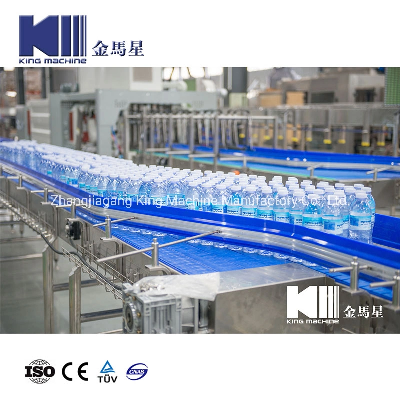

Description: 1.Stable conveying, using synchronous chasing control

between the conveying belt and engine, making bottles in good

condition in the conveying: non-falling, non-block,

non-jam. 2. Conveying belt is designed by module,

component can be interchanged easily, with compact structure, low

noise, easy assembling and maintaining, good flexibility

to combine the bottle type according to the different

capacity. 3. The design of electrical control is

advanced and rational, we can design the control method

, select the electrical control component according to client's

layout, to improvethe conveying stability 4. Set the

switch according to conveying system layout or customers'

reasonable requirement, for the convenience of operation.5.

Belt lubricating system is equipped6.Main part all using ANSI3047.

Fringe board is using the U.S. Rexnord technology to

produceSpecification:1.Conveyor Height:1050mm2.Side panel: 304

stainless steel sheet, thickness is 2mm3.Motor: 0.75KW 4.Supporting

leg: 304 stainless steel 5.Trunking and cover: 304 stainless

steel6.Lubricant water conservation tank: 304 stainless

steel7.Chain plate: Domestic high-quality plastic chain

plate,polyoxymethylene (POM)8.Bearing housing: 304 stainless steel

cageZhangjiagang King Machine Co., Ltd.Is a group company

located in Zhangjiagang city, we have more than 15years experiences

on beverage machinery and plastic machines.We devote ourselves to

the development, research and production of plastic machine and

liquid food and beverage packing and filling industry and automatic

blow molding machine in China.Our Main products including:Mineral

water and purified water producing line.Carbonated beverage

producing line.3 gallons& 5gallons producing line.Flat and tube UHT

device, and CIP system.All the products are sold well in every

province and city of the whole country and also exported to about

thirty countries and areas with strong technical force, advanced

equipment, scientific management system and perfect after-sales

service.Our Main Products Likes:1000-15000bph water productione

line1000-15000bph juice production complete line1000-15000bph

carbonated drink production line1000-15000bph wine bottling

line1000-9000cph canning line1000-6000cph Oil filling line5gallon

bottle filling lineStand alone machines also availableWelcome

Customers Visit Our Company.King Machine Standardized workshop of

total 21,000 square meters. Different types of processing units,

such as water jet cutter, plasma cutter, laser cutter, CNC machine

from Taiwan chevalier & korea daewoo, ensure the precision

of parts. International certification, National Certificate of

equipment verification, and more than 30 invention patents are done

in King machine . Verification Certificates of equipments:

ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard

organisation of Nigeria , CNCA certificate, Logo trademark

registration, etc. The equipment will be tested and run for 24

hours before leaving the factory, to ensure the smooth working of

water pipeline, and pneumatic, electrical and mechnical stability.

Sufficient stock of spare parts ensures the timely delivery and

supply of spare parts. The engineers are experienced. We can

produce different products with different capacity and work out

reasonable flow chart as per customers' requirements to save space.

Professional installation team who can speak fluent English can

help customers make benefits in a shortest time. King

Machine1. Installation, debugAfter equipment reached the workshop

of customer, place the equipment according to plane layout we

offered. We will arrange seasoned technician for equipment

installation, debug and test production at the same time make the

equipment reach the rated producing capacity of the line. The buyer

need to supply the round tickets and accommodation of our engineer,

and the salary. 2. TrainingOur company offer technology training to

customer. The content of training is structure and maintenance of

equipment, control and operation of equipment. Seasoned technician

will guide and establish training outline. After training, the

technician of buyer could master the operation and maintenance,

could adjust the process and treat different failures. 3.

Quality guaranteeWe promise that our goods are all new and not

used. They're made of suitable material, adopt new design. The

quality, specification and function all meet the demand of

contract. We promise that the products of this line could storage

for one year without adding any aseptic. 4. After salesAfter

checking, we offer 12 months as quality guarantee, free offer

wearing parts and offer other parts at the lowest price. In quality

guarantee, the technician of buyers should operate and maintain the

equipment according to seller's demand, debug some failures. If you

could not solve the problems, we will guide you by phone; if the

problems are still can not solve, we will arrange technician to

your

Related products about Water Bottle Flat Conveyor with Motor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup