Company ProfileSTMPB INDUSTRY was established in 2021; We have

two bearing brand which STMPB INDUSTRY and YUPO were founded in

2021.STMPB INDUSTRY is our international brand which mainly faces

overseas market.YUPO is the domestic brand which manily faces China

market.STMPB INDUSTRY bearing headquarters is mainly located

in Zhengzhou, Henan Province, and the main production base is

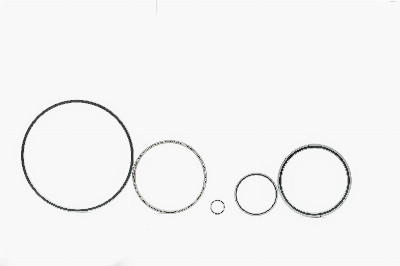

located in Luoyang, Henan Province. The main products of STMPB

INDUSTRY bearings are high precision bearings and customized

bearings. The main products of STMPB INDUSTRY are precision angular

contact ball bearings, ball screw bearings and bearing units,

thin-wall equal-section bearings, precision cylindrical roller

bearings, YRT bearings, precision cross roller bearings, precision

slewing bearings and non-standard customized products.STMPB

INDUSTRY bearing R & D team mainly composed of professors and

doctors, the R & D strength is very strong, to provide customers

with the best quality production solutions and solutions. STMPB

INDUSTRY bearing with precision production equipment, can provide

customers with stable P4,P3,P2 grade products.STMPB

INDUSTRY bearings are mainly applied in CNC machine tools,

robots, medical machinery, precision instruments, petrochemical and

other fields. So far, STMPB INDUSTRY bearings customers throughout

South America, Southeast Asia, the Middle East, Europe and other

regions, by the world's customers consistently high

praise. Product Parameters Bearing

designationsBoundary dimensionsLoad

ratingWeightdDd2D2CrCorin.mmin.mmin.mmin.mmKNkgCSI040374101.64.75120.654.277108.644.473113.6110.39.30.20CSI042374.25107.9551274.527114.994.723119.9610.59.90.21CSI045374.5114.35.25133.354.777121.344.973126.3110.710.40.22CSI047374.75120.655.5139.75.027127.695.223132.6611.010.90.23CSI0503751275.75146.055.277134.045.473139.0111.211.50.26CSI055375.5139.76.25158.755.777146.745.973151.7111.512.60.27CSI060376152.46.75171.456.277159.446.473164.4111.913.60.29CSI065376.5165.17.25184.156.777172.146.973177.1112.214.70.31CSI070377177.87.75196.857.277184.847.473189.8112.515.80.33CSI075377.5190.58.25209.557.777197.547.973202.5112.916.80.35CSI080378203.28.75222.258.277210.248.473215.2113.217.90.38CSI090379228.69.75247.659.277235.649.473240.6113.720.00.43CSI100371025410.75273.0510.277261.0410.473266.0114.222.20.48CSI1103711279.411.75298.4511.277286.4411.473291.4114.724.30.53CSI1203712304.812.75323.8512.277311.8412.473316.8115.226.40.57CSI1403714355.614.75374.6514.277362.6414.473367.6116.030.70.69CSI1603716406.416.75425.4516.277413.4416.473418.4116.835.00.78CSI1803718457.218.75476.2518.277464.2418.473469.2117.639.30.88CSI200372050820.75527.0520.277515.0420.473520.0118.243.60.98CSI250372563525.75654.0525.277642.0425.473647.0119.854.21.22CSI300373076230.75781.0530.277769.0430.473774.0121.164.91.46Detailed

Photos Installation Instructions(1)Inspection of components

before installation Clean the bearing housing or other mounting

parts, remove the dirt, and confirm whether the burrs of each part

have been removed. (2) Install it on the bearing seat or

shaft Because it is a thin-walled bearing, it is easy to tilt

during installation. Please use a plastic hammer to find the level

and tap it evenly in the circumferential direction, and install it

little by little. Until you can confirm the contact surface is

fully seated by sound. (3) Installation method of side

compression flange 1. After placing the side

compression flange in position, place it in the circumferential

direction. Shake back a few times to adjust the position of the

mounting bolts. 2. Install the compression bolt, and

make sure that there is no deviation due to the bolt hole when

tightening the bolt by hand. The distance causes the bolts to be

difficult to screw in. 3. The tightening of the compression

bolt can be divided into 3-4 parts from temporary tightening to

final tightening stage, repeat the tightening in the order on

the diagonal. When tightening is divided into two parts When

tightening the inner or outer ring press bolts, the integral outer

ring is often tightened during the tightening process. Or the inner

ring can be adjusted and rotated a little to make the outer ring

divided into two parts or the deviation of the inner ring is

corrected. Special design: If you need special structure

(such as outer ring with mounting holes, inner ring without holes,

etc.), non-standard size, special materials or high precision

requirements, etc., please contact.

Certifications Technological Support28 professional mechanical

engineers16 professional bearing analysis engineers326 professional

workers83 sets of high precision CNC machine tools32 sets of

bearing testing equipment13,000 square meters factory After

Sales ServiceIn the sales process, we will have professional sales

personnel to answer customers' questions in time, update the

production progress, sort out the photos and videos of packaging

and delivery, provide customers with the required documents; We

will a

Related products about Factory Price Ultrathin Four Point Thin Section Ball Bearing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup