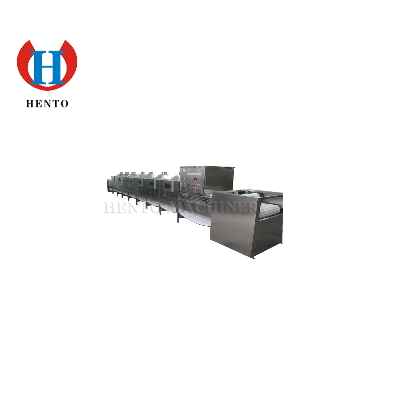

All Stainless Steel Microwave Drying Machine / Microwave Dryer With

High Quality1. Machine Introduction:Design Structure1.All parts of

equipment are made of high quality microwave electric

components A. It use 26 pieces of water cooled magnetrons

which is original Korea Samsung [model OM75P] (rated power 1000 w),

high efficiency, strong ability to resist load, long life. In order

to protect the stability and service life of the magnetron better,

use water cooling protection design of metal ring sleeve type.B. It

adopts special transformer WBL with overheating protection (high

voltage 100 kv transformer, high quality transformer for full

copper core 8.0 kg of a real transformer industry).2.The

distribution design of microwave power1) According to the

characteristics of microwave drying, the power density of the

microwave heater is adopted to strengthen the microwave

distribution mode;2)The chamber of the machine is designed to be 4

boxes, 26 magnetron.3.The machine adopts multi-open feed of heating

body side, well-designed phase form complementary feed mouth

(microwave power density designed according to the feeding

situation), microwave waveguide is designed after a large number of

theory and practices, so as to ensure the normal and complete

operation of magnetron,with superior output matching performance,

the materials heated more evenly and thoroughly,extend the service

life of the core components such as microwave tube and transformer

etc.4.The material of the machine:Special use of 518 mm high box

design process, because the material in the heating and drying

process will heat up, the use of this design can help reduce the

microwave heating the wall surface temperature of the box, and is

conducive to the way of the ideal microwave feed distance.Microwave

heating drying box with 1.5 mm (± 0.2), all stainless steel plate

production, a total of 4 dry sterilization box. Microwave output

port with PTFE plate and special materials sealed. The front side

of the device has a visual observation window to prevent microwave

leakage, easy to observe the material and cleaning, in order to

ensure the safety of the operator, with a special door open power

protection device. Can be washed with water heating box; machine

roller are made of stainless steel, easy to disassemble and

cleaning, spacing 250mm or so. Appearance and the main frame are

made of all stainless steel, beautiful and generous.5.The microwave

power rack designment:1)the microwave generator at the top,

transformers, capacitors installed in the heating box, the

electrical components greatly reduce the working environment

temperature, extend the microwave tube and transformers and other

core original life, to ensure that the equipment to run 24 hours

stable.2) in order to facilitate the placement and maintenance of

the transformer, specially designed for each heating box in the

rear of the way to increase the width of the rear power supply

rack, installation and maintenance can be convenient to

operate.6.The moisture and heat rejection system:Design a separate

dehumidification and exhaust system, using a multi-wing centrifugal

fan for a row of wetting and a number of axial fan exhaust (rear

power supply exhaust). Drain the fan can quickly reduce the

temperature of the box and take away part of the material moisture.

Improve and ensure that the ambient temperature inside the

electrical box, to achieve and ensure that equipment can be

long-term continuous and stable work.7.The transmission

system:1)the use of Nanjing-controlled motor Co., Ltd. three-phase

asynchronous motor for material transmission, and the use of

frequency converter speed control, according to the sterilization

temperature needs to adjust the corresponding speed, the specific

speed range of 0-5 m / Adjustable points.2)according to the

characteristics of materials, special use of food grade PTFE tape

as a material carrier.3)the transmission belt with automatic

positioning device.4)the installation of stainless steel hopper

device (100L), frequency control, the output end with closed

hopper.8.Machine assembling:Equipment modular design, multi-segment

assembly design, easy to transport equipment and to the scene when

the installation can be quickly and orderly assembly.The Control

System1.There are PLC man-machine interface automatic control

system on the front of the microwave suppressor.You can control the

power, transmission speed, drying temperature and other operations

easily.2. It is equipped with one set of infrared radiation

thermometer((LT-05)) produced by German company in section 4 of

microwave heater, so as to timely monitor material temperature

during the drying and sterilizing, and correspondingly adjust the

microwave power, control the temperature of the material.Major

Dispositions1) The heating cavity are made of stainless steel

plate.2) Can feed mouths are sealed by PTFE which is

specially made.3) 26 pieces of water cooled

magnetrons, which are original Korea Samsung or Tos

Related products about All Stainless Steel Microwave Drying Machine / Microwave Dryer With High Quality

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup