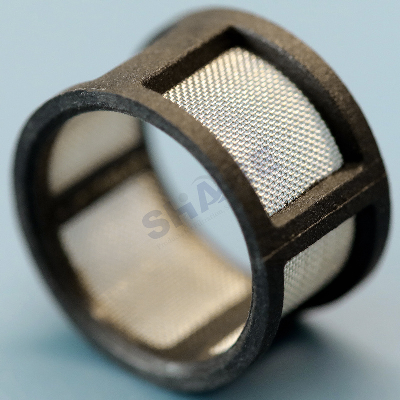

A screen filter is a type of water purification

using a rigid or flexible screen to separate sand

and other fine particles out of water for irrigation

or industrial applications.SHARE'S reusable plastic screen

pre-filter are commonly used in residential and commercial

installations to protect a water purifier system from debris that

might enter the line and cause blockage of the emitters. The low

maintenance, inexpensive screen filters provide reliable and

trouble-free operation by removing fine sand and other particles

that could otherwise block the small water passages of the drip and

micro sprinklers.Product Parameters Item NameReusable

pre-Filter for Whole House, Tap Water Filter, Stainless Steel Mesh

pre-Filter for pre-Filtration City/Well

WaterSizeCustomColorBlack+Red+Blue+Green+BrownFit for Whole

house, solar power, water heater, water purifier, pure water

machine, water dispenser etcQuality Warranty3 YearsBody

MaterialsPlastic and stainless steel meshApplicationWater Purifier

SystemProperties1. A front water purifier is installed to extend

the life of the wading device, and after filtering impurities,

water flows to other wading devices, effectively extending the

design life of water in the entire house and reducing maintenance

costs. And ensure the safety of water.2. Our filter element can

change the water quality problem so that you can improve the

drinking environment according to your taste. Made of stainless

steel metal, it has a long service life, high durability, a large

amount of water, and excellent filtration effect.3. Easy to clean

and easy to install4. Filtration accuracy is as high as 10 to 2000

microns, harmful substances can be effectively removed, and toxic

substances such as lead do not precipitate. ApplicationsHome

appliance, automotive, irrigation, hydraulic, medical and health,

food and beverage, electronics and aerospace. Plastic

material selectionPlastic molded filters are highly customizable

filters that can be manufactured into countless shapes and sizes.

These filters can be used in high temperature environments.One of

our core competencies is the production of plastic screens and

filter elements. The application and the requirements for the

plastic part are decisive before injection molding. The plastic we

select are icluding PE, PP, ABS, PC, POM, PBT, PA, PPA to

PEEK.Material property is an important know-how to injection

molding. It is highly related with molding quality, finish and

cost. Our team devote this knowledge and experience to the

molding products of our customers. From various thermoplastic (PA,

PP, PC, POM, PET, ABS and Peek) to thermosetting (PE, Epoxy and

Silicon) even combined plastic materials (such as glass fiber), we

put material property as a must-evaluation when design tooling, so

we would also help to suggest equivalent materials for quality

improvement or cost reduction. Mesh SelectionThe selection of

filter mesh material has a crucial impact on the final plastic

injection parts. SHARE FILTERS micro rated precision filter

fabrics perfectly meets our customer's filtration

requirements. Nylon from 10 to 2000

micronPolyester from 10 to 2000 micronPolypropylene from 75 to 2000

micronStainless steel: most alloys, 10 to 2000 micronOther metals:

most alloys including epoxy and coatedDetailed PhotosFor more

information or photos, please feel free to contact SHARE and we are

always here for you. FAQ1. How long does a quotation take?In

most cases, SHARE will respond within two days. If something

in RFQ need be confirmed, we will notify you soon.2. How quickly

can I get my order finished?Production lead time is based on the

quantity. Usually, it takes 5 to 15 working days for us

to complete for mass production once you pay the order.3. What

about your quality control?Self-inspection in every process by the

production operator. Spot inspection and final inspection executed

by QC.4. What kind of payment terms do you accept?T/T and LC and

more.5. What's your largest advantage?SHARE specialize in high

precision mold and filters with professional technical team

and quality guarantee and management for more than 30 years.6. Can

plastic molded filter specifications be customized?Yes, the

filter's materials, dimensions, shape, construction method, mesh

size, and applications are all fully customizable by SHARE.7. Do

you need drawings for production?If you have drawing (2D, 3D both

available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT,

PRT, IPT etc.) it'll be better for us to proceed.If you don't have

drawing, it doesn't matter. SHARE can consult with you to

make a drawing based off a description or image of the filter you

may have. No drawing is necessary to get started.8. How do I know

my design will be kept confidential?We sign and adhere to any

non-disclosure or confidentiality agreement with our customers. We

also have a strict confidential policy within our factory and never

allow any proprietary information to be disclosed to a third

party.9. W

Related products about Water Purifier, Water Filter System, Reusable Pre-Filter for Whole House, Tap Water Filter, Stainless Steel Mesh Pre-Filter for Pre-Filtration City/Well Water

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup