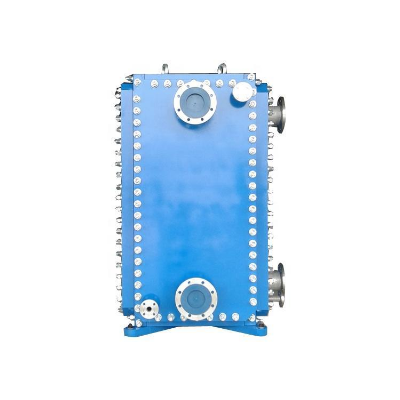

PRODUCT DESCRIPTION Fully welded plate and shell heat

exchangerMany steel plates is being welded together to form

heat transfer unit on stacking one by one, then fixed and

covered by steel frame and long bolts for comprising the all welded

heat exchanger, which has no leakage point completely. Two

non-interference flow channels in the core works on the

heat exchanging effectively. The constant pressure plate

moulding and exact thin plate welding process is the core

technology on manufacturing.Advantages aspects: High heat

transfer efficiency. Corrugated SS steel welding unit is the core

of HE for forming the flowing bundle influenced, increase the

heat exchanging efficiency. Low pressure drop. In the same

heat transfer area, circulation area of all-welded plate heat

exchanger circulation area is about more five times

than that of tubular heat exchanger.The

core is assembled by thin plates, which is 0.5 to

1.2mm thickness for compact structure and light weight

processing, that saves more cost,place and volume comparing with

tubular heat exchanger.

Applied fields: PetroChem, FineChem,Pharmaceutical,

Pesticide, Sugar, Beverage, Oil. etc.Heat Exchanging Gas-Gas,

Liquid-Liquid, Gas-LiquidPlate Material304,316L, AL-6XN, Hastelloy

C-276,254MO, Ni, Ni alloy, TiDesign Pressure3.2MpaDesign

Temperature350ºCManufacturing StandardASME,

Nb,GB150,ASA150CertificateISO9001,ISO14001,ISO18001,ASMEDeliver

Timewithin 60days except specifiedPackingExporting seaworthty

standard packageShippingChina base seaport COMPANY

INTRODUCTION Who are usShandong WINTECH Technology Co., Ltd.

(hereinafter referred to as WINTECH) is located in Zichuan Economic

and Technological Development Zone, Shandong Province. It is a

high-tech enterprise that develops and manufactures high-efficiency

energy-saving heat transfer products. Its core technology has

independent intellectual property rights, and has won many

provincial or national awards. It is a strategic emerging industry

project vigorously advocated by the state. WINTECH has a complete

product system, including Fully welded plate heat exchanger, round

plate and shell heat exchanger, semi-round plate and shell heat

exchanger, air preheater, slurry heat exchanger, GGH heat

exchanger, etc. The above products can meet different working

conditions of users,WINTECH provides customized products according

to the different needs of users ,its products are widely used in

petrochemical, electric power, steel, metallurgy, shipbuilding,

pharmaceutical and other fields, with Significant features such as

energy saving, emission reduction, high efficiency and practicality

,high added value. It is of great significance to promote the

development of new efficient, energy-saving and emission-reducing

heat transfer industries.WINTECH has always adhered to the value of

"integrity, customer achievement, entrepreneurship and innovation,

teamwork". The production process strictly abides by the relevant

national and industry standards. The product has formed a perfect

quality assurance system from design, manufacture to inspection. It

has obtained ISO 9001 quality management system certification, ISO

140001 environmental management system certification, ISO 18001

occupational health and safety management system certification, A2

pressure vessel manufacturing license, the introduction of advanced

testing equipment and means at home and abroad have laid a solid

foundation for improving the stability and reliability of products

and won the trust of users.What's product we manufactureWhy choose

usWe set up all art state of facilities on processing from the

uncoiling steel machine, hydraulic oil pressing machine,

Gantry milling, resistance welding machine, welding robot, Laser

welding machine,testing from complete instruments in our lab, make

every set of equipment is dispatched at the qualified

controlling. Basing on our powerful product capability, many

certification and awards are achieved. ISO14000, ISO9000,

OHSAS18001, CNAS, IAF, ASME make us prodce and supply equipment as

per the ASME standard complying with international market

consumption, now our clients are from Russia, Uzbekistan, Thailand,

South America, India,Indonesia, Malaysia,Iran, Saudi Arabia,

Argentina, and other countries and areas.Part of projects /*

January 22, 2024 19:08:37 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about All Welded Plate and Frame Heat Exchanger for Refinery

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup