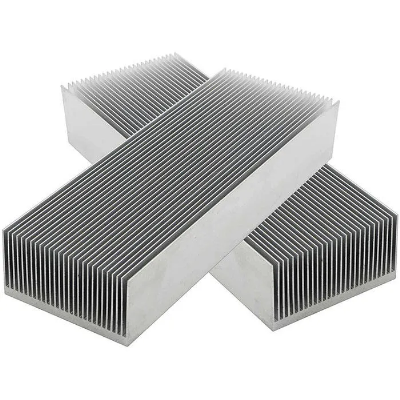

China Industry Extrusion Aluminum Extrusion Profile Factory LED

light Aluminum Profile Product Description Product Name Aluminum

heat sink disipador 110(W)*40(H)*165 (L)mm with black anodized

surface Material AL 6063 T5 Detailed Size As the below

drawing,or as per custom design Max Aspect

Ratio( Fin Height / Fin Gap) More than 20 times aspect ratio

heatsink can be extruded by 800 Tons--6000 Tons extruding machine

by most advanced technology Max Width Ultra wide extruded heatsink

can be made by our unique friction welding technology Standard Mold

Qty 30,000+ sets standard molds in stock for your option,saving

your R&D cost Sample Service Samples with differernt sizes are

availabe for prototypes test within 1 week Production Process

Profiles Extruding---Cutting---CNC Machining(Milling,

Drilling,Tapping)---Deburring--- Cleaning--- Inspecting--Packing

Surface Treatment Degreasing,(Black) Anodizing,Sand

Blasting,Painting,Chromating and Laser marking Reference Standard

GB/T 3190-2008,GB/T 14846-2008,ISO 2768 Experience More than 20

years professional manufacturing experience Application LED

Lighting,Inverter,Welding Machine,Communication Device,Power Supply

Equipment,Electronic Industry,Thermoelectric

Coolers/Generator,IGBT/UPS Cooling Systems,etc. Products ShowMore

than 4000 sets of existing aluminum heatsink moldsgiving you more

choices, saving you mold costsSupport small batch production,

welcome to consult customer service!Main Categories Extruded heat

sinks use an extrusion manufacturing process where material is

pushed through a die of the desired cross-section. Extruded heat

sinks can have very complex cross-sections and use brittle

materials. Extruded parts have an excellent surface finish and are

ideal for additional finishes such as anodizing or electroplating.

FM uses high thermal conductivity aluminum alloy A6063 200 W/(m-K),

which is not used by most heatsink manufacturers because it is

"sticky" and difficult to work without a good process recipe.

Extruded heat sinks are suitable for high volume production because

of their relatively low NRE. Molds are usually made using wire EDM

and mold lead time is usually 4-6 weeks. Most cost-effective when

post-machining is not required, as additional CNC machining may

relieve stress that can lead to distortion. This can be minimized

with special heat treatments to limit failures due to stress.

Extruded heatsinks offer thin fins and an approximately 8:1 aspect

ratio for optimal heatsink performance.One of the most common

extruded heat sinks is the Platefin extruded heat sink, which

extracts heat by natural convection. Extruded plate fin heat sinks

use straight fins running the entire length to maximize the surface

area of the heat sink. Heatsinks can be additionally machined to

form crosscuts with similar effects to elliptical fin

heatsink Our company was established in 2011 in

Dongguan City, Guangdong Province, with total plant area of over

40,000 square meters and a workforce of over 500 personnel.At the

same year, we set up our company, we only processed die-cast parts.

Three years later, our business was enlarged from metal product

design, tooling design and production, aluminum and zinc die

casting, aluminum extrusion and deep processing, CNC machining,

laser cutting, stamping, copper pipe forming, surface treatment to

parts assembly.Our products are widely used in lighting industry,

construction, electronic products, electronic home appliances,

telecommunications, medical devices and equipment, machinery

accessories, furniture, automobiles and tools, transportation, and

aviation.Backed by Experienced and Aggressive TeamWe have an

experienced, dedicated, innovative and responsible engineering

management team and well trained and skilled workers. Our joint

efforts can always guarantee our customers' projects be quickly and

correctly handled. This is the key point why we have stay in this

field and won high sales.Competitive Products & ProcessingOur

target customer is the ones only buy the parts and do the assembly

by themselves, it will greatly increase customers' marketing

competitive power and their margin room. The cost will be only

40%-50% compares they buy the finished lights from the light

factory directly.1.How can I get the price? "-We usually quote

within 24-48 hours after we get your inquiry(Except weekend and

holidays). -If you are very urgent to get the price, please email

us or contact us in other ways so that we can offer you a

quote." 2. Can I buy samples placing orders? -Yes.Please feel

free to contact us.3.What is your lead time? -It depends on the

order quantity and the season you place the order.4.What is your

payment term? T/T,Letter of Credit or Paypal.This is

negotiable.5.What is the shipping method? "-It could be shipped by

sea,by sea or by express(EMS,UPS,DHL,TNT,FEDEX and ect). Please

confirm with us before placing orders."6.How do you make our

business long-term and good relationship? "-1. We keep good quality

and competitiv

Related products about Large Square Big Power Anodizing Aluminum Profiles Extrusion Amplifier LED Heat Sinks Radiators

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup