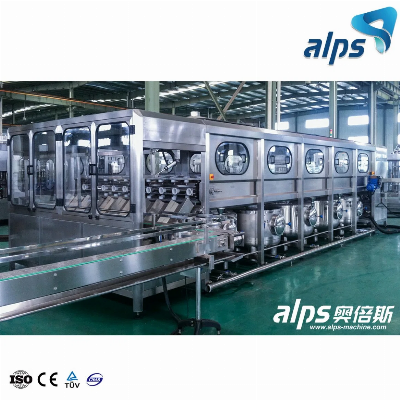

Automatic Pure Mineral Drinking Water 3 to 5 Gallon Bottle Filling

Machine Bottling Plant Production Line for 12L / 15L / 20L

Dispenser BarrelProduct Description *We supply complete

solution for the recycled bucket water bottling machine,including

Water treatment system / Decapping machine / Inside brusher /

Externer brusher / Automatic 5 Gallon rinsing filling capping

machine / Automatic Cap sleeve label machine / Code sprayer / Film

wrapping machine / Automatic 5 gallon palletizer

system Technical parameter:5 Gallon barrel filling

machineModelQGF-100QGF-300QGF-450QGF-600QGF-900QGF-1200Capacity

(for 5 gallon)60-100bph300bph450bph600bph900bph1200bphSuitable

bottle shapesPET circular or squareCompressor air3 & 5 GallonAir

consumption0.3-0.7MpaRinsing pressure0.37 m3/minApplication5 gallin

filling machineTotal power

(KW)1.5kw3.8kw4.5kw5.2kw6.2kw7.8kwOverall

dimensions2.3*1.9m2.5*1.9m2.8*2.15m3.1*2.5m3.8*2.8m4.5*3.3mHeight 1.8m2m2.2m2.3m2.5m2.6mWeight(kg)800kg1500kg2000kg2500kg3000kg35000kgThe

filling line specially for 3-5 gallons barreled drinking water

,with type

QGF-100,QGF-240,QGF-300,QGF450,QGF-600,QGF-600,QGF-900,QGF-1200.It

integrateds bottle washing,filling and capping into one unit ,in

order to achieve the purpose of washing and sterilizing,The washing

machine uses multi-washing liquid spray and thimerosal spray,the

thimerosal can be used circularly,The capping machine can be cap

barrel automatically ,The line equips with water spraying device in

order to ensure those caps sterile and clean ,it also can

automatically carry out

barrel,washing,steriizing,filling,capping,counting and products

discharging,with complete function,modern design and high degree of

automation ,It is a new kind of barreled water auto producing line

,which integrates mechanism,electricity and pneumatics technologies

together Complete Line Flow Chart :1.Decapping Machine ;

2.External Brusher ; 3. Automatic 5 Gallon Rinsing Filling Capping

Machine ; 4.Cap elevator ;5.Code sprayer ; 6.Light checker ; 7.Cap

film shrinker Machine ; 8 .Plastic bag wrapping machine ; 9.Bucket

collect Detailed Photos This machine is a fully

automatic, high intelligent, stable and reliable blowing machine,

with simple structure, and low energy consumption. It is very

popular and well used in 3 - 5 Gallon Bucket Filling industry.

Company Profile Alps Machine Co.,Ltd is ... *Standardized

workshop of total 12,000 square meters. Different types of

processing units, such as water jet cutter, plasma cutter, laser

cutter, CNC machine from Taiwan chevalier & korea daewoo, ensure

the precision of parts. *International certification, National

Certificate of equipment verification, and more than 30 invention

patents Verification Certificates of equipments:

ISO9001:2001; CE Certificate , SGS , COC , TUV National Certificate

of equipment verification:standard organisation of Nigeria , CNCA

certificate, Logo trademark registration, etc. *The equipment will

be tested and run for 24 hours before leaving the factory, to

ensure the smooth working of water pipeline, and pneumatic,

electrical and mechanical stability. *Sufficient stock of spare

parts ensures the timely delivery and supply of spare parts. *The

engineers are experienced. We can produce different products with

different capacity and work out reasonable flow chart as per

customers' requirements to save space. *Professional installation

team who can speak fluent English can help customers make benefits

in a shortest time. FAQ 1.Q:Are you a factory or trading

company?A:We are a factory, professional water treatment system

manufacturer and small bottle water filling & packing machinery

with about 10 years experience. Factory covers an area of 12000

square. There have been more than 50 countries use our

products.2.Q:Where is your factory located? How can I visit

there? A:Our factory is located in Donglai town,Zhangjiagang

city,Jiangsu province,China. about 2 hours away from PVG Airport .

All clients are warmly welcome to visit us !3.How about

installation ?We will send our engineers to your factory to install

the machines and train your staff how to operate the machines.

Customer pay air tickets go and back,accommodation and USD100 /

day/person.4.Q:How long is the warranty of your equipment?A:2 years

warranty after receipt check upon delivery.And we will

comprehensively provide you all kinds of technical support services

in after-sale service 5.Q:What is the features of our

company? A: We provide turnkey project for customers,

including sale and after-sale service; complete production line

equipment supply; bottle design; layout programs provide; or

provide auxiliary materials purchasing agent supplier information;

equipment overseas installation and commissioning; operator

training; etcOur compnay complies with ISO9001:2000 Internation

quality management system,also carries out the modern enterprises

management systme ,to executes quality control during the processes

of producing ,wins customer' recognition b

Related products about Automatic Pure Mineral Drinking Water 3to5 Gallon Bottle Filling Machine Bottling Plant

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup