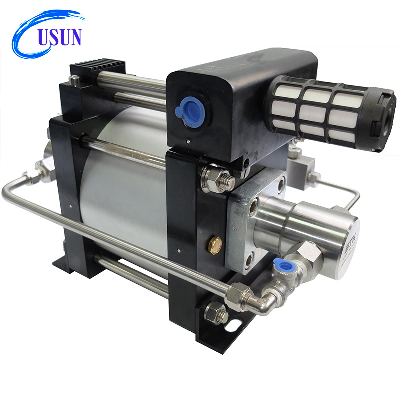

Popular Usun Model :AT -CO2 type 160mm driven

double acting pneumaticdriven Liquid CO2 transfer pump for

tank refilling General Information for Air driven liquid

pumps USUN air driven liquid pumps are

ratio devices that utilize low pressure

compressed air driving a larger diameter piston (area x

pressure) which is linearly connected to a

smaller hydraulic piston/plunger. Using this ratio

principal, a higher hydraulic pressure can be

generated. Usun Pump model numbers reflect the pumps

nominal pressure ratio, while the technical

data indicates exact ratios. The outlet stall

pressure is easy to set by adjusting the air drive

pressure through a simple air pressure

regulator. By multiplying the pressure ratio by the

available shop air pressure, the nominal liquid pressure

can be calculated. Exmple ( Pump Model: AT644 liquid

pump) Air drive piston area ( 160mm Ø) Hydraulic

plunger area ( 20 mm Ø) Actual ratio = 64:1 1.

AIR DRIVE SECTION The air drive section consists of a light

weight piston complete with seals running inside

an aluminum barrel. The diameter of the air piston is

80mm. When compressed air is supplied to the pump the

air pushes the air piston down on a compression stroke (

forces fluid out of the liquid end). Under

the control of pilot pins (poppet valve) triggered at each end

of the stroke 2. HYDRAULIC SECTION (Wetted End) The

hydraulic section of an air driven liquid pump consists of 4 main

pieces, the hydraulic body, the piston/plunger, the check

valves and the main high pressure seal. The

hydraulic piston/plunger is directly linked to the

air piston and it is housed inside the hydraulic body and its

movement up and down creates the liquid flow into and out of

the pump through the check valves. The check valves

are spring loaded and on the suction stroke the inlet check

valve opens to the maximum allowing fluid into the

hydraulic body and on the compression stroke the inlet check

valve closes and the discharge check valve opens forcing the

pumped fluid into the process. The main high pressure seal is

located within the hydraulic body and the piston/plunger

seals against this during operation. There are

different materials and designs of high pressure

seals depending on the fluid being pumped and the maximum

pressures of the pump, however the standard seals

are suitable for both water and hydraulic fluid

use. USUN air driven liquid pumps are self-priming,

However, high ratio pumps are more difficult to Prime and

may require bleeding. In general, it is not recommended to use an

air- line lubricator. USUN air driven liquid pumps cycle

automatically as the outlet pressure increases

the resistance also increases and the cycle rate

decreases until the pump stops automatically when the

output pressure forces are equal. This is referred to as

the stall condition. The pump will restart with a

slight drop in the outlet pressure or an increase in the air

drive pressure. Pump performance can be affected by a

number of conditions, such as freezing of the exhaust

muffler or pilot valves (which is caused by moisture in air

lines), inadequate inlet air-line sizes and dirty

filers. When operating the pumps on a continuous basis, we

recommend you use a maximum cycle rate of 50~60 cycles

per minute. This will both increase service intervals and

assist in preventing ice forming at the exhaust. An air supply

dryer will also assist in reducing icing up. To obtain best

overall performance, it is recommended not to reduce the indicated

port sizes and consult We for flow conditions not shown

in charts.Typical applications for pneumatic driven water

testing pump Key featuresOne model available in 8

ratiosCompatibility with a variety of liquidsSafe pneumatic

operationAluminum bodies and wetted materials of carbon steel or

stainless steelRugged,compact,reliable and easy maintenance proven

designHigh quality seals, long service life availableNo need for

air line lubricationWide application with large range of pressure

ratioMain technical data Typical technical data for pneumatic

driven water pump AT Serial Air liquid

pump Technical

data

Base on air driven at 7Bar , air consumption is around 0.9M3

per min Base on air driven pressure at 7BarModelPiston/Rod

diameter ø(mm)Displacement per stroke (mL)Liquid INLiquid

OUTMaximum outlet pressyre Bar@at 8.3BarLiquid Outlet

pressure (Bar)

1Bar=0.1Mpa=1.019Kg/cm²0204070100150200300400500600700900120017002350Flow

rate

L/min (L/min)AT1050294.52NPT3/4''NPT3/4"8335.3426.5120.6217.6711.78 AT1640188.5NPT3/4"NPT3/4"132.822.6216.9713.211.317.54 AT2035144.32NPT3/4"NPT3/4"16617.3214.4312.9911.5510.10 AT2830106.03NPT1/2"NPT1/2"232.412.7210.69.548.487.426.360 AT402573.63NPT1/2"NPT1/2"3328.847.366.635.895.154.423.680 AT642047.12NPT3/8"NPT3/8"4985.654.714.243.773.32.832.361.881.41 AT801838.17NPT3/8"NPT3/8"6644.583.823.443.052.672.291.911.531.341.15 AT1001630.16NPT3/8"NPT3

Related products about Popular Model: At28-C02 100-200 Bar Pneumatic Driven Liquid CO2 Transfer Pump for Tank Refilling

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup