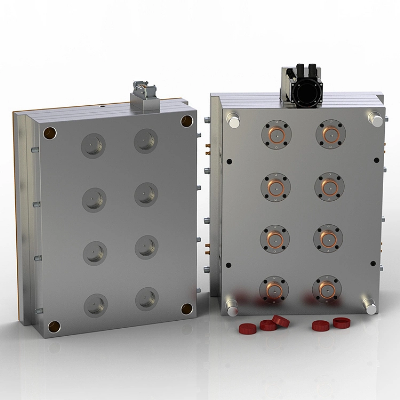

Product Description Plastic injection

molds and mould manufacturer1-Start from part design analysis2-Mold

design drawing and DFM report available so you can see how is the

mold going to be before mold making3-If product is complex,moldflow

report will be present as well4-In house mold making shop ensure

you mold quality under well control.5-Normally it takes 15-25

working days to make mold,precise time depends on part

design Product DescriptionODM plastic injection moldingPlastic

Materials:PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF,

PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.Standard:ISO9001:2008Other

materials:Rubber, Slilconce rubber, LSR,Aluminum,

Zinc,Copper...Metal...etc.Quality:RoSH and SGS standardFeature:Non

marking and Non flashSize:According to your 2D, 3D

DrawingColor,Quantity,Unit price,Tooling cost,Tooling size:To be

discussedPackage:Standard exported Wooden box packed, Fumigation

process(upon required)Mold Building Lead Time:T1, 15-25 Working

days, Part measurement report (upon required).Export

Country:Europe, Japan, America, Australian, UK, Canada, France,

Germany, Italy...etc.:Experience:13 years experience in plastic

injection mold making and plastic prouducts produce.To be

discussedIn-Mold Decoration, Injection Mould, Plastic Mold,

Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold,

Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression

Mold, Cold Runner System LSR Mold,...etc.Mould Base:Hasco Standard,

European Standard, World StandardMould Base Material:LKM, FUTA,

HASCO, DME,...etc. Or as per Customer's Requirment.Surface

Finish:Texture(MT standard), High gloss polishingCavity/Core

Steel:P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312,

2379, 2316, 2083, Nak80, 2767 ...etc.Hot/ Cold RunnerHUSKY, INCOE,

YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made

brand...etc.Mould Life:5,000 to 1,000,000 Shots. (According to your

working environment.)Design & Program Softwares:CAD, CAM, CAE,

Pro-E, UG, Soild works, Moldflow, CATIA....etc.Equipments:High

speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic

Injection Molding Machine for trial out mold from 50-3000T

available.How to order Company ProfileCEMAL Enginnering

, professional plastic mold manufacturer in China, we focus on

design and manufacturing plastic molds forthe Automotive, Home

Appliances and other sectors.Excited and ready to help support your

project from the early stages of part development and tool design

to fabrication and parts production via professional engineering,

manufacturing, and project management, we are confident that our

service level is second to none.When you choose CEMAL- whether it's

for a single part, a small run or a multi-year contract - you'll

get the same attention to detail, the same problem-solving

approach, the same quality solution. That's the CEMAL

promise.Making our customers satisfying, Keeping our customer

successful is the goal of CEMAL.Why Choose CEMALAre you planning to

get a supply of custom injection molds and probably do not have an

idea of which Company is likely to offer effective products? If

yes, then this article will be a perfect guide for you as it tries

to highlight various reasons as to why you should choose Loxin mold

as your supplier in injection molds. There are thousands of

injection mold manufactures in China and therefore, determining the

ideal company to partner with can quite be difficult. Not all

factories offer genuine products or even provide the various

services at affordable prices and there is thus the need to be

careful on the company that you settle for. CEMAL mold has been in

existence for more than 10 years now and has proved to be the

leading producer of the custom injection mold through the exemplary

services to the various customers. It would thus be a wise choice

to consider us as your partner in supply of mold related products.

Below are some of the reasons as to why you should consider our

companyAll products are availed at affordable pricesAt CEMAL mold,

all manufacturing process is done within the company and nothing is

ordered from other companies and hence ensuring that all products

are traded at the factory price to the various customers. We do not

supply our products through any middle persons but rather directly

to our clients. Brokers usually charge higher prices on the

products in order to get their profits and therefore that is why we

avail all products directly to the users to avoid such costs and

hence avail the products at affordable prices to our clients.Highly

experienced in production of mold As mentioned earlier on, CEMAL

mold has been in operation for more than 10 years and therefore has

efficient knowledge in production of molds and the related services

to out esteemed customers. We have transacted with various

customers even in the European countries and have always given a

positive feedback on our services. If you still don't believe in us

then you can refer from yo

Related products about China Manufacture Plastic Parts Injection Mould for Mobile Phone

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup