Plate materials and the gasket materials mainly depend on

the corrosive properties and temperatures of the cold exchange

medium and the heat exchange medium. The plate heat exchanger's

plate materials and corresponding applicable places are given in

Table 1 and its gasket materials and corresponding applicable

places in Table 2 for your reference. Table 1

Plate Materials Material nameThickness

(mm)Material gradeApplicable placeStainless

steel0.5-0.8304,321,316,316LPlaces with serious corrosion caused by

acid or base mediums and places not suitable for chloride

ions Commercial pure titanium0.5-0.8TiAlkali or salt

making places, sea water desalination places, low-temperature

places, freezing places or places with chloride-ion

corrosionNickel0.5-0.8NiPlaces resistant to corrosion, hot alkali

liquor corrosion, neutral solutions or subacid

solutionsAcid-resistant steel0.5-0.8RS-2, SM0254, HC-276Sulfuric

acid field and the fields with acid corrosionTable 2

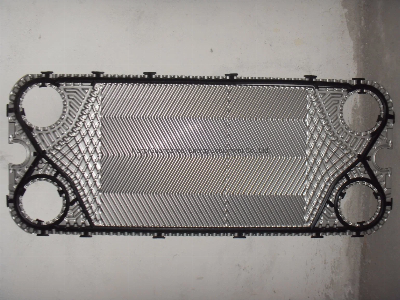

Gasket MaterialsIntroduction to Sealing Gasket

Sealing gasket is inserted and fixed to

the slot in heat-exchanging sheet, featuring easy insertion and

replacement of sealing gasket, which can substantially reduce

stoppage time.Sealing function is separated from fixing function.

Even if some "clamps" with fixing function fail, the gasket can

still have sealing function in the slot. Material nameCode

Applicable temperatureApplicable placeNBRN-20~110ºCWater, non-polar

oil, mineral oil, lubricating oil, silicon oil,

etc.EPDME-20~150ºCSteam, water, ozone, polar chemical mediums,

alcohol, weak acids, weak bases, salt solutions, etc.Chloroprene

rubberC-40~100ºCAmmonia, mineral roil, lubricant, freon,

etc.FluororubberF0~180ºCInorganic acids, bases, mineral oil,

halohydrocarbon and oxidantSilicon rubberQ-40~200ºCFood field,

etc.Flange and connection tube Flanges and connection tubes are the

interfaces between the plate heat exchanger and other heat exchange

systems. Their materials include 304, 316L, 316, 321, TA1,

20# and so on. Their specifications may be subject to

GB9113-88 or customized. Q&A1. Q: How long can we deliver

goods?A: It would be 15-25 days after payment and drawing sketch

confirmed2. Q: Can your company supply an after-sales warranty?A:

Yes, we can supply 1-year after-sales warranty against B/L date.3.

Q: What payment terms can you accept?A: We can accept L/C, T/T,

etc.4. Q: Can you accept customized order?A: Yes, we accept, we

have a very professional technical group who can design the

special products according to your basic parameter/ data sheet/

drawings or sample.5. Q: Do you have your own factory or just you

are a trading company?A: We are the direct factory group, one

is in Guangzhou City, Guangdong Province, another is in Huanggang

City, Hubei Province.6. Q: Is OEM order acceptable to your

company?A: Yes, OEM is Welcomed.7. Q: What kind of equipment used

for manufacturing process?A: A series of high-tech equipment used

in the process of manufacture, including special

hydraulic machine for plate heat exchanger, CNC automatic

cutting machine, automatic wheat arc welding machine,

automatic plasma welding machine, CNC plate winding machine,

shearing machine and etc. 8. Q: What

are certificates and soft power used in

manufacturing process?A: Tranp has obtained ISO9001

certification, CE certification, standardized enterprise

certification and various utility model patent certificates, with

professional engineering and technical personnel engaged in the

design of heat exchange equipment, thermal system and

environmental recovery system. We will help customers to

qualify CE certificates or other foreign certificates in different

area all over the word.9 .Q: What material and

standards used for products?A: All the products are

manufactured as per national

standards,including TSG21-2016, NB/T47004-2009, GB150.1-4-2011, GB/T1512014, GB/T14296-2008

and etc. 10.Q: What is quality inspection procedure to

maintain product quality?A: Tranp has provided professional

inspection regulation for Final quality controls for all products,

to strictly control the quality of products from our

warehouse. /* January 22, 2024 19:08:37 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Gasket for Manufacturing Seals for Plate Heat Exchanger Units

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup