel

clamp, and drum wheel mechanical finger all use spider synchronous

adjustment mechanical design, which can significantly reduce the

adjustment time for replacing size.7. Use a German KEB servo with a

SICK photoelectric eye, which can accurately track the printed

material.8. Equipped with automatic lubrication supply system and

jams alarm system.ModelCYFD-460Bag Length260-533mmBag

Width220-460mmBag Bottom Size80-200mmPaper Bag Speed200pcs/minPaper

Thickness60-150gsmPaper Roll Width600-1300mmPaper Roll

Diameter1300mmInner Diameter of Paper76mmTotal Power15kwMachine

Weight10000kgMachine Size (L×W×H)9200×3000×1800mm/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about CYFD-460 Full Automatic Square Bottom Food Bakery Window Paper Bag Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup