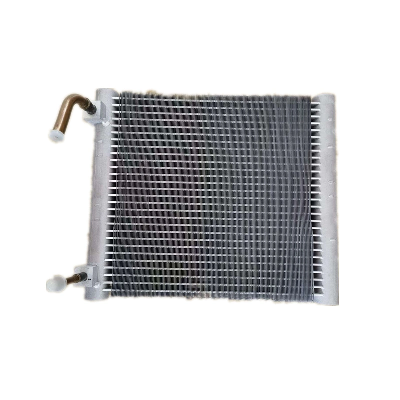

Product DescriptionMicro channel evaporator coils are increasingly

becoming a necessary technology, and many industries are beginning

to choose to use microchannels instead of traditional coils on both

the condenser and evaporator sides. An air conditioner unit

with an evaporative coil utilizes no more than 20% of the coil

area, if the evaporative coil is replaced with a micro channel

evaporator coil, the advantage is huge as it can utilize

microchannels only for the surfaces that are needed , saving a lot

of money. Micro Channel Evaporator Features: Custom

& Standard SizesFlexibility and variable dimensions are tailored to

our OEMVertical MicroChannel TubesHigh Water Shedding & High

Performance Fins Micro channel evaporator coil

advantage:Improved heat transfer performanceLow temperature start,

defrost drainRefrigerant charge is reduced (compressor power is

reduced, power consumption is reduced)Cost advantage, low

procurement cost;It can handle a combination of dry, condensation

and frost/defrost conditions for indoor and outdoor heat

exchangers.All products are tested for helium and ultrasonic leak

detection before delivery.Optional anti-corrosion

process: painting, spraying, electrophoresis,

nano-coating. The MicroChannel coil has been designed as a

high performance Evaporator to tackle sensible and latent

(dehumidifying) heat transfer, plus have the versatility for

operate in reverse as a condenser. It could be used as Cooling

Coils• Make Up Air• Heat Pump (indoor coils)• Heat Pump (outdoor

coils)• Dehumidfier Coils Micro channel evaporator coils can

be used in the following industries:Heat Pump UnitIndustrial drying

equipmentHotel dryerAir-cooled dehumidifier (for basement,

exhibition hall, high-speed, underground warehouse and

more)Industrial Air Cooled Chillerrooftop air conditioning unit

machineAir energy water heater Etc. Hydrophilic coating,

defrosting process: Our AdvantagesWe have customized products

for many customers, following are some projects we did before.We

can provide designing data and prodcution drawings.We promise we

use the design software sold by a well-known European HAVC software

company. Through 8 years of cooperation with them, we have

designed, processed and exported dry coolers to various countries

all around the world. All of customers feedback is that the actual

cooling performance is almost the same as the theoretical design

value. Packaging & ShippingThe normal package is wooden box.

If export to european countries,the wooden box will be fumigated.If

container is too tigher,we will use pe film for packing or pack it

according to customers special request.Lead Time: 20 - 40

days Payment Terms: 50% T/T payment in advance, 50% T/T

payment before deliveryPacking Condition: Standard export

packing or customized packaging Company ProfileWe specialize

in designing, manufacturing and exporting refrigeration

equipments for the varied industries since 2004.When it comes

to building heat exchanger for any application VRCOOLERTECH Company

has the capability to meet your requirements. If you need

a heat exchanger using water, steam, refrigerant, glycol,

ammonia, CO2 or any other medium, Vrcooler can build it for you. We

build heat exchanger for replacement of existing heat exchanger or

for new jobs, as well. We make standard copper tube / aluminum

fin commercial heat exchanger and we build heavy industrial heat

exchanger for process applications. You will be hard-pressed to

come up with a job we can't handle.Our main products:Tube and

Fin Heat ExchangerFinned Tube Heat ExchangerDry coolerUnit

coolerAir Compressor CoolerCharge Air CoolerGenerator CoolerSend

Message to Us Get a Quote! /* January 22, 2024 19:08:37

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Transverse Finned All-Aluminum Micro Channel Parallel Flow Heat Exchanger

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup