About UsGreenfir is a professional natural gas processing &

liquefaction plant, air separation unit, heat exchanger,

reciprocating piston compressor, cryogenic cold box, fractionating

column manufacturer and solutions provider with ISO 9001: 2015, ISO

14001: 2015, ISO 45001: 2018 and ASME U certified.We offer

skid-mounted solutions optimized for each specific project,

covering the following applications: Air Separation Plant, LNG

Plant, Gas Purification & Liquefaction Unit, CNG/ LNG/ L-CNG

Filling Station, Flare Gas Recovery Unit and Hydrogen Purification

Unit, etc. We can deliver skid-mounted solutions customized to meet

client's challenges and requirements (including adverse weather

conditions, transportation and plot area limitations, etc).We treat

all the cryogenic solutions with serious attitudes and professional

experience. Combined with our knowledge and experience, Greenfir

provides each client with a technology-leading solution you can

count on and bring a wider range of options and more

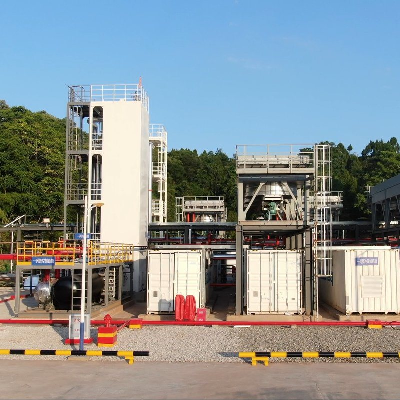

profits.Product DescriptionMini and Small-Scale LNG (MSLNG & SSLNG)

plant is the use of small liquefaction and regasification

facilities that enable flexible supply chains to deliver to

multiple smaller distributed users. These users would normally

consume energy with short supply agreements, at lower quantities or

in remote locations that would previously be unserved by

conventional natural gas infrastructure.Greenfir has years of

valuable experience in developing liquefaction technology for small

scale applications. We understand the importance of operational

simplicity, flexibility, efficiency, equipment robustness, and a

compact footprint when dealing with mini and small scale LNG

projects.Advancing technology is making even smaller units feasible

and opening up new markets. LNG can be transported by road or train

to be delivered into skid-mounted storage at the point of use,

providing flexible and deployable energy at significantly reduced

costs to the user.Process TechnologyGreenfir liquefaction

technologies are mostly based on the MR (mixed refrigerant)

technology. It is designed with a closed loop refrigerant cycle,

thereby eliminating make-up or chemical/ logistics handling for the

refrigerant. The main elements of the plant are as listed below,

while different modules can be incorporated to improve the

efficiency of the plant according to the specific project

requirements.Main SystemFiltering & Metering SkidGas Purification

System (Acid Gas Removal package, Dehydration Package, and Mercury

Removal Package)Liquefaction (Cold Box, MR Compressor, etc.)LNG

StorageLNG Loading SystemUtilities (Instrument Air & PSA Nitrogen

Generattion Package, Demineralized Water System, Hot Transfer Oil

System)Instrumentation Control System Electrical Control SystemFeed

Gas Booster Compressor(s) (Optional)Nitrogen Removal Column

(Optional)Heavy Hydrocarbons Separation (Optional)Biol-off Gas

Handling (BOG Compressor) (Optional)Power Generation

(Optional)etc.Customer Benefits- Robust and reliable

technology that is simple to operate.- Designed for unmanned

operation.- Easy start-up and shut down of all

systems.- Quick and easy capacity control.- Compact and

modularized design ensures easy shipment and cheaper

installation.- The lowest specific power consumption in small

size plants.- All components based on conventional parts and

proven technology -> Spares can be delivered quickly.-

Reliable main rotating machinery with high efficiency.- Local

control of LNG export -> truck driver handles the

loading.- Fast project delivery time (FOB 7 months for the

MRC Process).- Broad range of applications, biogas, pipeline,

CBM and associated gasReference ListProjectScope of

SupplyCapacityQuantityLocationYearNatural Gas Purification,

Liquefaction Plant50,000 Nm3/day Wellhead Gas Recovery

ProjectEPC 1ChinaNov. 201630,000 Nm3/day Mini LNG

PlantEPC 2ChinaMay, 201730,000 Nm3/day Wellhead Gas Recovery

ProjectEPC 1ChinaMay, 201730,000 Nm3/day Mini LNG

PlantEPC 1ChinaNov. 201850,000 Nm3/day Wellhead Gas Recovery

ProjectEPC 1ChinaNov. 201960,000 Nm3/day Mini LNG

PlantEPC 1ChinaNov. 2018Demethanizer and Deethanizer

Rectification SystemEP20,000 Nm3/day KazakhstanJul. 2020CNPC

100,000 Nm3/h Mini LNG PlantEPC 2ChinaJan. 2021ARV 50 TPD Mini

LNG Plant ProjectEP, Supervision Commissioning & Start-up50

TPD1IrianApr. 2021MAN 3.5 MMSCFD Mini LNG Plant ProjectEP,

Supervision Commissioning & Start-up3.5 MMSCFD1IrianApr. 202150,000

Nm3/day Mini LNG PlantEPC 1ChinaAug. 2021Ethylene Compressor

StationEP, Supervision Commissioning & Start-up17.88

MMSCFD IrianApr. 2022MAR 20 MMSCFD Amine Sweetening Package

ProjectEP, Supervision Commissioning & Start-up20 MMSCFD1IrianDec.

2022KHE 13 MMSCFD Field Flare Gas Recovery ProjectEP, Supervision

Commissioning & Start-up13 MMSCFD1IrianDec. 2022100,000 Nm3/h Mini

LNG PlantEPC 2ChinaDec 2022Deethanizer Rectification

SystemEP30,000 Nm3/day1KazakhstanMar. 2023 /* January 22,

2024 19:08:37 */!function(){function s(

Related products about LNG or Asu Plant Liquefaction Cold Box with Pfhe Plate-Fin Heat Exchanger

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup