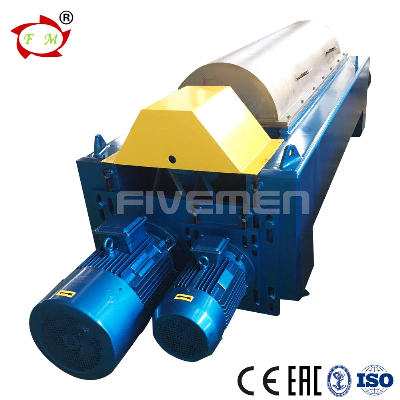

In the field of environmental protection, we use the automatic control system that boasts high length-diameter ratio, high speed, small differential speed. High length

diameter ratio increases the material clarification and dewatering time inside the machine; high speed generates great centrifugal force, leading to thorough dehydration of material; small differential speed reduces spiral stirring the materials, increases the dewatering time, therefore improves the separation in sludge thickening, dewatering and clarification, which can obtain drier solid residue and clearer clarification liquid compared to other decanter centrifuges; in order to maintain the best dewatering effect, the operation parameters are subject to automatical regulation with the amount and quality of sludge entering into the centrifuge, which ensures normal operation of the machine and stable water content in the discharged sludge. If the condition of sludge entering the machine changes greatly, beyond the regulation capacity of the machine or the machine itself fails, the machine will shut down automatically and alarm.Our centrifugal sludge dewatering machines can achieve sludge thickening, sludge dewatering as well as thickening and dewatering integration. The decanter centrifuge can be adjusted to suit individual requirements by varying: 1. Bowl speed to ensure the exact relative centrifugal force required for optimized separation. 2. Differential speed, for optimized balance between liquid clarity and solids discharge capacity. 3. Pond depth in the bowl for optimized balance between liquid clarity and solid dryness. Application: The machine is

widely used in the production of chemical , printing, metallurgical

coal mine, oil production, metallurgy ,iron and steel, fabric

,food, drink, pharmacy starch, dyes and so on, and it can also

solve industrial and municipal wastewater. By use it, solid can be

dehydrated, liquid can be

clarified, etc. 1. Solid phase dehydration: dehydration effect for processing materials of solid particles. 2. Particle size classification: used in the removal of material of large diameter solid particles. 3. Liquid clarification: used for removing solid particles in the suspension liquid are clarified. Working

Principle The sludge dewatering system consists of five

parts: (1) Sludge feeding system, (2) Flocculant

dosing system, 3) Thickening and dewatering system, (4)

Mud cake delivery system, (5) Electronic control device of sets of

system; Thickening and dewatering of sludge arising from

urban life, power plant, petrochemical refinery, coking as well as

from industries.Technical parametersTypeBowl diameter(mm)Bowl

length/ Bowl diameterBowl speed(r/min)Main

Power(Kw)LW1801802.5-72060003-5.5LW2602603.0-450007.5-11LW3553552-4.5400011-30LW4204203-4.1360018.5-37LW4504502-4.4360018.5-37LW4804802-4.2320018.5-45LW5005002-4.2320018.5-55LW5305302-4320022-55LW5805802-4280030-55LW6206202-4280037-110LW7607602-3.5250055-132Note: In case of differences between the table and the user manual, the latter shall prevail.Model: LW450X1720Drum diameter: 450mmDrum length: 1720mmDrum speed: 0-3300r/min(adjustable)Speed Difference: 0-30r/min(adjustable)Length Diameter Ratio: 4.2Motor Power: 22KWAuxiliary power 7.5KW(In power generation state)Weight: 3600kgCapacity: ≥7.5T/hApplication area: animal

oil,sludge dewatering chemical and waste oil so

onWater content after separation: ≤10%Oil content after separation: ≤0.2%TypeBowl

diameter(mm)Bowl length/ Bowl diameterBowl speed (r/min)Main

Power(Kw)LWS3553553.3-4.5400015-18.5LWS4204204.1360022LWS5005004.2300030LWS5305004.2300030LWS5805804.1280045LWS6206204280045Note:

In case of differences between the table and the user manual, the

latter shall prevail.Main partsPackaging &ShippingRelated

product &Certificate

If you want to get more information,pls

contact usPre-Service 1. 24 hours onlinne consult

and service2. Introduce the details of products to the customers,

answer the question raised by customer at firstly;3. Providing the

operation , installation and working video for customers.4.

Providing the different solutions for choice according to the needs

and requirements of customers; Sale Service1. Ensure new

product with high quality before delivery;2. Packing according

to the export requirements and shiping carefully;3. Provide

full set of documents as customer's requirements.4. Providing one

year sparing parts for you for free.5. Delivery on timeAfter-sale

Service1. Help to install and debug the equipment, Our technicians

could be dispatched foroverseas service.2. Provide 24 hours

techincal support by e-mail or phone;3. Abundant spare parts in

stock are available to provide.4. Help customers slove any other

questions about products or other aspect;5. Your workers could

get trained both in our factory and yours. Service

Commitment1. We will provide one-year warrantee to make sure your

machine

Related products about Oil and Water Separator Sludge Dewatering Manufacturer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup