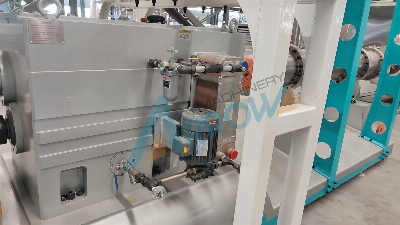

OverviewProduct Description Wide Selection of Gearbox

ProductsThe gearbox usually adopts a general design scheme, but in

special cases, the design scheme of the gearbox can be changed

according to the demands of the user, and it can be modified into

an industry-specific gearbox. In the design scheme of the gearbox,

the parallel shaft, vertical shaft, general box, and various parts

can be changed AdvantagesAbsorption of very high torques and axial

forcesNo need for separate thrust housing & bearing.Easy alignment

(screw directly fits into the vore of gear box)Easy to assemble &

dismantle.Very heavy duty spherical roller thrust bearing is

provided.Power saving. (you may save up to 20 % power.)Less

requirement of space.For bigger sizes water cooling is

provided No maintenance required except periodic oil level

checking.Higher productivity Features Twin Screw

Extruder Gearboxes offer the dual shaft counter rotating. The range

is available for various center distances The gearboxes are

available with co-rotating and counter rotating variants To work

under heavy loading force, the high level dissipation and oil

lubrication system are provided. The axial roller type swivel

thrust with the thrust bearing coupled in tandem way support the

axial thrust High torque and high speed output rate

Processing Characteristics of Screw Shaft:1.Suitable suggestion on

material to ensure components performance and extend lifetime of

products.2.Professional technical team can provide surveying and

mapping support.3.All components are finished by CNC

machine.4.Sophisticated quality management system ensure superior

quality. Basic Info. Warranty: 1 yearWeight (KG): 500

KGPlace of Origin: Jinan, ChinaGearing Arrangement:

helicalratio:8-20Output Torque:2*176 standard:

JB/T8853-2001Certificate: CEHeat treatment:High-frequency

HardeningEfficiency:94%~98%(depends on the transmission

stage)Customized support:OEM ODMInput/output shaft

material40CrPackage:Wooden case Mount position:Flange, hollow

shaft, solid shaftAfter-sale:Online 24/7 Installation

Guideadvantage:excellent qualityReduction radio:3:1 Mount

Position: Horizontal Foot Mounted Vertical Input

Speed:1500 Output Speed:500 Packaging &

deliveryPacking: wooden case packing Port: Qingdao

Port ApplicationsX helical gear units for double-screw

extruders with parallel drive shafts and the same direction of

screw rotation are used mainly in the manufacture of granulates and

the refining of raw plastics. Other areas of application

include:Paint and lacquer industryWashing agent industryFoodstuff

industry (e.g. bread, pasta)Animal-feed industry (dog, cat other

animal food Maintenance of the gearbox of the dual-screw

extruder1. The gear box of the dual-screw extruder should be

well-ventilated, and the working environment temperature should be

within the range of 5-35 °C.2. Always check the oil quantity of the

gear lubricating oil in the box to ensure that the transmission

parts in the box are well lubricated.3. Pay attention to check the

bearing parts of the box frequently. The oil temperature of the oil

tank of the transmission box should not exceed 70 ºC during

operation.4. The newly put into use gearbox needs to replace the

lubricating oil after 250 hours of operation. The oil change time

depends on the state of the oil. It is recommended to replace it

after 4000-8000 hours of operation or once a year.5. The gearbox of

the dual-screw extruder needs to be regularly maintained and

inspected once a year Operating Process1. The gear on the

input shaft is driven by the motor and starts to rotate.2. The

rotating input gear meshes with other gears inside the gearbox,

transmitting power.3. Different-sized gears within the gearbox are

combined to form a gear train. Through continuous meshing and

rotation, the high-speed, low-torque power from the input shaft

gradually converts into low-speed, high-torque output.4. The output

shaft is connected to the last gear and transfers the output torque

to the load.5. Gear reduction gearboxes typically include

lubrication and cooling systems to ensure smooth operation and

prevent overheating and damage.6. Our extruder gearbox converts

high-speed, low-torque power into low-speed, high-torque output by

changing the size ratios and meshing arrangements of different

gears, achieving the function of speed reduction.Types of

Gearboxes:Based on customer requirements, gear reduction gearboxes

can be classified according to the size of the output shaft, center

distance of the output shaft, output speed, and torque.

Alternatively, we can provide several commonly used types of

gearboxes for customers to choose from.Product Service24-hour

Hotline No matter when and whereto call we can find our

service to you. Pre-sales Consultation We have five

sales people online,and whether you have any questioncan be solved

through onlinecommunication.After-sales Services Receive

products have anyquestions about the product,can look for us,we

will helpyou deal with the the firs

Related products about Speed Worm Gear Box Reducer with Manufacture Factory

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup