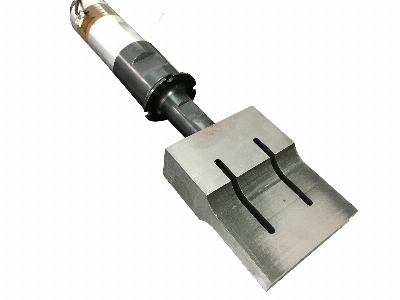

ultrasonic welding sealing horn package sealing machine for tea

packing Ultrasonic products offer clean,

consistent and fast processing for joining and cutting nonwoven

materials. From quilting mattress pads and sewing disposable health

care apparels to slitting and bonding hygiene products we have

designed and delivered a solution for all major film and fabric

applications. We can accommodate your specific needs to design and

build the optimal solution for your material thicknesses and

widths, feed rates and material handling requirements.

Our technical experts are just a phone call away to

answer questions on issues such as: continuous operation and

importance of proper cooling; premature tool wear and the benefits

of carbide and titanium; material handling logistics, coordination

and flow; automation, control and monitoring requirements; required

throughput and maximum quality feed rates. Our

Fabric & Film Technical Center offers a complete range of services:

applications engineering, tooling design, systems integration,

service and support, and training. Most important, the Tech Center

is your resource for information gathering and experimentation on

any of our fully operational ultrasonic machines.Principles of

OperationEvery ultrasonic unit contains the following five

elements:1. A POWER SUPPLY which takes line power at 50 or 60

cycles and changes it to high ultrasonic frequency at 20,000 cycles

per second or even higher.2. A CONVERTER which contains

piezoelectric crystals which change the incoming high frequency

electrical signal to mechanical vibration.3. A BOOSTER which

transmits the vibration energy and serves to increase its amplitude

in much the same way as volume control on a radio.4. A HORN which

delivers the vibration energy to the plastic film or fabric to be

worked on.5. AN ANVIL or backup part which supports the work piece

and, in the case of textiles, takes the form of a pattern wheel or

non-rotating cutter wheel depending on the application.The

ultrasonic vibration is transmitted from the horn to the material.

developing frictional heat where they touch. This momentary heat

fuses the edges of the fabric. If double plies are present, the

plies join together. Where a cutting edge is used on the anvil, the

fabric is cut through and the edges sealed at the same

time. Advantages of Ultrasonic Sealing30-80% narrower seals vs

heatReduction of package headspacePotential reduction in secondary

packagingReduce MaintenanceReduce contamination of sealing

toolsReduce changeover timeEliminate tool cooling timeReduce

EnergyEven temperature distributionSealing times between 80 and 200

msShort cycle timesEstimated ROI from 6 months to 2 years /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Ultrasonic Sealing and Welding Equipment Package Sealing Machine for Tea Packing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup