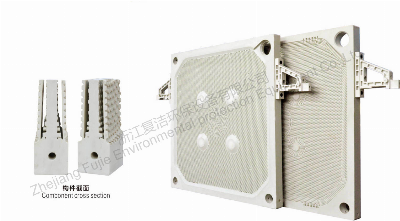

Product descriptionThe diaphragm filter plate is composed of two

diaphragms and a core plate. External media (such as water or

compressed air) is introduced into the chamber between the core

plate and the membrane, causing the membrane to bulge and

compressing the filter chamber composed of the diaphragm filter

plate and the box filter plate, thereby better separating and

improving the solid content. Polypropylene filter plate diaphragms

are generally welded as a whole, and the welded diaphragms cannot

be replaced. Due to the integrated structure, there are no

unnecessary gaps, seals, special material fixtures, etc. required

for the split type, which means there are no unsanitary dead

corners, sterilization is more thorough, and the application range

of filtering materials is wider. Polypropylene, as a thermoplastic

material, has recyclability and is more convenient and economical

than rubber in manufacturing membranes. It can significantly

improve the solid content and sealing performance of the filter

cake, shorten the filtration time, and significantly improve

production efficiency.The company provides all series from

800mmX800mm to 2000mmX2000mm Product

display Filter cloth workshopOur Advantages1. Good

chemical resistance, wide temperature range (-10~90 ºC), excellent

fatigue life, and high-temperature steam sterilization resistance2.

Excellent chemical stability, with filter materials containing

certain acidity, alkalinity, and temperature, the service life can

be increased by at least 50%3. The hydrophobicity of the

polypropylene filter plate material ensures a 45% increase in

drainage efficiency during the filtration process4. Our

polypropylene diaphragm filter plate can achieve a pressing

pressure of 1.6MPa, which is far superior to rubber filter plates

and also better than peers5. Low pressure filtration, medium and

low pressure washing, and high pressure pressing. Greatly reduce

washing water and improve the washing effect. Shorten the entire

filtration cycle and increase the solid content of the filter cake

to over%.6. The pressing medium can be fluid media such as air,

inert gas, water, oil, etc., which can meet the needs of different

industries.7. The pressing pressure can reach up to MPA, and it is

equipped with a pressing safety protection system to avoid damage

to the diaphragm caused by misoperation.8. The lighter weight of

the filter plate makes the handling of the filter components

easier SpecificationsFeedingModelPlateThickness(mm)board

thick(mm)Inlet diameter (mm)Inlet thickness(mm)Washing

holesize(mm) Maximum feed pressure MPaStandard drivepipeOpen

flow PP Water faucetLiner intake connector

clipSeptummembraneClipmaterialqualityPressing methodFeed pressure

MPaPressing pressure MPa≤50ºC≤90ºC≤50ºC≤90ºCSG polypropylene

diaphragm filter plate - split type (double sided flat

type)CenterSG1000 diaphragm

plate307010068500.60.410.6PP1/23/4PPPneumatic

press (62) 304SG1000

diaphragm plate3070100625010.61.613041/23/4304Hydraulic

pressXII1000 filter

plate30651003550 1/2 CenterSG1250307012566650.60.410.6PP1/23/4PPPneumatic

press (60) 304X1250

filter

plate30601253065 1/2 SG1250

diaphragm plate3070125606510.61.613041/23/4304Hydraulic

pressXII1250 filter

plate30651253565 1/2 CenterSG1500

diaphragm plate408015078800.60.410.6PP1/23/4PPPneumatic

press (66) 304X1500

filter

plate40801504080 1/2 SG1500

diaphragm plate4085150718010.61.613041/23/4304Hydraulic

press16X1500 filter

plate40851504580 1/2 SG

polypropylene diaphragm filter plate - integral typeCenterSG8000

diaphragm plate3065100 500.60.410.6PP1/23/4 Pneumatic

pressX800 filter

plate3060100 50 1/2 SG8000

diaphragm plate3065100 5010.61.613041/23/4 Hydraulic

pressXII800 filter

plate3065100 50 1/2 CenterSG1000

diaphragm plate3070100 500.60.410.6PP1/23/4 Pneumatic

pressX1000 filter

plate30601003050 1/2 SG1000

diaphragm plate3070100 5010.61.613041/23/4 Hydraulic

pressXII1000 filter

plate30651003550 1/2 CenterSG1500

diaphragm plate408015067800.60.410.6PP3/43/4 Pneumatic

pressX1500 filter

plate40801504080 3/4 SG1500

diaphragm plate4080150678010.61.613043/43/4 Hydraulic

press16X1500 filter

plate40851504580 3/4 Product

catalog About usZhejiang Fujie Environmental

Protection Equipment Co., Ltd. was established in June 2016 and is

a wholly-owned subsidiary of Shanghai FujieThe company has 60000KN,

80000KN, and 120000KN ultra large injection and pressure equipment,

with the largest tonnage of oil pressure machines in the industry

and multiple three axis machining centers and several five axis

machining centers, making it the first enterprise in the industry

to use five axis machining.The unique raw materials and formulas

for filter plate manufacturing ensure various performance

indicators and mechanical strength, and the material is uniform and

dense. The company has passed three major management system

certifications: ISO9001, ISO14000, and OHSA45001.

Largest tonnage

Related products about Leading Supplier 800-2000 Series High Pressure PP Membrane Plate for Sewage Treatment and Sludge Dewatering

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup