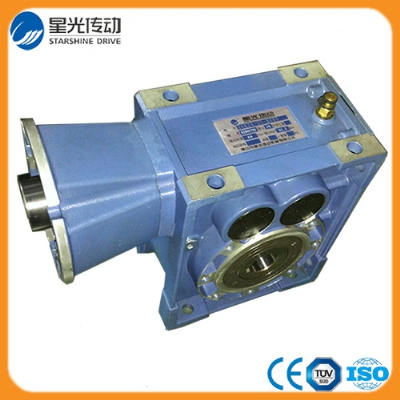

XGK Series HELICAL-HYPOID GEAR UNITS The hypoid gear has low

friction, efficiency is as high as 92%,compared with the worm

gearbox ,the efficiency improved about 10%-40%.The hypoid gear made

of high quality alloy,treated by surface hardening,and produced by

high-precision grinding machine, the output torque,gear strength

and life are much better than worm gearbox.Characteristics1.Larger

reduction ratio with hard surface hypoid bevel gear and helical

gear drive2.Big output torque, high transmission efficiency,

energy-saving3.Fine casting of aluminum alloy, light weight,

rust-proof4.Stable transmission, low noise, suitable for the

terrible working condition5.Good appearance and durability small

volume6.A variety of mounting positions, wide application, easy

using7.Mounting dimension is interchangeable with RV series worm

gear reducer8.Modularity on design:Input: connected with IEC

standard flange motor and servo motor with multiple

specificationsOutput:hollow shaft and solid shaft9.Multi-stages

gear drive. It is divided into two-stage drive(one hypoid bevel

gear and one helical gear) and three-stage drive(one hypoid bevel

gear and two helical gears). Compared with RV series worm gear

and worm shaft structure, it has more refined ratio and wider

applicationABOUT STARSHINE DRIVE Guangdong Starshine Drive

Co.,Ltd(Starshine) have a strong technical force with over 350

employees at present, including over 30 engineering technicians, 30

quality inspectors, covering an area of 80000 square meters and

kinds of advanced processing machines and testing equipments. We

have a good foundation for the industry application development and

service of high-end speed reducers & variators owning to the

provincial engineering technology research center,the lab of gear

speed reducers, and the base of modern

R&D.Our products are widely used in ceramic

industry, glass industry, woodworking machinery , high voltage

switch, food & beverage, packaging & printing, Storage & logistics,

hoisting & transportation facilities…etc , and Starshine

technically provide the professional product & service for the

medium and high-end customers, and our gearboxes are best-selling

in domestic, and even in abroad , such as in Europe, North America,

South America, Middle East, South Asia, Southeast Asia,

Africa…etc. In the future , Starshine will hold the creed of

"serving customer, diligence & simplicity, self-criticism,

innovation, honesty, teamwork", and the concept of "quality creates

value" to focus on the customers' requirements and provide them the

competitive transmission solution and create value for them

constantly, and make a high-end equipment manufacturing industry

and create a preferred brand of replacing import products and

upgrading continuously for the end users. TEAM QUALITY

CONTROLQuality:Insist on Improvement,Strive for Excellence With the

development of equipment manufacturing indurstry,customer never

satirsfy with the current quality of our products,on the

contrary,wcreate the value of quality.Quality policy:to enhance the

overall level in the field of power transmission Quality

View:Continuous Improvement , pursuit of excellenceQuality

Philosophy:Quality creates value3. Incoming Quality ControlTo

establish the AQL acceptable level of incoming material control, to

provide the material for the whole inspection, sampling, immunity.

On the acceptance of qualified products to warehousing, substandard

goods to take return, check, rework, rework inspection; responsible

for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.4. Process Quality ControlThe

manufacturing site of the first examination, inspection and final

inspection, sampling according to the requirements of some

projects, judging the quality change trend; found abnormal

phenomenon of manufacturing, and supervise the production

department to improve, eliminate the abnormal phenomenon or state5.

FQC(Final QC)After the manufacturing department will complete the

product, stand in the customer's position on the finished product

quality verification, in order to ensure the quality of customer

expectations and needs.6. OQC(Outgoing QC)After the product sample

inspection to determine the qualified, allowing storage, but when

the finished product from the warehouse before the formal delivery

of the goods, there is a check, this is called the shipment

inspection.Check content:In the warehouse storage and transfer

status to confirm, while confirming the delivery of the product is

a product inspection to determine the qualified

products.PACKING DELIVERY /* January 22, 2024

19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Helical Hypoid Spiral Bevel Gearbox with Motor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup