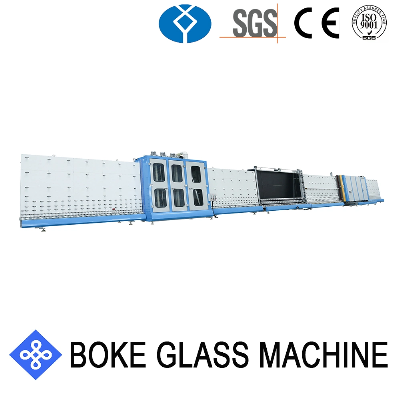

1.1. Brief introduction of insulating glass production line

LBP2000Q with gas filling on line(for max. glass size:

2000*3000mm) This Vertical Insulating glass machine is

composed of 1) loading section, 2) washing and drying section, 3)

transmission and storage section, 4) light inspection and spacer

bar attaching section, 5) transmission section,

6) inside assembly and inert gas filling

section, 7)storage and unloading section. With special design,

it can wash Low-E glass effectively with high speed. This line is

controlled by PLC and realizes the automatic control and frequency

control of the motor speed of the whole line. It adopts advanced

assembly technique and solves the problems of uneven press and

misplacement of the glass. The assembly section adopts limit switch

and cylinder tank whose travel distance can be adjusted, making the

operation easy and the location precise and the movement

reliable.There are two operation methods in the control panel

'automatic' and 'manual'. If the separate operation of each

section or maintenance is needed, the 'manual' operation method is

needed.Three pair of brushes import from USA, DuPont brand. Which

is well known for its fine quality and durable in use. They can

wash Low-E glass. Automatically distinguish the coating side

of coated glass and Low-E glass.Adopt waterproof bearing without

oil lubricant, SKF brand import from Sweden. The washing body

adopt stainless steel and anti-rusting materials.The PLC and other

electric elements adopt Schneider brand, import from France.With

automatic inert gas filling function in the press section. The

inert gas filling efficiency is more than 95%1.2 Performance

characteristic for Insulating Glass Production Line:1)

Automatically distinguish the coating side of coated glass and

Low-E glass, indicated by alarm.2) Static state put glass when add

glass material, ensure safety in production.3) The washing machine

adopts stainless steel and other corrosion resistant material,

good waterproof, security, clean, and long service life. Equipped

with sponge roller, which makes the washing and drying more

efficiency.4) Three pair of brushes, one pair with hard brushes

which can keep away from the glass when wash Low-glass; while the

other two pair is soft brushes, which can wash Low-E glass and

won't break the coating.5) Can process 3~18mm thickness glass, with

wide using range.6) It can process same edge double layers and

triple layers insulating glass with high efficiency.7) The bearing

take famous brand SKF, which smooth with oil-less powder. In this

case it will keep water free from oil and keep water clean.8) Adopt

low-voltage electric apparatus component, the sensor, PLC, whole

process automatically control machinery.9) Treat the surface of

plate guard through baking, powder coated. Appearance is beautiful

and wears well.10) The dry part use circulation hot wind that

ensure the dry effect for glass and reduce the noise.11) The press

section can be opened in large journey to maximum 500mm, easy to

maintenance.12) In the press section, there is inert gas filling

function. The inert gas filling efficiency is more than 95%.13) PLC

control system with touch screen interface. Easy to operate and

automatically self-diagnosis the fault of the production line.14)

Glass position memory function, can easily and quickly deal with

the inconvenience caused by errors, improve the production

efficiency.1.3 Insualting Glass Production Line with Argon Gas

Filling on line Technical Data and Specification

Model LBP2000Q Max processing glass size 3000*2000mm

Min processing glass size 450*200mm Single glass

thickness 3-15mm Cleanout speed 3-10m/min Work

speed 15-45m/min Power supply 3P.

380V/50Hz Total power 41.35Kw (include heater

10Kw) Inert gas type Argon, Nitrogen, etc. Inert gas

efficiency More than 95% Total

weight 8500Kg Outline

Dimension 22800*2500*3180mm 1.4 Insulating Glass

Production Machine Function and features

Insulating Glass Production Line Section 1

Loading SectionLow-E glass automatic diagnosis system. The back

board is high quality Aosong board through the NC machining and

wheel combination, makes it beautiful and durable. It is the first

section of the line and its main function is to transmit the glass

to the washing and drying section. The transmission is carried out

by chains driven by the motor and the transmission speed is stable.

It runs at the same speed of the washing and drying section and the

speed can be changed by the inverter. It can avoid the back board

bending and deformation, waterproof and anti-acid.

Insualting Glass

Production Line Section 2 Washing and Drying SectionStrong pointsa.

The water in the washing tank, you'd better use the purified

water.b. Mechanical adjustment wind of knife, without any manual

operation. According to the thickness of the glass, mechanical

detection and adjustment of the wind knife.c. 15kw fan, two pairs

of

Related products about Automatic Large Size Double Glazed Aluminum Window and Door Gas Filling Vertical Washer Dgu Ig Unit Panel Press Insulated Production Insulating Glass Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup